What can be done from a chainsaw with your own hands

The petrol saw is a good helper when harvesting firewood, cutting down trees, caring for a garden, and cleaning an overgrown plot. Its basis is the internal combustion engine, which is characterized by compact size, reliability, low weight, good power performance. Such advantages of the drive allow you to create various original homemade tools from a chainsaw: walker, grinder, snowplow, lawn mower, sawmill, electric generator, go-kart, snowmobile. The motor is also installed on the bike, boat, making these vehicles more practical. At the same time, craftsmen often use not only the engine, but also other parts from the unit. The difficulty in reworking lies in the exact fit to the size of the parts collected equipment.

Content

- 1 Outboard motor on the basis of the engine from a gasoline saw

- 2 Sawmill assembly

- 3 Homemade bike with a motor

- 4 Homemade Lawn Mower

- 5 Making a snowmobile

- 6 Creating a trimmer

- 7 Snow blower with gasoline engine

- 8 Manufacture of grinders

- 9 Build karting and buggy machines

- 10 The generator of electrical energy from the internal combustion engine from a chainsaw

- 11 Motoblock for home use

- 12 Agricultural cultivator do it yourself

- 13 Petrol saw

Outboard motor on the basis of the engine from a gasoline saw

To make the outboard motor of a chainsaw is not difficult. Tinkering is done as follows:

- remove the tire from the saw;

- instead of it, using a special adapter, attach a self-propelled or factory-made boat screw to the motor;

- then the whole structure is fixed on the boat so that the propeller is immersed in water at an angle.

Instead of an adapter, some craftsmen install gear. The possible result of the work is shown in the photo below.

For lovers of fishing, home-made boat motor is an economical option that allows you to significantly speed up movement on the water surface of lakes, rivers, ponds.

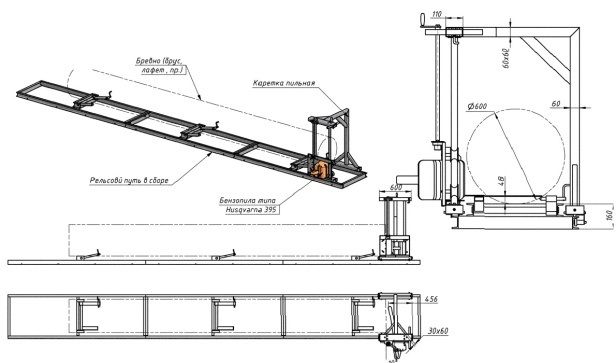

Sawmill assembly

When building houses and other buildings of logs often have to dissolve them on the timber.A sawmill from a chainsaw allows you to do this as efficiently as possible with good cutting accuracy. At the same time, the tool itself does not require any alterations. Its just fixed in the frame made, for example, from metal corners or shaped tubes. The processed logs keep within on guides. The whole structure is shown in the diagram below.

In a homemade sawmill, the log is not moved: the carriage with a saw moves at the correct height (depending on the thickness of the lumber) with four screws.. Due to the fact that the frame is moving exactly, sawing occurs neatly, the cut is smooth. The created device (a variant of it is presented in the photo below) also allows you to saw boards and prepare firewood without any problems.

A small minus is the formation of a large number of sawdust. This is due to the considerable thickness of the chain.

Homemade bike with a motor

Craftsmen have invented a variety of options, how to convert a bicycle into a moped. Their meaning is as follows:

- the bike is taken;

- motor with a gas tank is attached to the trunk or frame;

- a gearbox (having a gear ratio of 18 to 1) and special gear is installed;

- additional shock absorbers are mounted;

- put the brake.

Instead of gearbox use two gear pairsconnecting to each other using a bicycle chain. Different old bicycles are often taken as a basis (as in the photo below), and more modern (mountain) models are used much less frequently.

Usually a bike with a motor from a chainsaw is made for the sake of entertainment: a motorbike rides at the speed of normal.

Homemade Lawn Mower

Lawnmowers is a technique for grass cleaning. They are used by owners of private houses and cottages to give land plots an attractive, well-groomed look. Factory-made models are easy to use, but at a cost they are not available to everyone. A lawn mower made from a chainsaw will be much cheaper than branded analogues. Its capacity is quite enough for domestic use.

Home craftsmen collect homemade lawn mowers of various types and capabilities. But any design provides for the presence of such elements:

- drive;

- frame;

- pens;

- wheels;

- knives;

- control systems;

- protective casing.

Manufacturing process lawn mowers are held in the following sequence:

- weld the frame of a suitable size, for example, from metal angles 25 to 25 mm;

- using bolts or welding, handles of iron tubes are attached to the frame;

- mounted on the corners of the frame wheels;

- remove the handle and the tire from a petrol saw;

- screw the remaining part of the tool to the frame with the help of studs and nuts so that the shaft of the gearbox turned upside down by 90 degrees is directed downwards;

- extend the gas cable;

- A telescopic shaft is made of two metal tubes, which is then attached to the gearbox;

- make a knife on their own (for example, from a hand saw blade) or purchase a factory product;

- using bolts or welding, connect it to the shaft.

