Which chain is better to put on a chainsaw

Chain is a key element of any chainsaw. The quality and speed of work when sawing wood depends on the type of cutting tool installed on the unit. For novice users of chainsaws, choosing a saw chain seems to be a difficult process, since you need to know what types of a given part there are, its characteristics, etc. The article will discuss the main factors that should be considered to choose a good chain for chainsaws.

Content

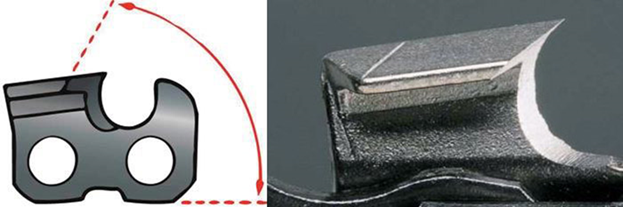

Types of chains for chainsaws

Those who are faced with sawing wood, know that you can cut it, either along the fibers, or - across.On the basis of this, different types of chains for chainsaws are produced: for transverse or longitudinal cutting wood In both cases, the difference in resistance of the material will differ significantly. For longitudinal sawing, the teeth are sharpened at an angle of 5 to 15 °. Cross cutting requires sharpening the tool at an angle of 25-35 °. The figure below shows how the sharpening angle of the teeth is determined.

What type the saw element belongs to can be learned from marking on it, moreover, the angle of sharpening is determined visually.

Chains for longitudinal sawing are rarely used, because it is much easier to disband the workpiece on a circular. Due to the low demand, manufacturers of this tool are not particularly engaged in its improvement, and it is rather difficult to find a chain for longitudinal sawing for sale. Most buyers of chainsaws choose a tool with a transverse type of cut, and it is the most popular among both professionals and home craftsmen. But, before you choose a chain for a chainsaw, you should study the main parameters that affect the performance and quality of the tool.

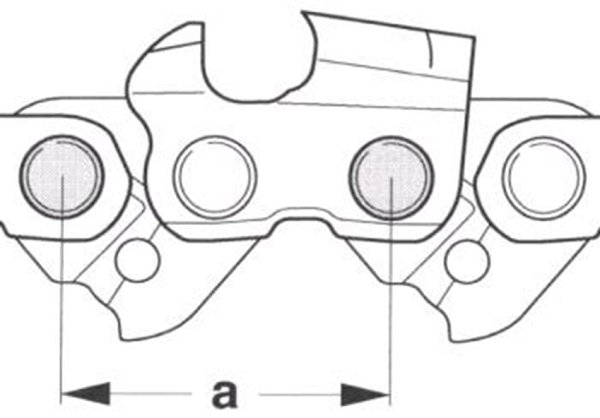

Existing step sizes

Chain pitch is a key parameter that requires special attention when choosing a cutting element for a chainsaw. It is measured in inches and is defined as the gap between the cutting links or the gap between the three rivets of the saw element. The following image illustrates how chain pitch is determined.

Each saw has an individual chain pitch.

It is worth noting that the pro class tool works with any kind of chains.

Chains with a certain pitch are always intended for units of a certain power, taking into account the torque. Reducing the step not only reduces the performance of the device, but reduces the load on the engine. Conversely, with a large stride increases the productivity of the device, but more power is required.

In addition, there is such a thing as “Aggressiveness” of the unit. In this case, refers to the ease of management. The larger the step, the more forcefully the teeth “tear” the wood. In addition, due to the large size of the cutting links, the width of the cut increases and, therefore, the operator will need to exert more effort to hold the device in his hands. Based on the foregoing, you should not use a chain with a large pitch on a low-power unit, because this way the device can be rendered unusable.

0.325 inch pitch

This is the minimum step value, but, nevertheless, the most common. The saw elements having this step are usually installed on amateur and semi-professional units having a small power - in the range of 3-3.5 hp. This is enough to easily cut the branches, cut down thin trees, carry out minor construction work. The 0.325-inch chain runs smoothly, without vibration, does not “tear” wood, does not overload the engine, and does not tire the operator.

Step 0.375 or 3/8

Marking may look like decimal or ordinary. There is no difference between these designations: three divided by eight will result in 0.375. Ordinary fraction in the marking is designed to eliminate confusion between the numbers 0.375 and 0.325.

For this reason, there are cases that it is difficult to find an element in 0.375-inch increments on sale. If so, try searching for the same part labeled 3/8.

