The design and principle of operation of the chainsaw nodes

Gasoline saws are used in the construction of log cabins, logging, clearing the area from the undergrowth, replenishing the stock of firewood. They allow you to work effectively with wood. A relatively simple device chainsaw makes it a durable and reliable tool for both domestic use and for professional activities. Structurally, the product belongs to the category of machines equipped with an internal combustion engine (ICE). In many cases, this is a two-stroke single-cylinder engine. Knowledge of the device tool and the features of the functioning of its individual components need the user - this will help to properly perform maintenance and, if necessary, make their own repairs.

Content

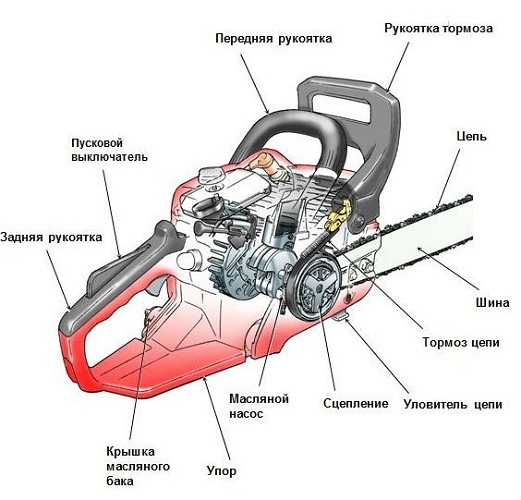

General device chainsaws

On the market there are many models of gasoline saws from different brands. Products from different manufacturers differ from each other in design and technical characteristics that determine the ergonomics and functionality of the technique, but the instrument has the same device.

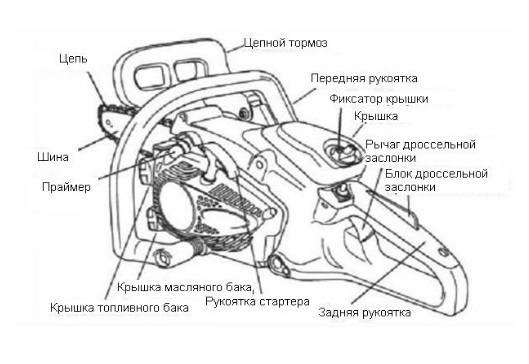

The chainsaw consists of the following structural elements:

- internal combustion engine;

- carburetor;

- tires;

- chains;

- pens;

- clutch;

- starter;

- ignition, fuel supply, air filtration and chain lubrication systems;

- muffler;

- chain brake and its tension mechanism.

The scheme of the chainsaw is shown in the photo below.

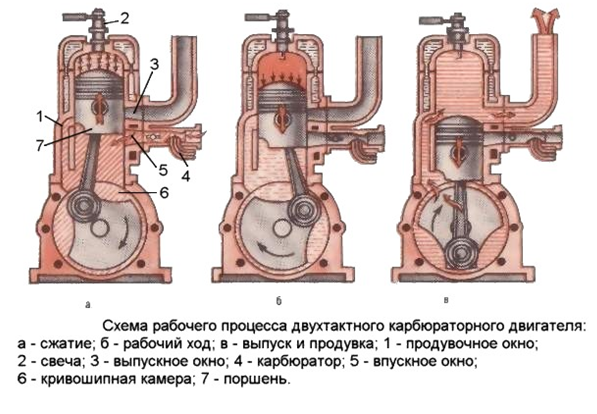

Carburetor engine works on a mixture of oil with gasoline. A diagram of his workflow is presented in the photo below.

The components of the fuel mixture is stirred in proportion. The ratios between them are indicated in the user instruction (oil to gasoline from 1:20 to 1:50, respectively). The quality of fuel depends on the duration of operation of the tool without repair.

Modern gasoline saws from the expensive category often have a tank for oil. Mixing it with gasoline in such modifications occurs automatically.

