Using a drill as a screwdriver

Among the electric tool drill-screwdriver occupies a leading place, judging by sales. This is the most purchased instrument, since it is distinguished by its practicality and versatility: in one device they are combined immediately 2 units. It is a drill (for drilling holes) and a screwdriver (used for tightening and unscrewing screws), and sometimes a hammer drill.

Content

Types of drills

On sale you can notice the following feature: some tools are quite expensive, while others that perform the same functions are cheap.This fact is explained quite simply: there are tools for professional use, as well as for amateur (domestic).

Household tool the technical characteristics are significantly inferior to the “pro” class. It is intended for infrequent use, and then for a short time. On average, household drillers are used no more than 4 hours per day, in the mode: 15 minutes. work - 15 min. break.

In order to reduce the cost of production, the manufacturer uses parts of low quality or of fragile materials in such units (for example, plastic ones are used instead of iron gears). