Frequent breakdowns of induction plates

The most progressive development in the field of cookers can be considered as an aggregate with induction hob. This technology attracts buyers because it does not need to use gas, as well as its novelty. But, despite the high technology, faults in induction cookers occur no less than other household appliances.

Content

- 1 Insufficient heating power

- 2 One of the burners does not work

- 3 Left pair of burners does not work

- 4 The right pair of burners does not work

- 5 The plate does not turn on and there is no indication

- 6 Residual heat indicator not working

- 7 Cooling Fan Malfunctions

- 8 High-power burner does not turn on

- 9 The plate is automatically shut off

- 10 The hob is buzzing at work

Insufficient heating power

This plate malfunction may cause wrong arrangement of the pan on the stove: not in the center of the burner, but at the side, or that the dish itself is of a smaller diameter than the hob itself. If everything is in order with the diameter of the cookware, then the fit of the induction hob to the glass-ceramic panel should be checked. In case of not tight contact with the panel, achieve a good fit with the help of special pressure springs.

When the indicator flashes between the set power indicator and the low value, it can be said that the control unit automatically reduced the capacity of the cooking place due to overheating of the induction coil. In such situation The state of the coil is checked.

One of the burners does not work

At the very beginning, including the panel, the required hot plate is selected using sensors. Only after selecting it, you can set the power level. If the correct sequence has been observed, but the inclusion does not occur, check what the dishes are made of. It must be either metal or cast iron, that is, have magnetized property. Ware from aluminum and copper for induction plates is not suitable. Also, it will not be possible to cook on such a cooking surface in glassware.

In the case where the dishes match required standards, but the problem remains, it is necessary to start execution test programsto check the burner temperature sensor. If it fails, it must be replaced. With a good sensor, the tightness of the induction module against the glass-ceramic panel is checked. If necessary, the fit is regulated by pressure springs.

Left pair of burners does not work

In order to find the reason why the unit of hobs on the left is not turned on, it is necessary to check all the connections from the coils to the control unit and to the power board. If you find that there are no connection problems, you need to replace the control unit. In the absence of positive results, the burner block should be replaced.

Signal about bad contacts in the wiring between the modules of the unit can error codes on the display. In this case, the code “E8” appears.

The right pair of burners does not work

In the search for a fault in the Bosch induction hob or the same cooker from another company, you should check the contacts in the terminal box, as well as the fuse status of the coil unit. At blown fuse, it needs to be replaced, with a new one, with the same marking. If there are no changes to the positive side, conduct the test, as described above, for the left pair of cooking places.

Also on the LCD display may appear error code “E6”. This error means that the induction hob is out of order. It is recommended to unplug the unit for 30 seconds and then turn it back on. If the error codes reappear, the control panel will need to be replaced.

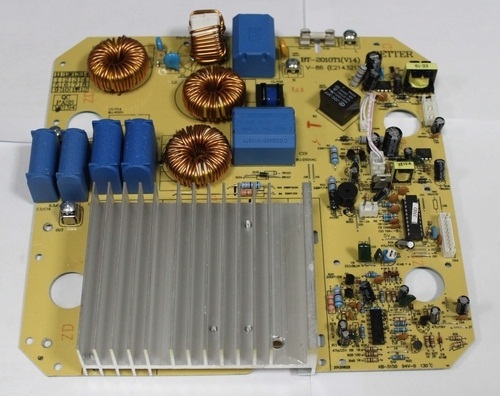

The plate does not turn on and there is no indication

First of all, you need to check the fuse, and then - the network switch. The next step is to check the connection between the control unit and the power board. Then between the control unit and the touch panel. If a failed module is detected, it must be replaced. If replacing the module did not help, the entire coil unit changes.

Confirmation of problems in the touch panel can serve error code “Е9”which appears on the LCD of the device. Based on the list of error codes, it means that the touch control panel is faulty. It is recommended to disconnect the device from the network for 30 seconds. When the error reappears, the control panel changes.

Residual heat indicator not working

Need to run software test to test the temperature sensor. If it is healthy, the control unit changes. There are cases when the elements of the LCD display are lit constantly or not all work. With such a fault, the quality of the connections between the control unit and the touch panel is checked. You can try to replace the cable connecting modules. If this does not work, the control unit must be replaced.

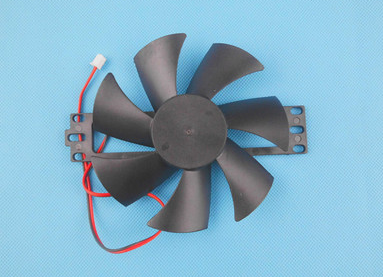

Cooling Fan Malfunctions

The cooling fan can work without stopping if you set maximum heating power for burners. Also, it may not turn off if the air temperature around it is more than 50 ° C. Otherwise, the malfunction may be caused by a faulty control unit to be replaced.

In this case, the aggregate may also display error codes on the display. For a faulty fan, this will be the error code “E7”.

There is also a reverse situation - the fan does not turn on. This behavior can be considered normal when the power level of the hob is minimal.It should turn on when the temperature of the air around it rises. above 50WITH. To test the fan, a test program is started. If it shows that the mechanism has failed, then it needs to be changed.

High-power burner does not turn on

There are situations when you want to turn on the most powerful burner, with a maximum power of 3 kW, but nothing happens. This is considered normal if other hotspots work, and the temperature around the induction coil unit exceeds 780 degrees. When you turn on the most powerful burner to exclude unit overheatingit is locked. When the hobs are cool, the lock will be released and the coil will turn on. But, if the burner does not turn on, you will have to change the control unit.

The plate is automatically shut off

The induction cooker can switch off automatically in the following cases:

- if you turned on the unit, and for 10 seconds you didn’t perform any actions on the touch panel, for example, you didn’t select the cooking place, didn’t set the power, and so on;

- the work of the burners lasts more than 2 hours;

- if the electronic timer has been triggered, on which the stopping time was set.

In other cases, when the stove can spontaneously shut off, one cannot do without the help of a qualified specialist, as it will take replacement of the control unit or the entire induction coil unit.

The hob is buzzing at work

An induction cooker may emit various noises during operation, and they may occur for the following reasons:

- the machine can buzz if they put it in the hob pot with a thin bottomor excessive power is set;

- the stove often buzzes or whistles when mounted on a large hob of a small saucepan;

- vibrations can occur at the junction of various materials, when the bottom of the pan consists of several layers;

- The intensity of the noise depends on the amount of cooking utensils on the hob.

With a constantly sounding sound signal, it can be assumed that the reason that it does not turn off is in the control unit, which is repaired only by replacing it with a new one.

If the cause of the breakdown has not been established by you, or you have difficulties with how to purchase and install the failed modules, then it is better for induction cooker repair turn to professionals. You should also remember about the warranty service, the right to which you can lose when self-opening the unit. Induction hob is a “smart” technique and requires careful adherence. operating rules.

/rating_on.png)

/rating_off.png)