Checking the temperature sensor in the washing machine

Thermal sensor - a special device that controls the heating of water in the drum. It monitors the desired temperature and turns off the heater in time to save energy. If suddenly your device stopped heating water or spends on it too much time, perhaps it is in this sensor. We learn how to test the temperature sensor in the washing machine.

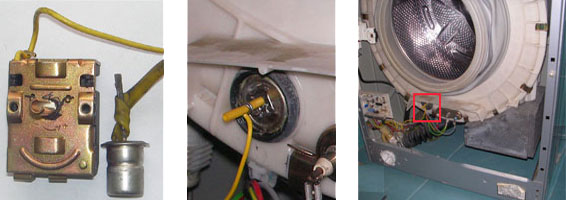

Sensor location in the washing machine

Content

Functionality check

To check the temperature sensor it is necessary to provide access to it. To do this, de-energize the washer and shut off the water supply. Then you have to dismantle the outer panel and some internal parts. The easiest way to remove a thermistor from the system is because it is located directly in the TENe. In popular models, such as Indesit and Samsung, a thermal sensor is installed at the bottom of the system.

To dismantle the thermistor will require:

- remove the back of the machine;

- disconnect the thermal sensor from the wires;

- loosen the mounting of the heater;

- remove thermistor from system.

After dismantling the sensor, you will need multimeterto measure resistance. This is done in this way:

- Set up the multimeter and get ready to test the resistance.

- Connect the gauges of the device to the contacts of the thermal sensor. Remember that when the temperature reaches twenty degrees, the resistance should be no higher than 6000 Ohms.

- Lower the temperature sensor into the water and carefully monitor the multimeter. In the case of proper operation of the sensor, its resistance will begin to decrease. In the water temperature of thirty-five degrees, it will reach the mark of 1350 Ohms.

Important! If you find a broken sensor, immediately replace it with a new one. This part is not subject to repair, and in a faulty condition may lead to breakdowns.

Common Damage

Most often in these sensors the copper tube which acts as the conductor of freon fails. As a result, the sensor functionality is violated, and you have to replace the part with a new one.Having got a new spare part, install it in the place of a failed one.

External signs of problems in the sensor can take the following forms:

- wash with any mode and arbitrarily chosen temperature is still carried out in boiled water;

- The outer panels of the washing machine get very hot during operation, it can swirl steam.

The presence of these signs indicates an urgent need to replace the heating control device. Further operation of the machine with an inoperative sensor can lead to serious damage to the entire system or burnout of the heater. Replace failed TEN will be quite troublesome and expensive.

Different types of thermal sensors

In modern models most often one of three types of sensors is installed:

- gas filled;

- bimetallic;

- thermistor

They differ primarily in the device and features when replacing.

Gas filled

This type of sensor is constructed from two parts. One of them is made in the form of a metal round bar with a size of 20 -30 millimeters. This part is located in the inner part of the tank and measures the temperature of the water when it comes into contact with it. The second part of the gas-filled sensor is made in the form of a hollow copper tube.It is connected to an external temperature controller, which is built into the program control panel.

Sensor inside filled freon. When exposed to high temperatures, it expands, causing the closure of contacts connected to the heater.

Gas filled thermal sensor

Bimetallic

This device is made in the form of the same tablet as the first one. Inside this detail is located bimetallic platecurving when exposed to temperature. This causes contact closure and termination of water heating.

Bimetallic thermal sensor

Thermistor

Now the third type of thermal sensors is gaining popularity, namely a thermistor. Made in the form of a cylinder with a diameter of 10 millimeters, it is installed directly on the heater. He works on principles resistance changes, and its main advantage is considered a simple replacement.

Remember that the temperature sensor is an important part of the washing machine. Timely replacement of worn parts and compliance preventive measures can save you from costly repairs and extend the life of your vending machine.

/rating_off.png)