Spare parts for washing machine

The washing machine is rather complicated in technical terms, a device consisting of a certain number of electrical and mechanical parts housed in a housing. Some of these items eventually wear out or fail in emergency order. To eliminate all sorts of faults will require spare parts for washing machines, which can be purchased in specialized stores or on the Internet. Among the variety of elements that make up the washing machine, you can select components and parts that are most susceptible to stress and affect the performance of the unit.

Content

Control board

Under her control are all the processes occurring during the execution of washing programs. Guided by signals from various sensorsinstalled in the main units of the unit, the control board determines:

- the moment when you need to open the valve to fill the water, and when to close it;

- when it is required to turn on the heating element to heat water, and at what temperature of the liquid it is turned off;

- in what directions and with what intensity should the electric motor turn the drum;

- after what time to start the pump (pump) for pumping water from the tank;

- when commanding the engine to turn on the high revs necessary for spinning, etc.

If the control board fails - and this can happen for various reasons, for example, when a voltage surge in the network or breakdown of the heating element to the unit housing, the machine simply does not start or starts to work with errors.

You should know that this module is the most expensive and complex element of the washing machine. Therefore, when it breaks, it is recommended to call a specialist from the service center that repairs washing machines. The master will be able to identify the fault and, if possible, eliminate it.But most often, the repair control module can not be, and it is required replace with a new one.

Engine

The main task of the electric drive is to make the drum spin. The rotational movement from the engine to the drum is transmitted through belt drive through pulleys. But in some models of washing machines the engine is mounted on the drum itself - this is called direct drive.

The failure of the engine can be determined by the following features:

- the drum stopped rotating during the execution of the program;

- the engine does not rotate, the smell of burning wiring is heard;

- the engine does not develop the required power (can not crank the drum), while it is very hot.

Important! It should be borne in mind that the latter problem may also occur when the electrical brushes are worn.

If at least one of the above symptoms is noticed, the repair of the electric drive should be carried out by a specialist who will determine where the device has been closed or the windings have broken. But first, the master will have to check the washing machine enginewithout removing it to make sure that the problem is here.

Buck and Drum

These parts are interconnected by means of the gland and the bearing. The tank and the drum perform the following functions.

- Tank is a container made of plastic or stainless steel, in which water is drawn for washing. The drum is placed in the tank, the heating elements and the water level sensor are installed.

- Drum is a stainless steel cylinder. Throughout its area, many small holes have been made, through which water flows from the tank. Also inside the cylinder there are special ribs that facilitate turning the laundry during rotation.

The drum tank is the largest part of the washing machine.

The main symptom of damage to the tank is leakage due to the formation of cracks. Since the tank, in most cases, is made of plastic, it makes no sense to solder it (this is short-lived). It is better to replace it with a new one, especially since the price of plastic tanks is not that high. To remove the replacement tank, you will need disassemble the washing machine.

Important! The appearance of a puddle under the unit can also be caused by the sealing cuff of the door of the machine, which is either deformed or torn. In this case, the cuff should be removed, to replace or to glue up.

The drum itself rarely fails. Sometimes he damaged by metal partsthat may be present on the items loaded for washing. If this happens, you will need disassemble the washing machine drum and replace it with a new one.

Shock absorbers

Located in the lower part of the apparatus and are intended for damping tank oscillationsarising in the course of work.

If you began to notice that your typewriter had vibrations that were not previously observed, or knocking was heard when the drum rotates in spin mode, then you will need replacement of shock absorbers.

Brushes on the engine

Special electrodes, called brushes, are used to transfer electricity from the power source to the engine manifold.

Electric brushes are an integral part of all collector engines. These drives are equipped with washing machines of brands such as Indesit, Samsung, Veko and others.

Over time, when the electrodes are worn, contact with the collector is broken, and the engine stops working in normal mode or stops completely. The main signs of brush wear are strong sparking in the reservoir area engine and power drop of the drive. Replacing brushes - The process is quite simple and does not require the participation of a specialist.

