How to work sandblaster

Today, even people who have nothing to do with industrial activity face the concept of sandblasting. Equipment of this type is capable of solving a wide range of tasks. For example, ordering a new wardrobe, you can hear from the master the phrase that the drawings on the mirror will be made by sandblaster. For performance of these or those works it is packed in different ways, has various dimensions, the price. However, the overall structure of the sandblaster remains unchanged.

Content

The device and the principle of sandblasting

The principle of operation of any sanding installation is enclosed in a shock effect on the surface being treated with abrasive particles. Depending on the working mixture used, the mechanical force generated can vary from extremely weak to intense shock.

There are various categories of sandblasting equipment. It may be classification:

- abrasive flow: flame, air or liquid;

- depending on the abrasive with which sand blasting works (plastic granules, glass balls, steel shot, powder abrasives and much more);

- engineering solution: ejector and pressure.

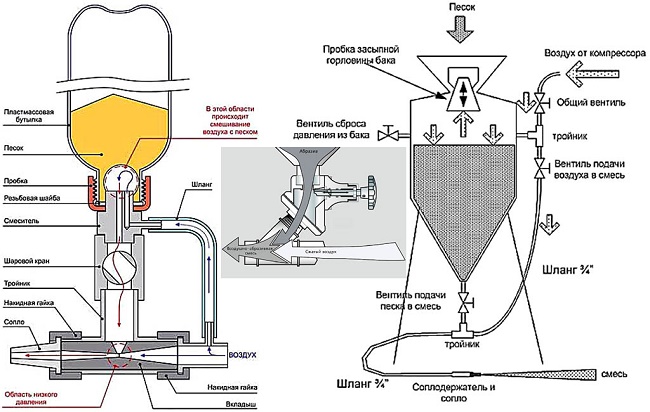

In general, the construction scheme of the sandblaster is quite simple. It contains a flow generator (air, liquid, combustible agent), a container with a working mixture, an exhaust pipe and a pistol, an operator’s tool. In the role additional equipment Receiver, automation of control and regulation, emergency response mechanics, connecting and supply cables. However, depending on the specific engineering solution, the main principles of construction of the structure may differ from each other.

Pressure head installation

Pressure sand blasting is the most simple. It is based on a container with an abrasive. Under air pressure (for simplicity, only such units will be considered):

- the abrasive in the storage bin is mixed and fed into the receiving chamber in a uniformly dispersed state;

- the working mixture is captured by the air flow and flows through the outlet hose to the gun.

The design of the pressure installation is simple. It provides not only reliability and fault tolerance of equipment, but also high performance combined with a wide range of abrasives available for use.

Ejector installation

In an ejector installation, the capture of an abrasive mixture occurs as a result of the formation of a low pressure in the intake area. The scheme works as follows:

- compressed air flows directly into the gun;

- the design of the type of nebulizer due to the Bernoulli effect forms a low pressure in the intake tube;

- the abrasive mixture in the area of the air intake tube into the container is sucked into the outlet hose and enters the gun.

Important! Ejector installation, in comparison with pressure, is characterized by lower productivity.However, it is more compact (with equal performance indicators), allows for fine work.

The characteristics of the output hose and gun nozzle play an important role in the parametric of the surface treatment process. This statement is true for any type of equipment. By increasing the diameter of the hose, you can apply a larger amount of the working mixture. For its transmission will require a nozzle of significant diameter. However, this will reduce the speed of the particles and, consequently, the speed and intensity of processing the target surface. Therefore, in practice, it is necessary to carefully balance the ratio of the diameter of the nozzle and the supply hose for optimal results.

Naturally sandblasting installations differ in weight and size and performance. For example, low-power compact and used in small workshops. For the transport of medium-sized used wheeled transport, such sand blasting will be required for processing the walls of buildings or steel structures. The most powerful class of equipment is usually applied stationary, for several operators in an industrial environment.

General safety rules when working sandblasting

Sandblasting should be carried out in compliance with all safety rules. The operator in the area of action is inevitably at risk. Main concluded in fine dust in the air, silicon when working with sand, other when using other abrasives. In addition to the residues formed by the destruction of the mixture used, inevitably the smallest particles of the coating to be destroyed enter the air. It can be the most diverse set of substances, ranging from dross, to toxic agents of paints and varnishes.

It is necessary to work with sandblasting with the obligatory observance of the basic safety rules.

- The operator is required to use special protective suit with respiratory mask, reliably isolating a person from the environment.

- Sandblaster operation is allowed only for persons reached 18 years of age.

- In cases where cleaning is performed in closed chambers, operators engaged in the task use hose gas masks. It is allowed to use closed masks with air supply outside the working room.Also, for protection, operators can use space suits with an air filtration system from oil vapors and dust.

- Enclosed rooms for working with sandblaster equipment must be equipped forced ventilation systems.

- When working at height when cleaning the walls of buildings use of safety equipment is required.

Important! Before starting work, the operator carefully checks the condition of the hoses, the grounding of the sandblaster to neutralize static voltage, inspects the power wires and assesses the condition of the injection unit.

The employee must pass safety training. For sandblasting machines, the field of knowledge includes not only information on the procedure for performing work with the apparatus in various conditions. Plant operators are required to be familiar with safety regulations when working with high pressure cylinders. In industrial conditions, the company conducts quarterly re-briefing of personnel on labor protection. Also organized annual inspection of buildings safety equipment when working with sandblasting equipment. A medical examination for busy personnel is carried out once a year.