The two-stroke engine is capable of speeds of 13.5 thousand rev / min. It can be placed on the instrument. vertically or horizontally. The first version of the placement of the internal combustion engine is typical for many professional models of chainsaws of large size. They have a silencer in front of the engine.

If the motor is located horizontally, the petrol saws are compact in size. The weight of such tools is also small. These features make products with a horizontal type of motor popular with farmers, loggers and other workers using hand saws.

The design of the chainsaw requires two handles: front and rear. On the latter are placed the switch, the levers of gas and security. The tool is implemented protection against vibration and shock. The first is related to the presence of rubber pads between the handle and the saw. Some models also have springs that dampen vibrations. A special brake or flap can protect against a kickback.

The design and operation of individual nodes

The individual components of the gasoline saw, discussed above, in turn consist of various parts. To repair equipment yourself, you should know the design and operation of the main systems.

Ignition system

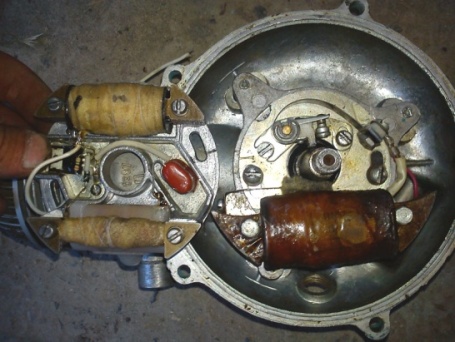

Initially, the ignition system of the chainsaw was contact type. Now it almost does not apply. Modern manufacturers equip their equipment electronic ignition (pictured further unassembled). For this reason, there is no need to regularly clean the contacts and establish the necessary distance between them.

The ignition system, due to which a spark is generated during engine start, consists of the following parts:

- magneto;

- candles;

- electronic unit;

- electrical wiring;

- buttons on / off the motor.

The appearance of the ignition system elements of one of the models of chainsaws from the brand "Shtil" is shown in the following photo.

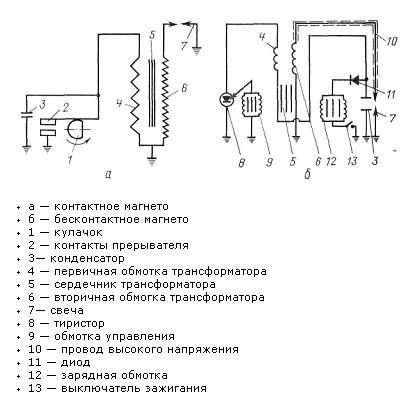

Magneto - This is an alternating current generator that supplies voltage to a candle. It can be of two types:

- contact;

- contactless.

Schematically ignition systems with contactless and contact magneto typesare presented below.

Magneto of any type includes such details:

- flywheel;

- permanent type magnet;

- coil consisting of core windings.

Part electronic unit usually included diodes, resistances of various sizes, thyristors, capacitors. Connection diagram depends on the saw model.

Ignition works on the following principle:

- during rotation of the flywheel with a permanent magnet attached to it, an electromotive force is induced in the system;

- the current in the circuit of the electronic unit converts into electrical signals;

- they are passed on to the candle;

- a spark is formed between its contacts, which causes the fuel-air mixture to ignite.

The ignition is initially adjusted so that sparking occurs when the engine piston does not reach its top dead center by about 3-4 mm. If you focus on the circumference of the crankshaft, then this corresponds to an angle of 28 degrees.

Candle consists of such parts:

- central and side electrodes;

- enclosures;

- insulator.

As the candle can be visually diagnosed malfunctioning incendiary system.

Thus, due to the presence of ignition, the fuel mixture ignites, which ensures that the motor goes into working condition. Periodically, the system needs adjustment, which is easy to carry out independently.

