Features self-assembly induction water heater

Today, when organizing water heating, an induction water heater has become very common. This demand is ensured by the fact that the device is completely environmentally friendly, does not dry and does not burn through the air. The use of such a device can be implemented for flow-through heating of water or as a heating boiler. You can buy an induction water heater in the store or do it yourself. It is worth noting that, in terms of technical characteristics, it will not yield to the purchased model, although it will not look so attractive, but it costs much less.

Content

Instrument Features

The use of such a device in the home allows for maximum performance and reliability in operation.At the same time, the unit does not need to be accompanied by special documentation and permission for installation, for example, as a gas boiler. Using an induction heater as a traditional heating boiler, in some cases it will not be necessary to use a pump. The movement of the coolant is achieved by convection processes: water with a large heat turns into steam.

It should be noted that the induction water heater has many advantages that distinguish it from competitors.

- The cost of such a device is negligible.

- It is possible to assemble the heater yourself.

- Does not make extraneous noise. The coil in the process of work vibrates quite strongly, but it is almost not noticeable.

- Due to the constant vibration, dirt and scale does not have time to attach to functional elements, therefore the device does not need regular cleaning.

- In its composition has a heat generator, which is very easily made hermetic. The water serving as a coolant is placed in the heating element, thanks to which energy is transmitted through a magnetic field. It does not require the use of contacts, and, accordingly, glands and various sealing gum, which have the feature to quickly fail.

- It rarely breaks, as a simple tube is responsible for heating the water, in which there is simply nothing to break or burn out.

Choosing an induction water heater, the owner receives the device with minimal maintenance, as it consists of a small number of components. And they, in turn, very rarely fail.

The principle of operation of the induction boiler

But without the drawbacks can not do. As with any kind of technology, they are.

- High power consumptionwhich will result in large bills for the light;

- The device is very hot, and everything around becomes hot, so you should not touch the device during its operation.

- Induction water heater has a strong heat transfer, therefore installation is necessary temperature sensorto prevent overheating of the device, and, accordingly, an explosion.

Types of induction water heaters

All devices of this type, which can be made by hand, can be divided into two groups:

- Vortex heaters inductor typewhich are most often used in homes to perform heating functions. It is their manufacturing process that will be discussed below.

- Heaters, the design of which involves the use of different types of electronic components and parts.

While creating induction vortex heater (or abbreviated VIN) with your own hands, you should provide the following structural units:

- the element responsible for the conversion of electricity into a high-frequency current;

- inductor (most often performed in the form of a cylindrical element of copper wire), which, when used, performs the function of a transformer responsible for the formation of a magnetic field;

- the element that will play the role of a heating element is located inside the inductor itself.

Work VIN as follows.

- High-frequency current from the converter is transmitted to the inductor.

- In the inductor is formed a magnetic field, which in turn creates flows of a vortex character.

- Heat exchanger under the action vortex flows rather quickly reaches a high temperature and, accordingly, heats up the coolant, which distributes heat further.

Scheme of a modern water heater

One of the most important components is the induction coil, the manufacture of which should be taken with special care.Copper wire is very carefully wound on a pipe made of plastic, and the number of coils should not be less than 100.

From the description provided, it can be concluded that it is not difficult to make an induction water heater on your own.

Manufacturing features

Induction heater with your own hands can be made in two ways. Briefly worth considering each of them.

Option 1

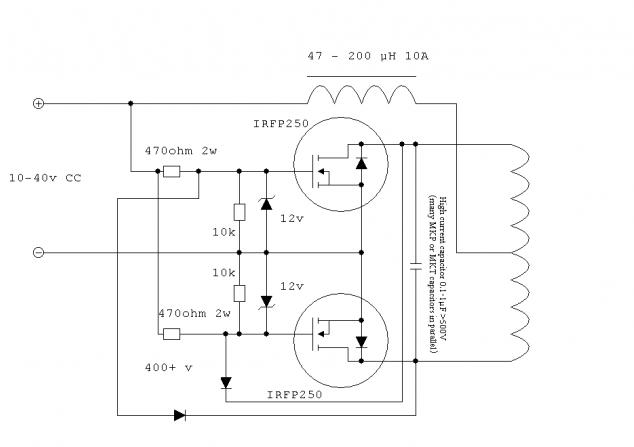

The simplest device (at the same time it will have high power) can be made on the basis of printed circuit. Among the features of the circuit to be used in the device, the following points should be highlighted:

- the whole structure, in fact, is represented by a multivibrator with high power organization;

- Particular attention should be paid to the resistance, since it will prevent the transistors from overheating;

- the inductor in this device should be made in the form of a spiral of 6-8 turns of copper wire;

- As a regulator, you can use the corresponding element from the computer's power supply and not worry about its contraction.

Experts recommend: to avoid damage due to the release of strong energy, transistors are best installed on radiators of a special design.

Induction vortex heater

Option 2

The basis for the manufacture of such a device with their own hands is the use electronic transformer.

The essence of this method of manufacturing an induction water heater is as follows.

- Two pipes with the use of welding should be connected so that visually they resemble a donut. This element will subsequently play the role of both the element for heating and the conductor.

- Copper wires will need to be wound on the case.

- To ensure high-quality and rapid movement of water, 2 pipes are welded to the main body. Water will flow into one of them, and from the second it will go out into the system itself.

That's all the tips on how to assemble such a heating device with your own hands and provide high-quality heating in the house and the constant presence of hot water.

/rating_off.png)