These chains are installed on more powerful units - having 4 hp.Such saw elements can cut down trees of average diameter. Chains with a pitch of 3/8 inches are installed on semi-professional chainsaws and units of the pro class.

Step 0.404

Saws with such a step set only on professional units with a power of at least 5.5 hp Sawing with a step of 0.404 inches can cut down trees of any thickness, and the units for this cutting element have a large torque, which greatly facilitates the work of a person.

It is important to know that the chain pitch always corresponds to step stars, as a slave, and leading. From this it follows that if the documentation for the device states that it works with a chain that has a pitch of 0.404, then you should not put the chain on a chainsaw with a pitch with a 3/8 pitch. Before installing the circuit with a different pitch, you need to purchase a complete set, including both a tire and both sprockets: driving and driven.

In addition to the above step values, there are two more: it is 1⁄4 (0.25) inches and 3⁄4 (0.75) inches. Saws with such a pitch are not very popular, both among professionals and home craftsmen.

The thickness of the leading link (tail)

This parameter is the second most important when choosing a saw element.You should know that on different brands of chainsaws the tire will differ in width. Leading units are also intended only for a specific type of tire.

Leading links are of the following sizes.

- 0.043 "or 1.1 mm. This is the smallest lead link. It is usually installed in miniature circuits, which are designed for “weak” household units, not intended for heavy loads.

- 0.05 "or 1.3 mm. Although the difference with the previous example is not significant, the cutting element is designed for more tangible loads. Chains with a link of 1.3 mm are most common among owners of household and semi-professional chainsaws, they are lightweight and fairly reliable.

- 0.058 ”or 1.5 mm. This type of saws is not less popular than the previous one, but it is used not only in a semi-professional tool, but also in pro devices.

- 0.063 "or 1.6 mm. Chains with such a ponytail thickness are more durable and are put only on the tool for professionals.

- 0.08 ”or 2 mm. This size is the final among the types of leading links. The chain is designed for continuous operation and serious load. It is not difficult to guess that the element is used only on highly professional chainsaws with high power.

As a result, the greater the thickness of the leading link, the stronger and more qualitative the chain, and the greater the load it can withstand. But, choosing a cutting element, it is necessary to consult the instructions to the device, which indicates what size the tire is allowed to install on it.

Cutting depth and profile height

The depth of the cut depends on how high the profile of the chain is. The higher the profile, the stronger the chain “bites” into the material, and as a result, the tool productivity increases. With a low profile, thinner chips are removed, and the chain is not so deeply immersed in the material. Typically, the depth is controlled by grinding down the stops that are located on each tool.

There are the following profile sizes:

- high profile - 0.03 ”(0.762 mm);

- low profile - 0.025 ”(0.635 mm).

This information can be found in the documentation for the chainsaw. These types of profiles are installed on amateur and professional units. But you should know that the tool of the class of the pros can not always be equipped with high-profile chains, and the household tool is always equipped with low-profile cutting elements.

High profile chains - these are the most productive elements, which means they have increased “aggressiveness” and, in addition, a perceptible vibration. The latter significantly reduces labor productivity, as it does not allow working with the unit for a long time. Therefore, manufacturers have found a middle ground: with a large stride, a chain with a low profile is made, and vice versa, if the step is smaller, then the profile is made high. These changes remove all side effects as much as possible, the unit begins to work with less “aggressiveness” and normal performance.

Which profiles are better is hard to say. When choosing, you should always focus on the intended working conditions, hardness or viscosity of wood, etc.

Tooth geometry

Cutting links have 2 types of profile.

- Chipper, which is popularly called “sickle”. Such a name it has because of its crescent shape. Thanks to the chipper tooth geometry, the saw provides high performance, easy to sharpen, which does not require perfect angles. The disadvantages of such a geometry of teeth include the possibility of increasing the load on the unit and reducing the cutting qualities of the saw.

- Chisel, popularly called the “seven” because of the similarity with the same number. "Seven" is mainly used on the instrument class pro, on chains with a step of 3/8 or 0.404 inches. The main disadvantages of this tooth geometry are difficulty in grinding and quick wear if dirt comes in.

Tire size

In addition to the thickness of the tire, which was mentioned above, when choosing a chainsaw, one more parameter should be considered - the length of the tire. It is measured in millimeters or inches. Tires of the following sizes are often used: 11 ″, 12 ″, 13 ″, 14 ″, 15 ″, 16 ″, 18 ″, 20 ″, 21 ″, 22 ″.

