How is your washing machine

Almost every house has washing machine (SMA). But how it can be arranged remains a mystery to most people. If you are going to repair some components of your washing machine yourself, then it will be useful to know how the washing machine is arranged.

Content

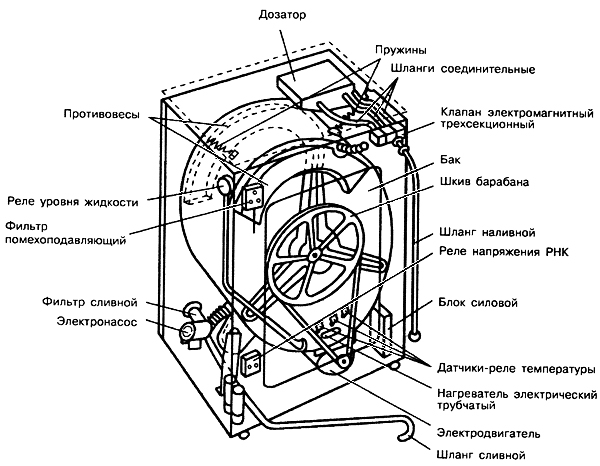

Washing machine circuit

Before you consider each node of the CMA, you should see how the washing machine diagram looks, so that you have a general idea of its structure.

Control module

This part of the washing machine can be called, without exaggeration, the “brain” of the device. He controls all the processes when the unit starts to erase, gives commands to all nodes, including the electric motor, to start or end work. AT control module are set special programswhich he performs. The list of these programs for each model of the SMA is different. There are more “smart” modules, with a large list of modes and tasks. There are easier, giving commands to perform the basic functions of washing and spinning.

When the electronics fails, the SMA starts working with errors, or stops altogether.

To control the washing process, the module needs information from different parts of the machine. For this purpose, sensors are used that send signals to the “brain” of the washer:

- water level control sensor (pressure switch);

- thermostat;

- tachometer;

- other electronics.

Water level sensor

This sensor monitors the water level in the tank. With it, the module learns information about its quantity during filling. Together with this sensor works air chamberwhich, depending on how full the tank is, applies pressure to it.

Thermostat

This meter is located at the very bottom of the tank, and is partially embedded in it.It measures the temperature indicators of water and sends a signal to the control module.

Tachometer

To control the speed of rotation of the engine used tachometer. Only with its help are possible different speeds engine in the process of washing or spinning.

Other electronics

It includes a variety of relays (for example, a sunroof closing sensor), indicator lights and a display showing information about the performance of the current operation, navigation bar. So, in models of cars ATLANT (Atlas), there are five types of panels:

- with LED indication;

- with segment display and light indication;

- control panel with LCD display;

- control panel with LCD display and navigation buttons;

- with LED display and segment display.

Elements of AGR

As a result of receiving all the information from the sensors, the electronic module begins to process it and gives a command to the control elements of the machine, after which the whole mechanism is activated. These include:

- Castleclosing the hatch door;

- water supply valve;

- electric motor;

- TEN - tubular electric heater;

- water pump;

Hatch door lock

On the front wall of the machine there is a door through which the laundry is loaded.In some models of washing machines, such as Ariston, it has increased diameterthat facilitates loading. When the wash starts, the incoming signal to the hatch lock locks it until the program runs to the end.

Water supply valve

After locking the hatch door, the “brain” sends a signal to the inlet valve to open it and start to pick up water. It will be recruited until a signal is received from the pressostat that the filling of the tank is already sufficient.

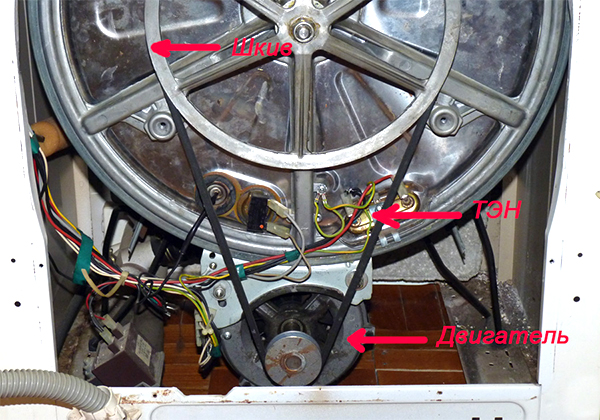

Electric motor

To set the drum in motion, the engine is commanded to start. It is connected to the drum by belt drive through the pulley.

AT direct drive cars these elements are not. The drum is a rotor rotating in a magnetic field of the stator (coil).

The direction and speed of rotation are set by a wired program through an electronic control system.

