Rules for replacing and stretching chains on a chainsaw

The tension of the chain on the chainsaw affects not only the normal operation of the unit, but also the safety of the operator working with it. A chainsaw is a very traumatic tool, and a loose saw chain can lead to dire consequences. In turn, an excessively stretched chain increases the load on the tool. Therefore, before each launch of the device, it is necessary to make sure that this important element has the correct tension.

Content

How to determine the degree of tension

A quick check of the chain tension is very simple: you need to grab the barb and pull it up. If the chain is tensioned correctly, the tail will be immersed in the groove of the tire at 1/3 of its height. The excess of this indicator indicates excessive tension, and a decrease in the indicator indicates a weak one.

Normally, the saw should move freely along the tire, without any special effort. If the movement of the element is difficult - it is a sign of excessive tension.

At strong tension the cutting element of the chainsaw tire begins to heat up and grind down, the engine load increases, and it wears out quickly. Switch on unit with loose chain It is forbidden, as it can be clamped and cut off when sawing, which is dangerous for the user of the machine. The chain can fly off the tire and injure the limbs, while it often damages itself and damages the tire. Also, work with a weakened chain element leads to one-sided tire wear, after which the device stops making even cuts, and the saw leads away.

Major Chainsaw Chain Problems

Chainsaw users are often faced with the problem of tensioning the saw chain. It either spontaneously weakens, or stretches and flies. As a rule, these troubles are caused by unit breakdowns. Therefore, before proceeding with the procedure of stretching chain links,check for and eliminate possible causes that could lead to an adjustment disorder.

Reasons that chainsaw chain stretched, there may be heavy loads or insufficient lubrication to the tire. Because of this, the saw overheats, the metal expands, the dimensions of the saw element increase, and it flies off the tire. Oil intake can be broken if the pump breaks, channels are blocked, the oil hose is broken.

If you changed the chain on a chainsaw to a new one, then be prepared for the fact that during the period of running it will stretch a little. It is only necessary to check the tension in time so that the element does not fall off the tire.

A chain made of poor quality steel is also subject to rapid stretching.

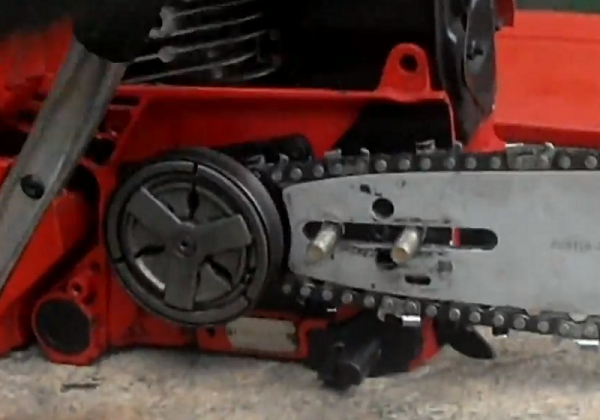

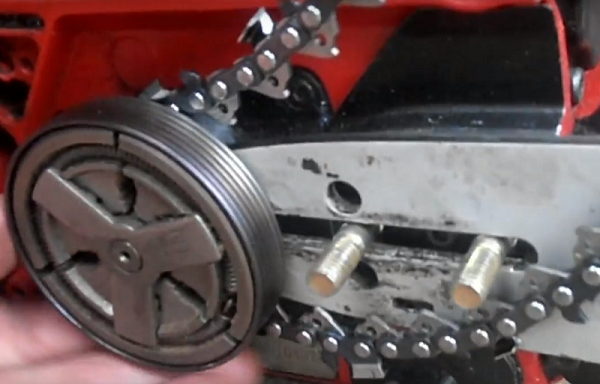

When the driven or driving sprocket is worn, the coupling efficiency with chain links decreases, resulting in saw unit flies off. In this case, you have to unscrew the drive chain and change the sprocket. Also, the saw blade of the unit can fly due to its stretching or deformation of the tire.