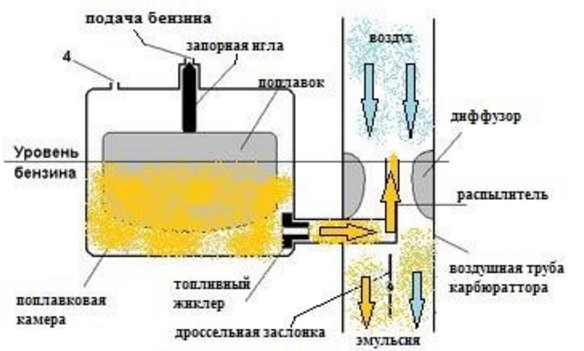

Carburetor knot

A carburetor is required for the continuous operation of the engine. It consists of the following structural elements:

- solid aluminum housing;

- jets, representing the valve, regulating the amount of fuel;

- diffuser;

- float chamber;

- spray bottle.

In the carburetor body a damper is installed, which regulates the flow of atmospheric air, pulse channel, diffuser, inlet fitting, two screws (idle and main). Very often, chainsaw manufacturers equip their products with a carburetor from common brands for sale.

Most chainsaw models are equipped with identical (by design) carburetors. Schematically, their device is shown in the photo below. Only rare cheap modifications made in China can be distinguished by the absence of a number of parts in the carburetor unit.

To properly perform adjustment of the carburetor gasoline saw, it is necessary to understand the principle of its work, which consists in the following:

- when the engine is started, the air damper located on the body in the lower part of it opens;

- due to the movement of the piston (stroke), a vacuum is created inside the float chamber, as well as in the air channel;

- this causes air to be drawn in through the diffuser;

- from the gasoline tank the fuel mixture penetrates into the float chamber, passing through the nozzle;

- then the gasoline in the diffuser is mixed with atmospheric air, this results in a fuel-air mixture;

- then it enters the intake ducts;

- from there the mixture enters the combustion chamber.

Using the valve, it is possible to enrich or deplete the fuel with air, that is, to adjust the intensity of its receipt in accordance with the working conditions. With the help of screws adjust the engine speed. The rate of gasoline entering the diffuser from the chamber is adjusted by the jet. The incoming air is cleaned by a filter mounted above the carburetor.

The operability of the carburetor unit determines the performance of the chainsaw and the performance of its motor.

Clutch mechanism

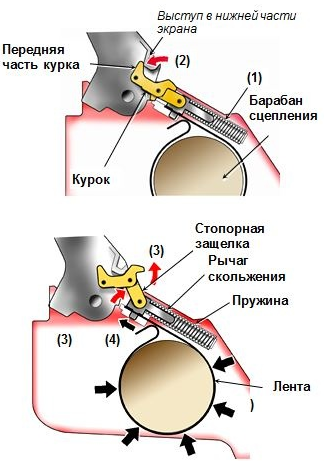

Chainsaw Coupling centrifugal type. It works automatically when the motor speed reaches the required number of revolutions.

Schematically, the centrifugal clutch operation is shown below in the photo, where the numbers correspond to the following structural elements:

- friction linings;

- springs;

- drum.

At low revs of the motor lining, which can move radially, springs are tightened to the shaft. At this time, they do not rotate the drum connected to the chain sprocket. When the internal combustion engine develops the speed at which the force from the springs becomes less than the current centrifugal force, the friction linings set the drum in motion, pressing against its inner surface. In this case, the asterisk, which moves the chain, comes into rotation. It can be located in different models of gasoline saws in front of the clutch or behind it.

The main advantage of centrifugal couplings is that they slip when the chain is jammed and the motor does not stall.

Fuel system

The device of the fuel system is shown in the diagram below.

The numbers correspond to the following elements:

- fuel filter;

- carburetor;

- fuel pump (primer) manual type.

Gasoline is in the tank, from which it enters the carburetor assembly through a hose. The simplest options do not include a pump. Fuel filter located at the end of the hose, immersed in gasoline. Its appearance is depicted in the following photo.

When fuel is consumed in the tank, negative pressure is formed due to its filling with atmospheric air. This leads to the fact that the flow of gasoline into the carburetor unit stops. To avoid this phenomenon, the tank cover equip with breather: when it is contaminated the instrument stalls.

