Making a boiler indirect heating with their own hands

The problem with hot water for many private property owners, where there is no connection to the central heating system, remains relevant today. Installing a boiler requires serious investment, but making a boiler for indirect heating with your own hands can be an alternative to solving this important issue. Its main benefit is that hot water is supplied as needed at no extra cost in monetary terms from you.

Content

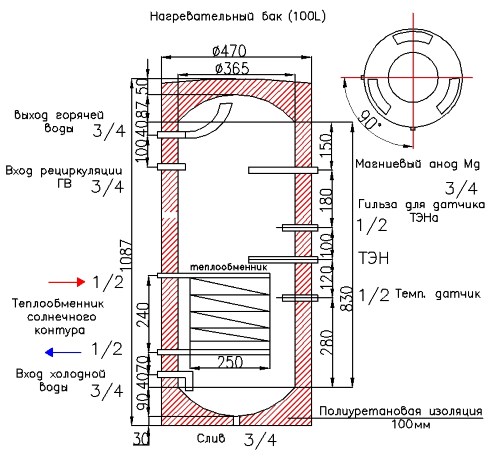

Boiler design

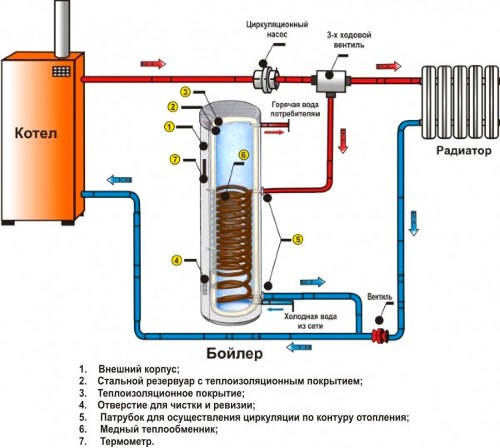

Many private homeowners are interested in the question: what kind of device is it, how does the water heat up in it?This type of product is large. cumulative design, independent of standard energy sources (gas, electrical system), in simple terms, a water heater of a circulation type.

Inside the tank is installed spiral pipe - it is in it that the water heated by the boiler for independent heating circulates. Cold water enters through the pipe located at the bottom, it is evenly heated in the tank and is supplied to the user through the output pipeline, which is located at the top. For maximum convenience, the pipes are connected Ball Valves. Outside the tank is closed with a thick layer of insulation.

The drawings of this product are very simple and easy to read, if you have at least the basics of technical education.

Varieties of systems

Those users who use geysers and various types of boilers to get hot water are very familiar with a lot of problems arising during their operation: you have to wait some time until the water heats up to the right temperature if you turn on hot water in the kitchen and bathroom at the same time, then her temperature will drop. The indirect boiler eliminates these problems: the water coming from it always has a constanttemperature, no matter where it is supplied. Such water heaters can be of several types.

- The most common is the coil design, which is installed inside the tankand hot water circulates through it. Cold water, entering the tank, is in contact with the coil and is heated to the set temperature.

- Another option is when the coil is mounted along the tank wallsand not in its center.

- If there are two containers - large and small, then the smaller ones are inserted into the larger ones. Water circulates between them: hot water is pumped into a small one, and around it is cold water for heating.

The principle of operation of such water heaters is simple, in order to clearly understand the operation of the system there is a detailed scheme.

The advantages and disadvantages of indirect heating boiler

Advantages of an indirect heating boiler designed by yourself over other water heaters:

- ability to connect to centralized heating system;

- the main tank is installed in the immediate vicinity of the boiler autonomous heating;

- installation of the whole structure does not take much time;

- electricity and gas consumption is reduced;

- the house is provided with hot water of the same temperature all the time.

There are not so many disadvantages to this design:

- for installation you will need special room;

- it takes a long time to heat the water in the tank to the optimum temperature when it is first started, and this guarantees losses in the general heating of all other rooms;

- it is necessary to clean the coil at least twice in 12 months so that it does not clog up with sediments.

Important! This option is valid only during the autumn-winter season, after it ends, the built-in heater is activated. Owners of private buildings that use independent heating can cut off the flow of water to heat the house, and continue to heat the water in the tank with a boiler.