If on your chainsaw the chain weakens, then a malfunctioning tension mechanism may cause this malfunction.

Tension algorithm

Before tightening the chain on the chainsaw, you must shut down the engine of the unit, or disconnect it from the network if it is an electric saw. Do not adjust or replace the saw element if it is in a heated condition. If this is done, the metal after cooling will compress and the tension will be too high, which can lead to increased engine load and tire deformation.

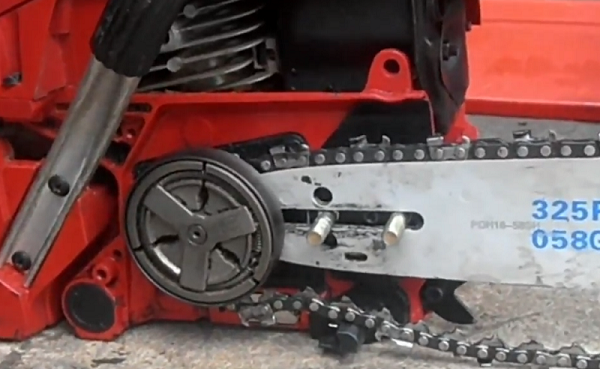

Chain tensioner is located on the right side of the unit, under the cover, in the place where the brake with clutch is installed, and the tire mounting. On the Husqwarna, Stihl, Poulan and Partner chainsaws, the external tensioner looks like an ordinary bolt.

So, to make the adjustment of the chain element of the apparatus, you must perform the following steps.

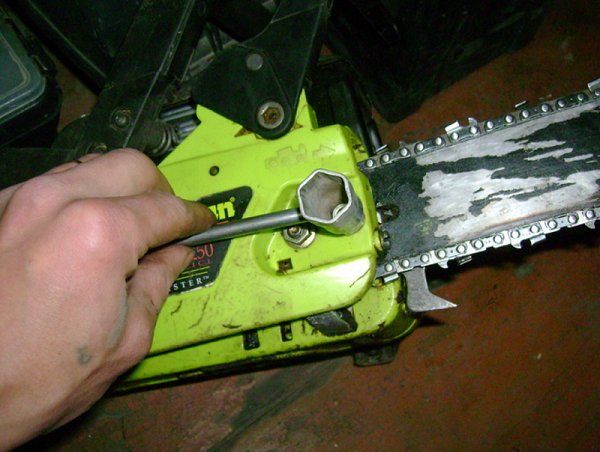

- Slightly loosen the nuts on the right cover so that the tire does not skew.

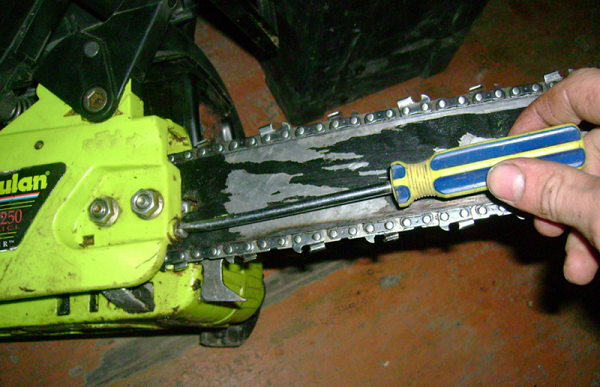

- After inserting the screwdriver into the tensioner adjustment bolt, start turning it to the right (clockwise). From these actions, the tire will start moving, and the chain tension will occur. If you rotate the bolt to the left (counterclockwise), the chain links will relax.

- Next, you should tighten the chain to the state so that it does not sag and dangle.

- Check the degree of tension of the element: grasp the cutting link approximately in the center of the tire and pull it down with a slight effort. The chain should be tensioned, have elasticity, and the shank of the cutting link should fit into the tire groove about 1/3 of its height.

Makita electric saw the tension adjuster is designed in such a way that it can be turned without using any tool. Rotating it clockwise, you will tighten the chain, if you rotate the regulator in the opposite direction, the tension of the chain element will weaken.