Bearing

This part is installed in the gland of the tank and provides drum rotation with minimal resistance.

The bearing may become unusable due to normal wear or, what happens more often, due to a faulty oil seal that starts to leak water. If moisture gets on the bearing parts, they start to rust and very quickly collapse.

If the bearing breaks down, you can hear the screech, crackling and other noise in the area of the drum during operation of the unit. Also, the noise does not stop if you twist the drum manually. Replace bearing slightly more complicated than, for example, changing the heating element or pump. But nevertheless, it is quite possible for any home master to perform this task.

Stuffing box

To connect the drum with the tank, which is a fixed part of the washing machine, and there was no water leakage, use a special rubber ringcalled the gland.

The gland also does not allow moisture to enter the shaft and bearings mounted on it. As it is not difficult to guess, if the gland is damaged, then the surest sign of this failure is the appearance of puddles under the washing machine. To replace the gland, you will need to remove the belt, pulley and disconnect the drum.

Heating element

The main function of the heater is heating water in the tankin which it is installed.

Important! The heater often fails due to “fouling” with scale if the user of the washing machine did not take steps to remove it.

The burnout of the heating element is sometimes accompanied by a loud bang and sparking in the back of the unit. This means that a short circuit has occurred (the heater struck the casing). To replace the heaterNo special knowledge required. It is enough to remove it, read the label and purchase a heater with the same parameters.

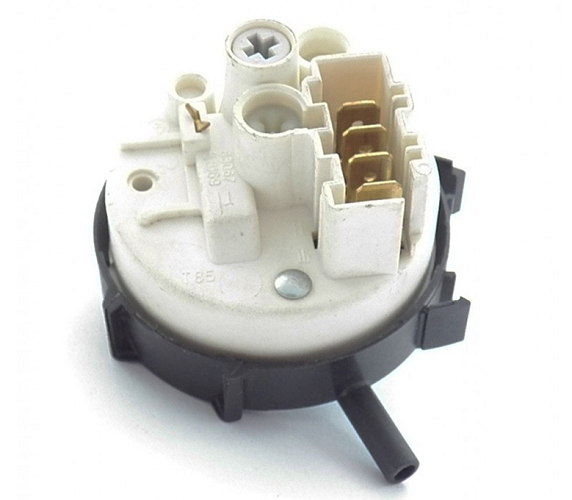

Water level sensor (pressure switch)

The main purpose of the pressostat is water level controlpoured into the tank. The sensor determines whether there is enough water in the tank depending on the requirements of the wash program.

The pressure switch consists of a relay and a small tube placed in the tank. When a certain pressure in the tube is reached, the rale opens and signals the control board that there is enough water in the tank for washing. In turn, the control module closes the solenoid valve responsible for supplying water to the apparatus’s tank.

If the water level sensor breaks, it can do not dial or dial without stopping. In this case, the problem is solved. pressure switch replacement.

Drive belt

With the help of a belt, as mentioned above, the rotational motion is transmitted from the engine to the drum. The belt is put on the pulleys of both parts and is taut.

The fact that there was a rupture of the belt can be understood by several signs:

- The drum is not spinning.

- A silent engine operation is heard. It means that the belt is broken or just flew off and lies at the bottom of the case.

- Loud claps are heard. This means that the belt is wound on the engine pulley. In this case, turn off the machine so that the rotating parts of the belt do not damage the wiring inside the machine.

Belt replacement will not cause difficulties even for a beginner. The main thing to buy this item in accordance with the markingdeposited on it.

water pump

The drain pump is designed to pumping water from the tank. It consists of a small electric motor, on the shaft of which the impeller is fixed. A snail with branch pipes is put on the area of the impeller, and a drain hose is connected to it.