If you use electric heating elements, it is better to turn them on at night, during the period of the benefits.

Types of work and materials

To make a boiler yourself, you need to do the following work:

- prepare a metal container with good anti-corrosion characteristics;

- gently bend the pipe for the coil;

- make high-quality thermal insulation of the structure;

- complete assembly of the entire system;

- bring water;

- coil securely connected to the domestic heating system;

- connect the heated water supply to the home plumbing.

To perform some operations, you will need the following materials and equipment:

- metal or plastic pipes;

- nitro-enamel primer;

- nut with a diameter of about 32 mm;

- large capacity - a simple gas cylinder will fit for a small family;

- need welding.

With all the materials and the upcoming types of work, we have decided, now proceed to the direct installation.

Assembly technology

We will write out in stages how to make an indirect heating boiler with your own hands - the whole complex of works will consist of the sequential assembly of different parts of the structure.

Water heater tank

The volume of the tank, where water will be supplied for subsequent heating, depends on the needs of the homeowner: the standard consumption is up to 70 liters per household per day, so 200 liters will be enough for a family of 4 people.

The material of the tank should be chosen from an alloy of aluminum, as well as other non-ferrous metals that are not subject to corrosion, if finances allow - stainless steel. A good alternative is gas cylinder, but the inner walls should be treated with a special primer, otherwise hot water will have an unpleasant rotten smell.

At least 5 holes should be cut into the body of the tank with your own hands: two from any side - they are intended for inserting a coil, at the bottom also 2 - for supplying water and a drain valve, at the top only one - withdrawing hot water.

Making a coil

This item made from copper pipe small diameter, but thick-walled, may necessarily have different dimensions - it depends on the volume and height of the container. Experts say that for every 10 liters. water requires 1.5 kW of thermal power coil.

You can use pipes from another material to save money from your home budget, but always with excellent heat dissipation. In the manufacture it is necessary to carefully monitor the formation of coils:

- they do not touch at all - there should be a gap between the coils;

- it is impossible to make excessive efforts - it will greatly complicate the removal of the finished product from a special mandrel;

- the number of turns is strictly calculated and depends on the dimensions of the tank.

For the mandrel use a pipe of the required diameter or a round wooden log without knots.After making the spiral carefully cover protective heat-resistant varnish.

We warm a design

The tank on the outside is necessarily covered with insulation to reduce losses and increase product efficiency - this can be special foam for installation or other material with excellent thermal insulation properties, such as foam.

It is attached with wire, special ties or put on glue. From the top of the insulation masters recommend reinforcing foil sheets or use insulation with one foil side. Some craftsmen for insulation insert a boiler into a larger tank, and the space between it and the inner walls is filled with insulation of any kind.

Final assembly

When all the details of the future design are prepared, then its assembly begins.

- The coil is installed in the center or along the inner surface of the tank, the nozzles are attached to the ends (soldering or welding).

- In the vertical position, the legs are welded to the container; in the wall arrangement, special fastening loops.

- A heating element is welded to the bottom of the tank.

- A lid is installed on top and welded to the body.

- The coil is connected to the circuit of the autonomous system according to the chosen scheme.

- Connect the cold water supply pipes and the hot water outlet.

- We connect the water heater to the home water system.

For consultation, so that there are fewer questions, we recommend watching this video:

Then you just have to enjoy the abundance of hot water without significant financial investments.

Low cost production

Experts offer the original version of the production of a similar type of water heater, but for this you need the following components:

- copper or bronze tube;

- boards of different sizes;

- sheet aluminum;

- a collector made of copper or its alloy;

- specific format glass sheets;

- special paint composition.

We make the hull of the required size of the body, inside we sheathe it with aluminum sheet. Along the perimeter we install pipes like a coil, we attach a collector to them, taking into account which side will be the inlet and where is the outlet.

Such a system is quite simple and functional - with its help you will heat the right amount of water, and the manufacturing technology is similar to the standard version.

To make the construction absorb heat better and not give it away, glass and special paint are used.

In the manufacture of such a water heater turns enviable saving money - you just have to choose a suitable option for your premises and begin work.

/rating_off.png)