Why the air conditioner does not start when turned on

Many owners of air conditioners must have come across problems of a different nature. One of them can be attributed to the situation when the air conditioner does not turn on. The causes of this failure can be both serious and easily removable.

Content

Causes of the problem

This problem may have many reasons, the most common of which include:

- lack of tension;

- voltage instability;

- severe temperature drops in the room.

The first step is to produce power network check. Very often this is the reason why air conditioning is not working. The high temperature that occurs during the operation of the equipment, can quickly bring the insulation of the wires into disrepair.

Equipment grounding is an integral part of its operation.Otherwise, the use of equipment becomes life threatening.

Severe temperature drops can be a major factor in causing a situation when the home air conditioner does not turn on. A sharp rise in temperature can cause the expansion of the materials from which the air conditioner is made, which leads to its destruction.. Low quality split systems are made of materials that do not meet technological requirements and do not withstand temperature differences.

Compressor out of order

Identify failures in the compressor is not difficult. This situation is characterized by frequent failures, increased noise and oil smudges on the device. In case of malfunctions of this nature, it is recommended to contact a qualified equipment repair specialist.

One of the main causes of failure - refrigerant leak. The following factors can trigger a leak:

- cracks in the body;

- wear rubber, from which the gasket is made;

- line failure.

The presence of dirt, loosening the belt, and disrupting the power supply can trigger a breakdown.If you noticed in time that there were failures in the compressor, you can repair it. At later stages, there is one solution - replacing the part.

Frost on the split system - freon leak

Control panel malfunction

There are two types of remote control panels:

- mounted;

- wireless.

AT mounted remote troubleshooting is fairly simple due to the presence of an LCD display. If it stops working, it is necessary to disassemble and first check the voltage at the terminals. The presence of voltage characterizes the failure of the console, and its absence - the failure of the internal unit of the split system.

Check the normal operation wireless remote You can use the built-in camera phone. For this:

- turn on the camera on the phone;

- point the transmitter emitter to the camera;

- take a picture by simultaneously pressing any button on the control panel.

If the picture shows an infrared flash emanating from the radiator, then the remote control is in good condition. If not, the remote is broken and needs repair. If the remote control is working, and the air conditioner still does not turn on, it means that the breakdown lies in the reception board.

The failure of the receiving board is the most common reason why the air conditioner stopped working. Most likely, the cause of the malfunction was blown fuse.

When contacting a repair shop, be sure to specify whether the part will be repaired or completely replaced. In the case of complete replacement of the fuse price will be much higher.

If you have special electronics skills, you can try repairing the fuse yourself.

Crashes in settings

Each split system is equipped with a special self-diagnosis mechanism, which determines both the temperature of the room, and the optimal mode of operation to maintain the specified parameters. Failure in the settings - a frequent reason for which the equipment does not start.

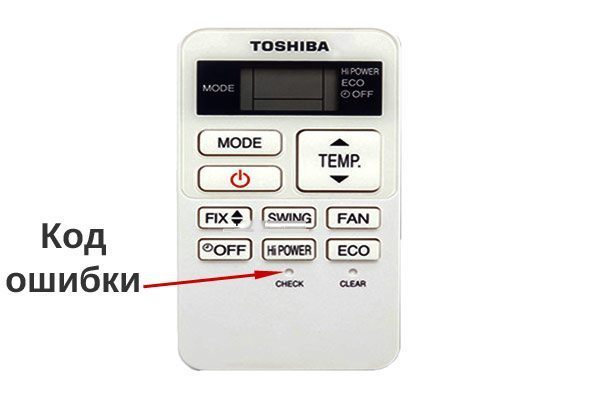

One of the signs of failure in the settings of the device is the appearance on the display of a special error code, the decoding of which you can find in the instruction manual. For example:

- code 1, decoding - failures in the temperature sensor;

- code 2, decoding - frosting of the evaporator.

Operation Tips

Below are a number of tips, following which, you can reduce the risk of breakage on your equipment.

- Produce regularly filter cleaning. Simply rinse the parts under running water, dry them and set to their original location.

- Watch for freon leak from the system. Even with a professional installation to avoid leaks will not work. This is due to the method of connecting pipes - flared, during which small cracks appear. The average rate of freon leakage should not exceed 7-9% per year.

- Pay special attention to the device. in winter. The minimum permissible operating temperature of the device is 0 degrees. When working in low temperature conditions, it is necessary to have a special unit that allows the equipment to operate in conditions of temperature difference.

/rating_off.png)