Configure and troubleshoot carburetor chainsaws

The operation of the internal combustion engine (ICE) chainsaws is based on the combustion of the fuel-air-oil mixture. To mix the gasoline-oil mixture with air, and then in portions to feed it into the combustion chamber, a rather complicated device is created on the engines - a carburetor. When buying a chainsaw, the carburetor already has factory settings, but over time they get lost, and the device that controls the fuel supply needs to be adjusted again. Not knowing how the carburetor is arranged, and not understanding the principle of operation of this module, it will be problematic to correctly adjust it.

Content

The design and principle of action of the carburetor chainsaw

The carburetor chainsaw consists of and following main nodes:

- solid cast body made of lightweight aluminum alloy;

- a diffuser located at the entrance to the carburetor;

- jets, special valves designed to regulate the flow of combustible mixture;

- sprayer;

- float chamber.

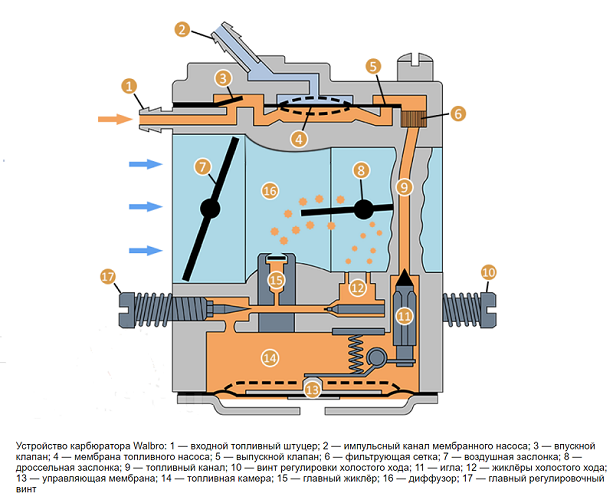

Below is a diagram Walbro carburetorwith which chainsaws are very often equipped. Using this scheme, you can examine in more detail the internal structure of the carburetor chainsaw.

The carburetor can have 2 or 3 adjustment screws with springs. The adjusting screws are designed so that their ends are needles (cones). The screws have a right-hand thread, i.e. they are screwed clockwise.

Work carburetor chainsaw occurs as follows.

- After starting the internal combustion engine opens the air damper.

- In the diffuser (16), where there is a narrowing, the air flow is accelerated and mixed with gasoline. The latter enters through the nozzles (15) and (12), and the air purified by the air filter goes through the flap (7) located at the inlet of the diffuser.

- The valve (8), located behind the diffuser, regulates how much of the prepared mixture enters the combustion chamber.

- The volume of gasoline passing through the nozzles is adjusted by screws (17) and (10) —the screws L and H on the chainsaw, respectively.

- The volume of the fuel mixture in the float chamber (14) depends on the needle valve (11). The function of the needle valve is controlled by a diaphragm (13).

- The membrane (4) controls the flow of the fuel mixture into the combustion chamber, and this depends on the number of revolutions of the engine. Gasoline is cleaned through the filter (6).

When adjustment is needed

As already mentioned, the new chainsaw already has the standard fuel supply settings. But for proper running it is recommended to limit the maximum engine speed, and this is done with the help of adjusting screws located on the body of the carburetor. Also, after running in, you will need to make a more accurate adjustment of the supply of combustible mixture.

In addition, the carburetor will have to adjust in the following cases:

- due to strong vibration, the factory settings were lost;

- ICE bad start and immediately stalls;

- ICE starts, but the momentum does not develop, and it stalls;

- the piston group has worn out - in this case, the adjustment of the carburetor of the chainsaw is possible as a temporary measure;

- the engine does not function at idle;

- increased consumption of gasoline, because of which the unit produces a lot of smoke, the muffler and spark plugs are contaminated by soot, the engine power is reduced.

Carburetor setting rules

You should know that the carburetor can be properly configured only if:

- cleaning filters (gasoline and air) are not contaminated;

- nozzles and channels suitable to them are clean;

- membranes are not damaged;

- the needle valve is in good condition and the required volume of the fuel mixture enters the float chamber.

To adjust the carburetor imported chainsaws, you must adhere to the following rules.

