Is it possible to repair the induction cooker with your own hands

Besides all the obvious benefits, induction cookers they have one feature that is directly related to the mechanism of operation of the equipment - this is the difficulty of self-diagnosis and the repair process in case of a malfunction. However, having some initial skills and information from this article, you will be able to repair the induction cooker with some simple breaks with your own hands.

Content

Basic faults induction plates

Induction plate breakage can be classified into the following types:

- insufficient power;

- one or more burners broke;

- stove completely out of order;

- the hob does not turn on.

Before you start repairing your hob, make sure that it is disconnected from the power supply.

Insufficient power

The most common cause of such a malfunction is power cable damage. Unplug it from the outlet and check for defects. If found, replace the cable.

If the diameter of the bottom of the dish does not match the diameter of the burner, there may well be problems with the heating rate. It should be remembered: induction cooker is very demanding the choice of dishes. Check that your pan or pan fits tightly against the surface of the stove. When loosening pressure springs it is possible to repair the induction cooker - you just need to tighten them to the level specified in the instructions.

Matching the size of dishes with a hob

One or more burners broke

The likely cause of such a breakdown is wire breakageproviding coil connection to the mains. If you have the skills of soldering, then you can do the repair yourself, if not - entrust the matter to a professional workshop worker. Otherwise, you can only exacerbate the breakdown by adding a pair of zeros to the cost of the repair.

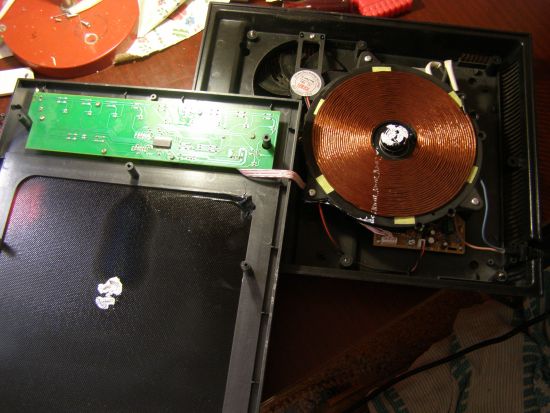

Induction coil burnout - a rare case arising from the operation of induction cookers. Repair in this case will consist in simple replacement of the blown coil with a new spare part. Replacement is a complex process that is recommended to entrust to specialists.

The stove is completely out of order.

The most common problem leading to the complete inability of the hob to perform its functions is thermal breakage failure or transformer. In order to make a diagnosis, you must perform the following steps.

- Check the power source for the presence of the required voltage.

- Ensure that the power cable and plug are in working condition.

- Carry out the process of dismantling the induction cooker. To do this, disconnect the electrical wires and unscrew the panel from all fasteners.

- A special device is used to test the transformer and fuse. — a multimeter that measures the specific resistance of certain sections of the circuit.

- If resistance is found on that part of the circuit where it should not be, replace the corresponding element.

Multimeter to check voltage

Before as install induction cooker to the original place, make sure there are no damage to the connections. Problem areas that need special attention are the control unit, thermostat and power switches.

The hob does not turn on

To repair the induction hobs with their own hands in this case, first of all, you need check fuse. In case of breakage, it is necessary to replace it with a new one. There may be several reasons why a fuse could fail:

- the fuse did not cope with the load;

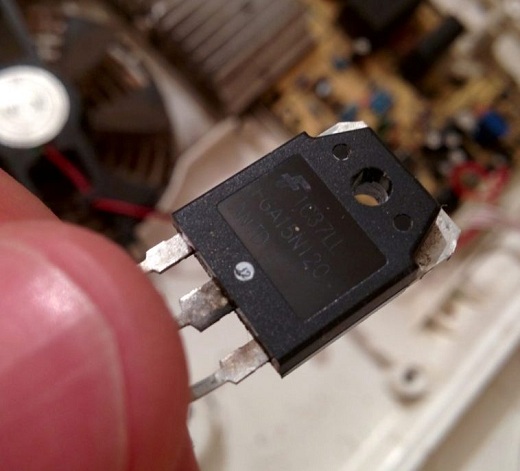

- short circuit transistors.

Induction Plate Transistor

To test the transistors for a circuit, follow these steps:

- disassemble the induction cooker and disconnect the board;

- carry out the "ringing" of transistors and a diode bridge using a special device multimeter;

- in case of detection of resistance on the sections of the chain, replace the broken elements;

- assemble the system and carry out the repeated “ringing” of the chain.

Important: if you do not have at least basic skills in the field of electronics, contact a specialized workshop in which you will be provided with professional assistance.

To avoid problems with induction panels, observe rules of their operation.

/rating_on.png)

/rating_off.png)