Will fit baby stroller wheelsfrom the old car. If you use pipes of different diameters, you can make a telescopic handle with the ability to adjust its length - this increases the convenience of operation.

Knives There are different designs. Their simplest version is presented in the following photo.

The presence of a telescopic shaft will allow you to adjust the height of the grass cover left after the mowing.

Knives made of quality steel are not afraid to meet with small stones.They are able to mow even thin bushes. Self-made mower is additionally equipped with some craftsmen collector, thanks to which there is practically no cut grass at the site.

Making a snowmobile

Home craftsmen managed to make a snowmobile from a chainsaw. The machine consists of the following structural elements:

- frames;

- internal combustion engine (ICE) with a power of about 5 hp;

- suspension with shock absorber;

- steering wheel;

- passenger seat;

- skis or tracks;

- control systems (clutch, gas).

Own production snowmobile can be equipped optionally skiing or tracks. If you put the skis, you get snowmobiles, which will be similar to the sample of equipment presented in the photo below. The movement of such a machine will be carried out by rotating the screw. Snowmobiles are easier to make than snowmobiles.

When selecting tracks, an important point is the organization of a thoughtful node transmitting torque to them from the engine. On the created snowmobile, the possible appearance of which is shown in the photo below, you will need to install a centrifugal clutch with a chain and a belt.To increase the drive capacity of the drive, it is recommended to equip the caterpillar shaft with gears of a larger diameter than the engine.

As steering wheel This item is suitable from a bicycle or from a scooter. You can also make it from metal tubes.

The more powerful the installed engine will be, the greater the cross-country ability of the assembled snowmobile will be.

Creating a trimmer

A trimmer, like a lawnmower, is used to mow grass on a plot. But the motokine is used for relatively smaller amounts of work or on rough terrain, stony ground. A trimmer made from a chainsaw, made by yourself, will be much cheaper than its factory counterpart. The performance of this unit is quite high.

The simplest option for creating mowers is to use a special factory nozzles for gasoline saw, work with which is shown in the following video.

Snow blower with gasoline engine

In order not to scatter snow with a shovel in winter, it is quite possible to make a snow blower from a chainsaw. For the practical implementation of the project is necessary motor about 3 kW (4.1 hp), for example, from the saw "Calm". In addition to the drive, the snow blower consists of the following components and parts:

- intake compartment with a screw with blades located inside;

- pens;

- frames;

- snow ejector.

All these nodes are visible in the following photo.

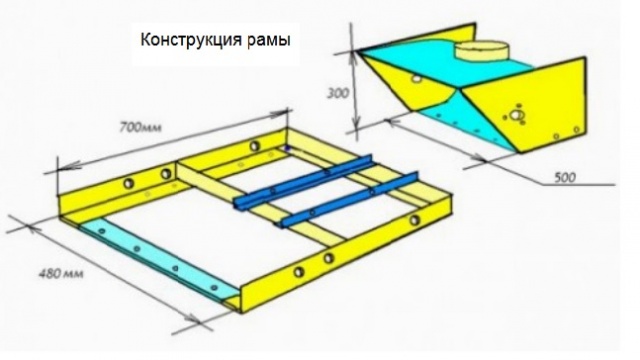

The craftsmen presented the wheel and snowplow models equipped with a sled runners. The latter option is simpler in a constructive way for implementation. The design of the frame and intake compartment is shown in the photo below.

The main points are the selection of a pair of gears and the manufacture of a good auger (shown in the photo below), which will be driven through a chain drive by a motor.

For the manufacture of intake housing suitable galvanized steel sheets. Auger blades are often made of thick rubber. A plastic sewer pipe is quite suitable as a snow ejector.

Manufacture of grinders

Angle grinder - a multifunctional tool that is necessary when carrying out a variety of work. Despite its availability and prevalence, the craftsmen made a Bulgarian from a chainsaw (the sample is shown in the photo below).

The disk of such self-made equipment will not rotate by an electric motor, but by an internal combustion engine from a saw.

Assembly Bulgarian with the use of special tools for chainsaw is as follows:

- the chain and tire are removed from the gasoline saw;

- set on the gear shaft pulley;

- instead of a tire, they mount a special nozzle with a pulley too, having previously put a belt on it;

- tension the belt transmission as a chain;

- attach the protective cover;

- put the disk.

The whole process is shown in detail in the video below.

Self-assembled Bulgarian-Benzorez will help in performing many practical tasks. Its capacity is sufficient for productive work on concrete.

Build karting and buggy machines

Carting - This is a race on small cars (maps), without a body, elastic suspension at the wheels. This machine is designed to ride on a flat asphalt surface, where it is able to reach a sufficiently high speed.

At home, it is quite possible to assemble a kart from a chainsaw and such parts:

- wheels;

- steering unit;

- frame;

- brake and control systems.

The following video contains a detailed overview of the possible options for homemade karting.

Cards with the engine from a petrol saw are relatively inexpensive. For children, it will become a fascinating pastime.

Buggy constructively and to destination similar to the map, but they have a suspension. This feature allows you to more conveniently go on rough terrain (off road).