Bodywork for metal using sandblaster

The equipment for sandblasting is widely used at service stations and in workshops engaged in painting and body repair. However, installations for carrying out such work must meet a number of criteria:

- use a wide range of abrasives for a particular impact on coatings;

- provide processing without metal damage;

- be able to adjust the speed and performance of work.

In practice, today both ordinary sand in the role of abrasive material and special mixtures are used. Rising popularity show special granuleswhich contain soda and additives. After metal treatment with such means, it is not only cleared of paint, but also receives protection against corrosion.

Important! The use of any abrasive causes the release of dust dangerous for breathing. In a small workshop room this can be a problem. Therefore, today for the treatment of the car body they use blasting devices that use carbon dioxide snow as an abrasive.

The operation of such devices is distinguished not only by careful cleaning of wheels or body parts, but also by low cost.The source of the working mixture and simultaneously the flow generator in installations of this class is liquid acid bottle. Carbon dioxide blasting is called dustless cleaning. For example, sandblasting disks can be processed in a small workshop, provided that forced ventilation is provided to remove the gas.

Sanding wood sandblasting

Wood - the material is rather fragile. Even with a long service life, the surface of the log or board collapses. Formed local areas of decay, stratification, drying. A house made of log or decorated with wooden elements begins to look unattractive. The same can be said about a variety of products from popular natural material.

To restore the original appearance of the walls or parts allows the treatment of wood sandblasting installation. Wherein:

- just a huge amount of dust;

- Work differs in the increased noise;

- there is a large amount of garbage.

Abrasive cleaning of the wood surface can be carried out:

- for restoration (restoration) of the material surface, removal of traces of rotting, drying, color change;

- for preparation of a tree for drawing antiseptics or paints and varnishes.

We should also consider such woodwork as sandblasting, as blanching. This is an operation, as a result of which the material is artificially aged, the appearance of coarse processing is formed, the texture appears. When working in art workshops to protect against the emission of a large amount of dust, blanching is performed in small sealed chambers equipped with ventilation units.

In the course of sandblasting wood, rather soft abrasives with a high content of soda are used. In this way, high environmental safety of the treated surface is achieved. In addition, soda does not affect the color of the tree, the texture, can be used even during restoration work after fires.

Glass sandblasting

Matting - A very popular way to process glass. Its main advantage: fingerprints are not visible on the surface of the material. When careful processing is achieved such a level of roughness that frosted glass does not collect dust and dirt.

Equipment for sandblasting glass operates according to the classical scheme. Abrasive ejected at high speed from the nozzle of the gun (or a special head in automated devices) knocks out the smallest particles from the surface of the glass. As a result, it becomes rough and acquires a lower indicator of light transmission.

Modern equipment for sandblasting glass can:

- matting large areas or local, limited areas;

- working with mirrors, removing reflective amalgam;

- create patterns on the surface of the material.

Sandblaster for glass software controlled able to create complex, multi-shadow images. This is achieved by a different number of passage heads over individual areas of the picture. Such glass matting can be made even on-site at the customer of the product.

On a note! Mobile sand blasting on the glass works on a hydraulic circuit. In the role of the carrier body of the abrasive mixture is purified water. Glass matting by this method does not form dangerous dust in the air, therefore it can be carried out in any room.

Sandblasting wall cleaning technology

Cleaning the surface of facades allows both to remove dirt and old paint, and to restore the surface or prepare it for coating with certain characteristics. Such handling class deemed dangerous. And this statement is true.

- During the cleaning of walls, fences, facades sandblasted apparatus in the air a large amount of silicon dust, dangerous to the lungs.

- Not only personnel are exposed to danger, but also all people in the area adjacent to the cleaning zone. These are passersby, residents of neighboring houses.

- Work on the facade is often associated with the danger of falling from a height.

The principle of cleaning the surface of the facade - the destruction of pollution, which produces a shock of abrasive particles, accelerated by the installation to 650 km / h or more. Each operator engaged in work with sandblasting equipment,must be instructed in safety.

To protect peoplelocated near the treatment area, apply:

- vacuum type installations that remove abrasive residues and dust from the area of impact immediately after it;

- partially open chambers in which the personnel works.

On the last measure of protection is to talk more. Partially closed camera - it is, roughly, a parallelepiped without one face. It is equipped with a ventilation system. Placing the camera in front of a separate segment of the wall and facade, the staff performs sandblasting cleaning with the use of protective measures (masks, suits, gas masks, space suits). The environment and people near the work area do not cause damage, or its impact is minimal.

As a conclusion

Do not think that sandblasting operations or processing can be carried out in any room, the first caught the eye and bought for a small amount of money by the unit. To achieve quality results, you must carefully select the right equipment.

Important! Mandatory organization of special places of work (habitable and uninhabited cells) will not harm the personal health and well-being of others.It is worth remembering: if there is not enough knowledge, skills, equipment - to perform certain operations using sandblasting, it is worth hiring professionals.

The best sandblasting machines in 2018

Device sanding AE & T T06505 19 of l.

Sand blasting machine 17 l GARWIN 8866101

N33235 Sandblasting camera 90l. AE & T T06301 table

JTC-5324 Sand blasting machine, 1/2 ″ hose, max. pressure 250PSI, volume 38l.

Sandblasting gun Fubag Sbg142 / 3

/rating_off.png)