Chainsaw primer makes starting it easy. The carburetor department is filled with fuel in advance, which allows you to quickly start the engine, and also reduces the load on it.

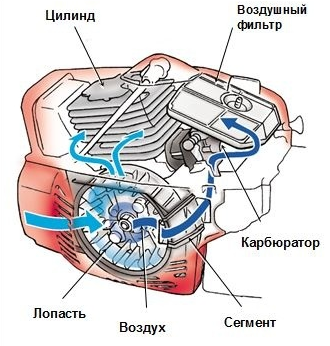

Air cleaning system

In order to get a good quality fuel-air mixture, clean gas is required. The presence of impurities in the air can disrupt the operation of the instrument engine. Therefore, chainsaws are equipped to remove contaminating particles with a filtering system of preliminary and fine cleaning.

Pre-filtering is usually done using strainer.

During operation at low temperatures, an element that retains snow is also installed. But because of it, the air supply is deteriorating, causing a drop in the power of the unit being operated.

Filters intended for fine cleaning (photo below), made from a nylon mesh or foam rubber or from materials of similar characteristics.

Some saw models have inlet air cleaning system centrifugal type. It is installed instead of the pre-filter element. The meaning of the functioning of such a cleaning is that the incoming air flow is twisted with a flywheel. In this case, contaminating particles are thrown away from the nozzle leading to the filter.

Contamination of filter elements leads to a decrease in the volume of atmospheric air entering the carburetor assembly. This causes a drop in the motor power of the saw. Because of this reason, filters that clean the air of impurities should clean regularly flushing or simple blowing. A suitable method is determined by the material from which they are made.

Starter device

The chainsaw starter is designed to start its engine, which is carried out by cranking the crankshaft. In this case, the fuel-air mixture that is in the engine is compressed by the piston. The spark causes it to ignite, causing the engine to start.

Starter components are:

- lever;

- cable;

- drum;

- return spring.

With a sharp pull of the cable handle, the drum engages with the shaft. The latter begins to scroll. After releasing the handle, the spring ensures that it returns to its original position. To rotate the shaft at such a speed at which the motor will start, you must make some effort: in most cases, you will need to pull the handle several times.

In order to make the engine starting process easier, in practice, for example, the following methods are used:

- using the valve to enrich the fuel mixture;

- using a special valve, reduce the pressure inside the cylinder.

To facilitate the launch, some starter models also provide for additional spring. It is initially compressed by pulling the cable, and then unclenched, spinning this engine.

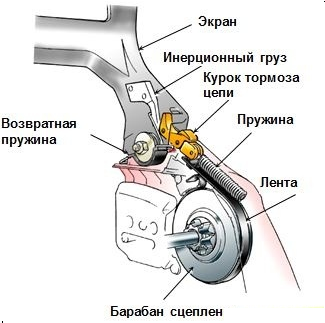

Chain brake

The chain in the gasoline saw is a traumatic factor. When it rotates, a short, gentle touch to it is enough to cut yourself or get more serious injury. For this reason, there is a chain brake on the chainsaw, which quickly stops it if back kick

According to the mode of action of the brake, there are two varieties:

- inertia, reacting to the force of inertia, which acts on the brake mechanism;

- contact, stopping the chain with the return stroke after the brake stop is pressed.

Brakes of inertial type work much faster than contact analogs.

Before using the chainsaw for safety reasons should be every time check the performance of the chain brake. If it does not work, then the tool should not be used until the fault is eliminated.

The general principle of operation of a chainsaw of any model is simple: a running engine spins the chain, which is sawn wood. The operation of the instrument depends on the state of its individual parts, the quality of the fuel mixture, the degree of purification of the incoming air.To ensure that the equipment used lasts as long as possible, it is necessary to organize ongoing maintenance, relying on the instructions contained in the operating instructions.

/rating_off.png)