Self-assembly of the buggy is similar to making a map (except for the suspension) and is performed in the following sequence:

- weld frame;

- make a suspension, for example, of the torsion type;

- make steering parts;

- collect suspension;

- mounted steering wheel and thrust;

- attach wheels;

- put the brake;

- set the chair;

- fix the engine.

A chain or belt is used to transmit the rotation from the motor to the wheel. Accordingly, asterisks or pulleys are installed. That the car worked more silently, will improve existing gasoline silencer either make a new one. There are options for homemade cars that can reach speeds of over 40 km / h, so you need to drive carefully to avoid an accident.

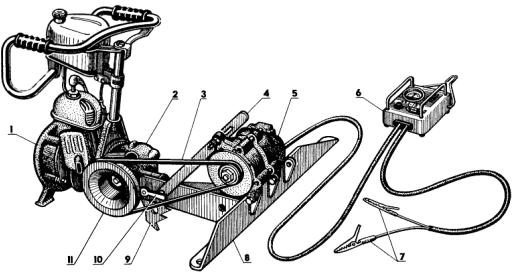

The generator of electrical energy from the internal combustion engine from a chainsaw

Most modern appliances are powered by electrical energy. Away from power lines, it is mainly obtained from electric generators. Such portable equipment with batteries is used and in field conditions. To save money, you can independently make a generator of chainsaws. Schematically, its construction is presented below.

In the photo above, the following structural elements of a portable electric generator correspond to the numbers:

- gasoline saw;

- gear reducer;

- drive belt;

- level for tension;

- electric generator;

- Control Panel;

- clamps;

- emphasis saws;

- fastening nut (designed to be attached to the gearbox frame);

- driving pulley

Self-made mini-power plants equip ac or dc electric generators (for example, from a car on 12-14 V). The output voltage and its other current characteristics depend on it.

Motoblock for home use

Motoblock is an agricultural machinery, which, thanks to the possibility of installing various attachments, is capable of plowing and cultivating the soil, making furrows, and also performing other operations.Essentially, powerful models are mini tractors. Manufactured machinery is expensive, it will be cheaper to cost the walker from a hand-made chainsaw.

Assembly of the unit is not difficult. The device is a homemade motoblock shown in the video below.

There are a lot of constructive versions of the motoblocks made by craftsmen. You should choose the most suitable option for the available components and functionality.

Agricultural cultivator do it yourself

A cultivator is a technique designed to loosen the soil layer and cut the roots of weeds in it. The working body of the unit is rotating mill. Due to its rotation, the cultivator moves along the treated area.

According to its power, the motor-cultivator is inferior to the motor-block. For the latter there is a special cultivating nozzle.

Cultivator from the chainsaw own assembly is quite suitable for processing a small area. A variant of the construction of such an improvised equipment is considered in the following video.

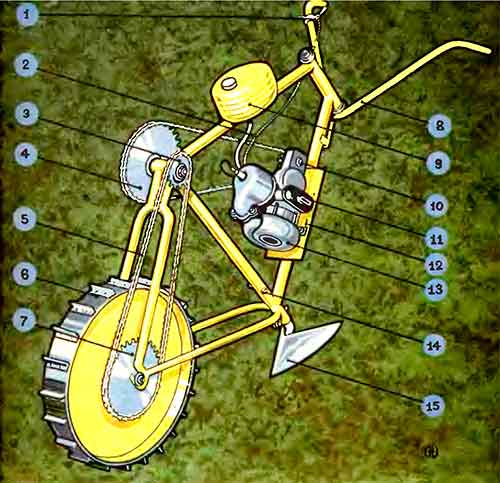

Petrol saw

Hiller is a highly specialized technique that is used to hilling potatoes. At the same time, weeds are removed between the rows.

Collect okuchnik from chainsaws easy. Its construction is shown in the diagram below.

The following design elements correspond to the digital designation on the diagram:

- 1 - motor control handle;

- 2 - cable;

- 3.4, 7, 10 - asterisks of the gears;

- 5 - chain;

- 6 - wheel;

- 8 - the handle;

- 9 - fuel tank;

- 11 - motor mount;

- 12 - platform for the engine;

- 13 - internal combustion engine;

- 14 - frame;

- 15 - plow (hiller attachment).

The work of the homemade hiller is shown later in the video.

In addition to the options considered, taking the drive from the gasoline saw as a basis, you can do an ATV, mini-helicopter, winch, pit hole or ice drill with your own hands.. For most home-made, an engine with a power of 2-3 kW (approximately 2.7-4.1 hp), for example, from chains “Shtil”, “Friendship”, “Ural”, is suitable. But for the helicopter you will need a motor with a large given parameter. In order to find out the required specific amount of power, it will be necessary in this case to carry out accurate engineering calculations.

For reworking, it is recommended to use an old inexpensive tool, so that in the event of a quick breakdown of the created mechanism, it will not incur any special financial losses.It is better to use models that are easy to understand, and finding parts on them when replacement is necessary is easy. During assembly, parts should be carefully joined, making sure that they dock without problems. Pre-created drawings will facilitate and speed up the process. In any case, a homemade unit should be safe.

/rating_on.png)

/rating_off.png)