Replacing the saw element chainsaw

If replacement of the chain on the chainsaw is required, then follow these steps.

- Remove the cover covering the sprocket. For this, it is often necessary to unscrew the fastening nuts.

- After unscrewing the fasteners, remove the cover covering the coupling with an asterisk.

- Holding the tire with your hand, move it towards the sprocket to loosen the chain.

- Remove the chain element from the drive sprocket.

- Now you need to install the chain on the chainsaw. Take a new sawing element and first put it on the drive sprocket.

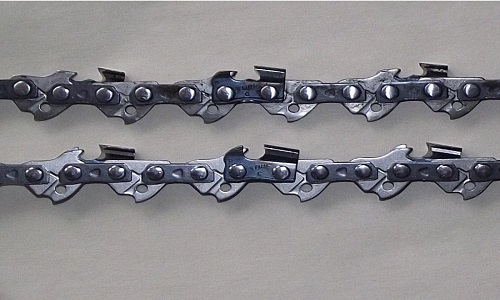

- Then you need to put the chain on the tire, putting the element in its groove around the perimeter.It is important that the links are properly dressed on the driven sprocket located on the top of the tire. When installing, pay attention to cutting link direction. They should be directed in the opposite direction from the unit, on the top of the tire.

- Feed the tire in the opposite direction to the engine to tighten the chain slightly.

- After laying the saw element, before putting the cover back in place, it is necessary to combine the screw, through which the tension is adjusted, with the regulator located behind the tire. Only after that you can put on the cover and slightly tighten the nuts. Next, insert a screwdriver into the adjusting screw and apply the final tension. How to make the correct stretch of the chain, it was described above.

- Raise the tire slightly and tighten the nuts, thus securing it. It is important not to overdo it and not to break the thread.

Is it possible to shorten the chain yourself

In the case when the chain of chainsaws stretched so much that it no longer stretches, it becomes necessary to reduce its length.

Also, this has to be done if the existing tire is shorter than the chain, and there is no possibility to choose a suitable sawing element.

Can and build up the saw elementby adding new links that can be purchased separately or removed from the same. In the shops you can see the chain for chainsaw, wound on the bay, which is sold on the meter. In general, repair chains for chainsaws can be made at home, because to find all the components for it is easy.

How to remove the rivet

To change the elements of the chain or shorten it, you will need to disconnect the links as follows. Lock the chain in a vise and shake off the rivets, namely, their protruding parts. For this you can use a file or files. Ensure that the side sections of the link are not ground.

The use of the grinder is not recommended because there is a risk of overheating of the links, which will lead to a change in the physical properties of the metal.

Using the beard (as it looks, shown in the photo below), knock out the rivet.

There is another option for the separation of links. You do not need to grind off the caps of the rivets. Place the link, namely its rivet, over any hole in the metal or over a slightly diluted vise jaws.Next, you should put the fitter on the head of the rivet and hit it several times with a hammer.

Continue to knock out both rivets alternately, as they are rigidly fixed to the opposite part of the link. Gradually, the rivets will begin to exit the top of the link, and it will disconnect.

The advantage of this method is that the rivets can be reused because they do not grind.

How to connect links

For starters, you need to purchase links in the specialized shop that match the type of chain you have. This will have to do if you grind rivets when disassembling the chain element. Then take proper link assembly taking into account the arrows indicated on it. Put the assembled element on the anvil and rivet the rivets with light hammer blows.

Do not be afraid to rivet, since the rivet has a thickening in the central part, which serves as a stopper.

Some craftsmen advise linking by welding. This method is suitable if the rivets were cut with a file. But first you need to experiment on any piece of hardware to select the appropriate welding mode.

Welding must be carried out with a shortened and thin electrode.The rivet is welded to the side of the link, and the excess metal is removed with a needle file. The only drawback of this method is overheating of the metal from which the chain elements are made. As mentioned above, due to overheating, the wear resistance of the links may decrease.

/rating_on.png)