Breakage of the pump can be identified by the following features:

- water from the tank is not pumped out;

- a hum is heard at the bottom of the unit, but no water is pumped out;

- water is pumped out very weakly, which was not previously observed;

- other sounds are heard when the pump is working (rattle, knock, etc.).

In some cases, these symptoms may be caused by simple snail blockage, due to which the impeller cannot rotate. But sometimes the impeller breaks, or the shaft is bent, holding it. In this case, you will need washing machine pump replacementwhich is easy to make yourself.

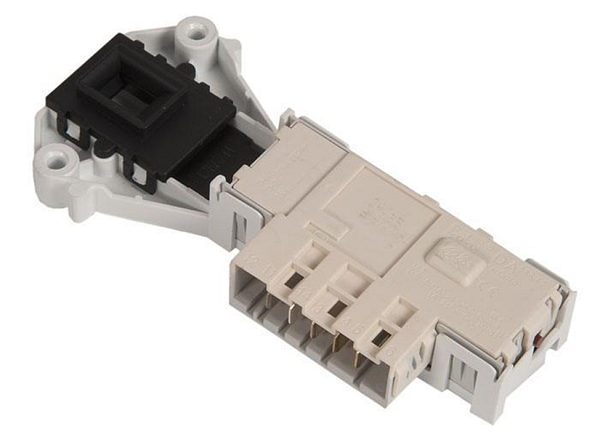

Hatch lock

Is an protective door mechanism a washing machine that prevents inadvertent opening of it in the process of washing. Also, the washing process cannot start while the hatch is open. Work will continue only after the lock receives a signal to the control board that the door is closed.

If a blocker breaks down, the following symptoms occur.

- When closing the door, the washing process does not start. At the same time, on the display of some units, an error code can be displayed, which can be interpreted as a “poorly closed hatch”.

- After the end of the washing program, the hatch remains locked and does not open.

To make sure that these problems occurred due to the blocker, it is necessary diagnose with a tester. If it is confirmed that the lock is defective, it should be replaced.

Filters

Usually in modern washing machines there are 2 filters: one at the inlet, in front of the inlet hose, and the other at the outlet, before the drain pump. Each filter will perform its functions as follows:

- the intake filter ensures the purification of water entering the machine from mechanical impurities (rust, sand, scale, etc.);

- an exhaust filter protects the pump from small items getting into it from the tank (pins, pins, buttons, threads, slagged powder residues, etc.).

If the filter installed at the entrance to the apparatus becomes clogged, water will accumulate very slowly, and sometimes, if the net becomes very clogged, it will no longer flow into the tank at all. If the exhaust filter is clogged, there may be more symptoms:

- the machine stops draining the water, while the pump is heard;

- in the mode of draining and pressing water drains very slowly;

- an error code corresponding to this fault appears on the display;

- the machine does not switch to rinsing mode.

To get rid of the above problems, you will need clean the washing machine filters.

Hoses

2 hoses are connected to the washing machine: jellied and drain. Hoses differ in appearance and design:

- the inlet hose is more designed for the high pressure of water present in the water supply system and is used to supply fluid to the tank;

- drain hose has a larger diameter than the drain, and is used to drain water from the tank unit.

Basically, the hoses fail due to damage to their shell or due to breakage of the fastening nut, which is made of plastic. If the hose is defective, then there will be a flood in the house.

To eliminate these problems, you must first properly operate the water supply hose. But if any faults occur in any of the hoses, then the part with the defect must be replaced. It is very important to properly connect the hoses to the washing machine.

Of course, in case of serious damage to the washing machine, it is better to invite a specialist. But not everyone guesses that most of the faults of household appliances can eliminate by yourself and at the same time save a significant amount that would have to pay after the repair. After all, it includes the cost of calling the master, the cost of the work carried out, the inflated price of the replaced part.If you decide to conduct self-repair of a washing machine, then all the details for this purpose can be purchased by visiting the spare parts store.

/rating_off.png)