- Before adjustment, whenever possible, follows warm up the engine at idle or minimum speed about 10-15 minutes.

- Turn the “L” knob Achieve such work of the engine, so that it gives out at idle one and a half to two thousand revolutions per minute. But you should pay attention to how the engine is gaining momentum. When you press the accelerator lever acceleration should go quickly and evenly. If a “failure” of turns is detected, the screw should be slightly unscrewed until this phenomenon is eliminated,because it is caused by insufficient enrichment of the fuel mixture.

- When the mixture is adjusted at low speed, you should start tighten screw “T” until you notice the rotation of the saw chain. After that, the screw should be unscrewed in half or a third of a turn, observing the behavior of the clutch mechanism. Normally, at idle speed, the saw should not rotate.

Screw “H” compensates for low or high rpm due to the replacement of the type of fuel, changes in the concentration of oil or humidity of the surrounding air.

Also, the “upper” setting can fly off with an appropriate screw for incorrect adjustment of the low revs.

Screw “H”, not having enough experience, better not to regulate. If the setting of the carburetor of the chainsaw will be made by an incompetent person, there is a great danger that at high speed the mixture will be too lean to the combustion chamber, especially under load. Such an operation of the engine will inevitably lead to rapid wear of its piston system and failure of the ignition system.

You can begin to adjust the high speed, if the person who will perform the setting,has the knowledge and skills to adjust carburetor engines. At the disposal of the master tuner should be a special device - tachometer or multimeter with oscilloscope function.

Setting up the carburetor chainsaw, namely, high engine speed, occurs according to a simple scheme.

- It is necessary to tighten or unscrew the screw “H” until at maximum gas the engine develops about 15 thousand revolutions per minute (by tachometer) or the value indicated in the manual for this unit.

- When using an oscilloscope, the frequency of the spark discharge should be in the range from 230 to 250 Hz. It should be borne in mind that under load the frequency may decrease by approximately 10-15%.

It can be concluded that for safety, the internal combustion engine should be adjusted to slightly lower speed.

Chinese chainsaw carburetor should be set up on the same principle as described above. On its body there are holes in which, in order to regulate the engine speed, you need to insert a flathead screwdriver. Each hole is signed by one letter out of three. As a rule, you can see the letter “T” near the top hole, and the letters “L” and “H” near the bottom holes (shown by arrows).

The same arrangement of screws has the Chinese chainsaw carver (CARVER).The following figure shows what the carburetor looks like from a Chinese chainsaw outside the body of the unit.

How to troubleshoot the carburetor

The main problems with the carburetor chainsaw can be as follows.

- The engine starts up with difficulty and stalls a few seconds after the start. Often the reason for this is the incorrect setting of low revs. The fuel-air mixture is poorly enriched. It is necessary to unscrew the screw “L” half a turn, after which the adjustment should be completed with screw “T”.

- Engine power is significantly reduced under load. This means that the carburetor excessively enriches the mixture with oxygen. Therefore, the “H” screw should be tightened slightly, about 1/8 of a turn. If after such actions the engine power is still insufficient, but there has been some improvement in its operation, then the regulator can be further tightened.

- The engine at maximum speed and without load begins to sing. This failure of the unit causes a lean mixture and oversized turns. The adjustment is made with the same “H” screw.

- Gasoline does not enter the combustion chamber. Breakage may be caused by clogging of the fuel filter, channels and carburetor jets. To eliminate the malfunction, you need to completely disassemble this chainsaw module and blow its channels with compressed air (you will need a compressor). To efficiently clean the fuel channels, you can use a special carburetor fluid for flushing. Also, the lack of fuel in the engine cylinder may be due to improper adjustment. How this is done by hand is considered above.

- Pour over the carburetor. In 90% of cases, the overflow of fuel is caused by a dried and coarsened membrane, which presses on the rocker arm associated with the needle. To change it, you need to remove and disassemble the carburetor.

- The engine is not gaining momentum, it works intermittently, power is reduced. These problems often cause a clogged air filter. You will need to remove the cover that covers the filter and clean it, which consists of washing with detergent.

In general, timely adjustment and timely repair of the carburetor chainsaws can significantly extend the life of the entire piston system of the engine.Therefore, the configuration of this component of the fuel system must be treated with great attention.

/rating_off.png)