Cleaning the gas column with their own hands

In regions with natural gas, it is most advantageous to install a water heater that works on this particular fuel. Convenient and economical, it will last a long time, especially if you pay due attention to the care of the device. Cleaning the gas exchanger must be carried out at least once a year. Some work in this event can be done on its own, but for this you need to know how to properly and accurately clean the gas column.

Content

The nature of pollution of gas columns

This technique is a simultaneous representative of two types of household appliances (water and gas). Consequently, problems can arise in two directions at once.

- Because of the hard water, the salts in it can settle on the walls of the pipes leading to the column. in the form of scum. Clogged "contributes" to the uneven distribution of water, until the complete cessation of its receipt.

- The gas part of the unit accumulates in itself the final product - soot. Also carbon deposits are formed here. Soot will reduce normal thrust. The problem can be called started when soot flakes start falling out from under the steel frame of the device.

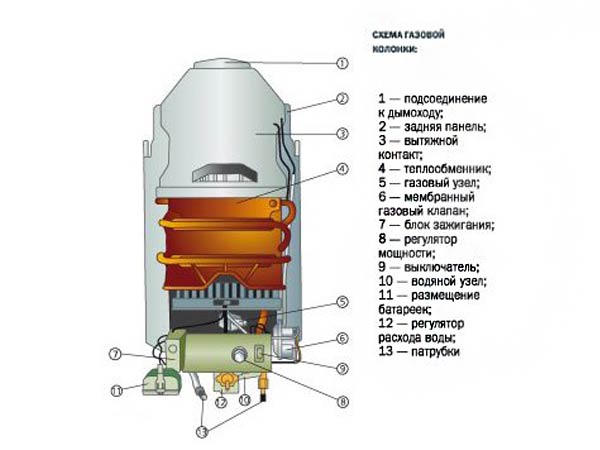

How does such a unit

A brief overview of the "entrails" of the device will help in the future to understand how to clean the gas column. Externally, the unit usually resembles a metal box - a pair of pipes (with gas and cold water) is supplied to it. Inside are located:

- heat exchanger;

- igniter;

- main burner.

The principle of operation of the unit is as follows: the user opens the tap from hot water, at this time the ignition will automatically operate in the gas column (in modern technology, electrical or piezo ignition is programmed). This activates the igniter: the process ignites the main burner, which heats the cold water in the heat exchanger to the required temperature.This is how most gas boilers, such as Bosch, Vektor and others, work.

The design of modern heat exchangers is technically thought out. For example, in the gas column Neva Lux heat exchanger has a spiral coil shape. This allows you to quickly heat the water for its subsequent submission to the taps. All products of combustion are immediately removed from the room to the ventilation through chimney (although there are cheap models of the Chinese brand Vektor, which do not have such an outlet in their kit).

Gas column design

Symptoms for urgent cleaning column

There are several signs that should push the owner to the idea of immediately cleaning the unit:

- cotton when the burner is ignited (by the way, the popular “disease in Bosch WR 10-2B according to user feedback);

- the burner shuts off quickly;

- soot poured out from under the casing;

- water barely heats up at the maximum power of the device;

- from the crane there is a weak pressure of water (although, for example, the Avangard models can work fine with low water pressure).

You can fix the problems as follows:

- clean the jets;

- clean the igniter;

- remove soot from the heat exchanger;

- Rinse the gas column heat exchanger from the formed scale.

Each of the events held has its own characteristics. Do-it-yourself cleaning of the gas column implies an initial shutdown of the water and gas supply.

Why soot appears

Of course, it is ideal to call a qualified specialist, but often soot can be completely eliminated with your own hands. Especially when she scores nozzle openings - in this case it is easy to clean with a metal brush or thin wire. For example, users of Bosch WR 13-2P complain that the nozzles in this model are very quickly clogged, like the igniter (which is unpleasant at a decent price that the manufacturer asks for the device).

By the way, this is not the only problem with the igniter of the famous brand: for example, the Bosch WR 15-2P it often goes out for reasons independent of pollution. This problem should definitely be addressed to the service center.

Soot can create and gas leak. The user with this minimum gas does not take into account the dangerous smell. It is checked as follows: a solution of soap is applied to the joints of the pipes with a brush.Bubbles witness the problem - a gas specialist should be called in immediately.

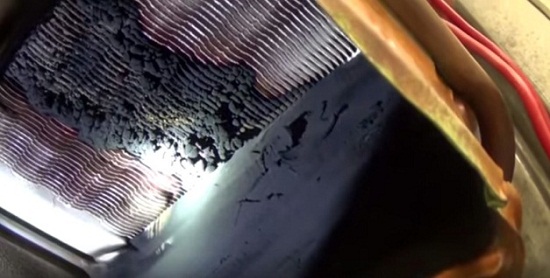

Dirty raditor - also a prerequisite for calling soot. Here a vacuum cleaner comes in handy: shut off the gas supply, remove the casing from the column and remove the soot that has formed. It also happens because problems with the load. The test is this: again, with the gas shut off, bring a lit candle, a lighter, or a match. Normally, the light will deflect or completely extinguish the flame. With a negative result, the chimney requires cleaning.