Tubular Heater

To heat the water in the tank, is used TEN. The voltage is applied to it after a command from the control system, after which it begins water heating to the required indicators. When the programmed temperature is reached, the thermostat sends a signal to the module to turn off the heat.

It should be noted that the heating elements over time is covered with a thick layer scum, which worsens the return of heat, which results in overheating and burn-in of the heater coil. Therefore, it is recommended to periodically conduct TENA cleaning. But, for example, in the new Samsung washing machines (Samsung) a heater is used that has a double ceramic coating.

water pump

After completion of the washing program, the command to turn on the drain pump (pump) is received. The pump electric motor starts up, and the pumping of water begins through the drain hose to the sewer system.

The same action takes place when the rinsing algorithm is executed. The pump consists on the one hand of a snail containing filterand on the other hand, an electric motor with a cross impeller. Filter available through the front panel of the housing for regular cleaning. If not cleaned, the pump may fail.

Bak SMA

Washer tank is the largest element of this device. The concept of the washing machine clearly shows that it occupies almost all the internal space of the unit. In the tank there is a drum into which the laundry is loaded.The tank is a plastic container with a drum, a tubular electric heater (heater) and a thermostat inside.

In CMA ATLANT (Atlant) it is made of high quality polypropylene.

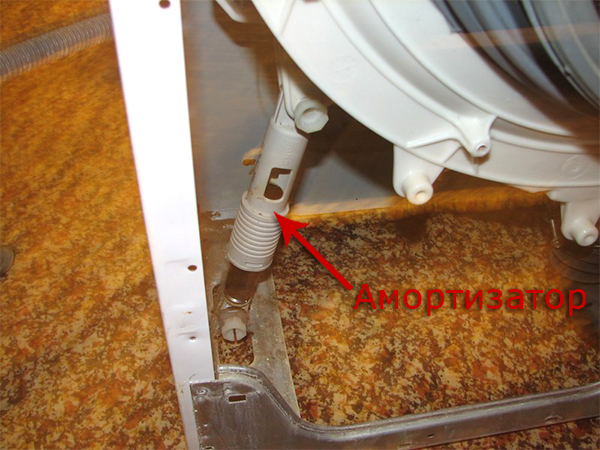

For convenience of repair, the tank is divided into two parts, which can be connected, depending on the model of the machine, by bolts or brackets. On the tank there are attachment points for nozzles. Through them is pouring and draining water. Due to the large weight of this design, the top of the drum is fixed through the springs to the body, and the bottom is mounted on shock absorbersthat soften the vibration.

Drum

The drum housing is made of stainless steel, the walls are perforated for good penetration of water from the tank during the washing process. The linen during rotational movements of the drum turns over and thus is erased.

For tightness, the front of the drum is connected to the tank through rubber cuff. On the back side, it has a shaft that goes out through the back wall of the tank. Bearing and oil seal are mounted on the shaft. In Ardo washing machines vertically loadedThe design of the drum is slightly different. On its side are the doors, through them the laundry is loaded.

Other housing parts

The main part of the design of an automatic washing machine has been described above. But there were some elements that were not mentioned:

- powder bin;

- counterweights;

- washing machine housing;

- hoses.

Powder bin

In the dispenser compartment there is a tray for powder and rinse aid. This department summed up nipplesthrough which water is supplied to flush detergents.

The device of the washing machine automatic Zanussi (Zanussi) differs from other models by the presence jet system systemswhich due to the constant circulation of the washing solution evenly soaks the laundry during the soaking. The unit is able to determine the moment when the fabric is well soaked, and it's time to turn off the water supply.

Counterbalances

In order to balance the resulting vibration during the spinning of laundry, a counterbalance system is installed in the body of the machine. In appearance, they represent concrete blockswhich are mounted at the top and bottom of the tank.

SMA building

If all internal parts are removed from the machine, then there will be a body containing a loading hatch and the top cover. The body is the frame of the machine, to which all elements and components of the washing unit are attached.

Hoses

To fill or discharge water from the machine, hoses are connected to it. Drain divert to the sewer or in a special container. Bulk connects one end to the water supply, and the other to the MCA.

The principle of operation of the washing machine machine was discussed above. And having understood how this unit works, you can begin to study its individual parts and mechanisms. But there are SMA with a vertical load, for example - Ardo. The design of such washing machines is characterized by the placement of the loading hatch, and some internal design features developed for this type of unit.

A brief overview of the SMA nodes, of course, will not help you with the repair, but knowing the device, it is easier to find the cause machine faults and examine the node, failed more thoroughly.

/rating_off.png)