For simple work, such as cutting branches, cutting thin boards, you can use small tires - 11 or 13 inches. The chain on such tires accelerates to high speeds, which has a good effect on performance. Considered the most versatile tire sizes in the range of 14-16 inches. In addition to the use of the unit as a delimber, a chainsaw can be used when harvesting firewood (sawing thin logs). To cut a thick log, install tires 18-22 inches. Usually they are used on semi-professional and more powerful, professional chainsaws.

You should not install a larger tire,what is indicated in the passport to the unit, since this will inevitably lead to an increase in the load on the engine and, as a result, to its rapid wear.

Chain size

This parameter always depends on tire sizeinstalled on the unit. If you accidentally purchased a smaller chain than your tire, you won't be able to wear it. If this element has a size larger than the size of the tire, you can not pull it. Both options do not allow the use of unsuitable size chains. They are usually specified in inches and have the following values: 10 ″, 12 ″, 13 ″, 14 ″, 15 ″, 16 ″, 18 ″ and above.

The chain length is determined by number of links. Under the links refers to the connecting links that go into the groove of the tire, and not cutting teeth. When buying, you can specify the seller or the length of the part in inches, or the number of links in its composition. Some manufacturers instead of the length indicate the number of links in the saw element. As a rule, this number does not depend on the thickness of the tail, the step and the height of the profile. For example, a low-profile chain, having a leading link of 1.3 mm, may consist of either 72 links or 56 links or another number of them.

The order of the cutting links

In most cases, the order of placement of the cutting elements can be of three types.

- With pass. A connecting link is inserted after each cutting tooth.

- With half pass. A connecting link is installed between each pair of cutting links.

- Standard. Each cutting tooth is fixed by two connecting links.

Cutting links are the main elements of the saw chain and are expensive due to the complex manufacturing process. Manufacturers, changing the order of the cutting teeth, reduce their number and thereby reduce the cost of the finished product. But at the same time, due to missing links, the efficiency of the tool operation is noticeably reduced, and the chain wears out faster.

Carbide chains

Win - it is a very hard alloy, superior glass to strength. Therefore, household glass cutters, various cutting and lathe tools and turning tools are made from it, as well as it is applied to the saw chains of chainsaws. Wins soldered to the cutting links, where it plays the role of durable cutting edge. But despite its hardness, this alloy is brittle.

The service life of chains with taps from victor considerably exceeds the life of standard cutting elements. Carbide chains are used for sawing frozen and hard wood, as well as emergency response measures, if you need to quickly cut reinforced or plain concrete.

The disadvantages of carbide chains can be attributed to their high cost, exceeding the price of conventional cutting elements several times.

Chains for chainsaws with pobeditovy napayka in amateur practice are used very rarely, because they are intended for semi-professional and professional tools that have good power and high torque.

Top brand chains for chainsaws

According to the reviews of the owners of these units, a rating of chains for chainsaws was made. Below are manufacturers that produce the best chains for chainsaws.

- Stihl is a very famous Swiss brand, which produces saw chains from high strength chromium-nickel steel. They do not stretch when heated, as usual. This is achieved through the use in the manufacture of a special method of hot riveting.Above all, this manufacturer has patented the lubrication method - the “grooves” with which all the driving units are supplied.

- The company does not design circuits, but produces them using the best patented technology. Thanks to this, high product quality is achieved. The company also provides a large range of services to customers, providing warranty service for their products. In addition, customers of the company have the opportunity to purchase original spare parts for mechanisms.

- Oregon is a division of Blount Inc. The company is considered one of the best among the companies producing sawing elements for chainsaws. Oregon also produces various accessories and spare parts for tools of other famous brands. The saw elements of chainsaws are made of a special patented alloy, and chrome alloy is applied to the teeth. To facilitate the sharpening process, markings are made on the teeth, indicating the angle at which the operation should be performed. In addition, the chains have a system that allows to reduce the vibration and the original design, thanks to which the lubricant is distributed evenly.

- Carlton is a company from America.All elements of the chain of this manufacturer have increased hardness, since they are shot blasting at the manufacturing stage. Cutting units have a long edge, making it possible to produce a large number of sharpening.

- Windsor. The company has patented a heavy-duty alloy, which is characterized by high heat resistance and is not subject to stretching. Windsor sawing elements are stamped and riveted to ensure high reliability.

- The chain is made of alloy steel with chrome teeth. The latter are sharpened in a special way, and a hypoid lubricant is applied to the chain, facilitating the cutting process. The company also applies the method of shot peening in the manufacture of chains, which increases the strength of the links.

/rating_on.png)

/rating_off.png)