Here you can separately praise the range of units Therm 4000 S from Bosch, which has a forced-draft fan, eliminating such problems.

How to remove soot from the heat exchanger

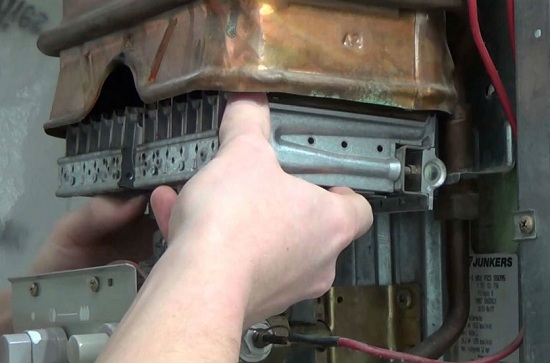

It is better to learn how to conduct such an operation on your own, because when a heat exchanger part fails, for example, from Bosch, the element is so expensive that it is much easier to buy a new column. To hold such an event, it is necessary to completely remove this detail. Before starting work, it is necessary to prepare a special aerosol agent for softening those threaded connections that have already become attached.The burner nozzles are covered with a cloth to prevent soot from getting there. Clean the heat exchanger is necessary for such a guide.

- The gas and water supply is shut off, and then the hot water tap closest to the heater opens.

- The cap nut is loosened with a gas or open-end wrench, which secures the pipe to the water unit. It will be enough to make two turns. Water should flow through the open tap - even if it remains in this state.

- For further dismantling, unscrew the captive nuts - now the knot can be easily pulled out. However, along with it, other parts are also removed. If you are not confident in your actions, it is better to turn to professionals.

- Dismantled parts are taken to the bathroom. Taking long pile brush and detergents, carry out the washing of the heat exchanger.

- Installation is in the reverse order. On the pipes you should definitely put new sealing rings.

- Before starting, be sure to do leak test. The water supply will fill the contents of the gas column heat exchanger. After closing the valve, the reliability of all connections must be checked. If there is no leak anywhere, you can open the gas valve and start the device in normal operation.

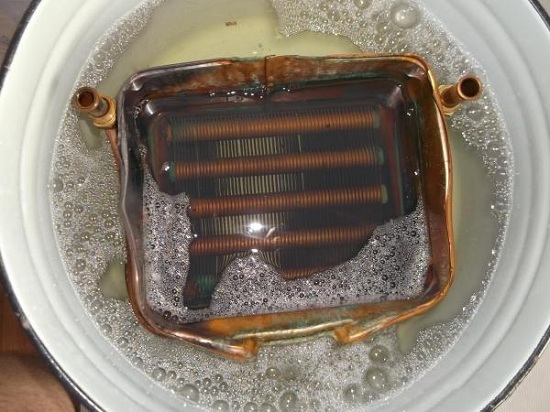

How to wash the heat exchanger from scale

Another procedure that can be carried out with the removed part, is cleaning the gas column from the resulting scale. Variations of cleaning compositions can be so much:

- ready from the store;

- prepared solution from citric acid (in the proportions of 100 grams of powder to 0.5 liters of water);

- acetic solution (9%) in the ratio 1: 5.

Further actions on how to clean the gas column from scale will be such an order.

- When using store tools, you must look at the instructions on the package.

- How to wash the gas column (heat exchanger) "popular" means? Everything is poured into the heat exchanger using a watering can. Now we need to leave to soak - for a few hours, but better at night. After that, the contaminated liquid is drained, and the part itself must be rinsed well under running water (preferably with a hose).

Such measures should be carried out annually, and not in case of emergency.

The option of cleaning the water intake unit

In this node there is a strainer that prevents the pipes from clogging with large pieces of rust and sediment. Important to check membrane tension - this detail by the automatic machine provides intake of gas at the included crane with water.

It is necessary to follow the following algorithm:

- Remove the node from the device.

- Unscrew the screw part, open the case.

- Clean the filter by placing it under a strong stream of water.

- Now it's time to check the membrane. Convex indicates the time spent - it is better to replace it with a silicone version.

- It remains to close the cover in the receiving unit, tightening the screws. So the membrane will stretch evenly.

So, if you need to clean the gas column, two important aspects must be taken into account: in gas terms, only the jet nozzles can be cleaned. For other cases, the intervention of a specialist is necessary. But with the piping component, you can work independently. It is only important to follow the rules and recommendations given by us.

/rating_on.png)

/rating_off.png)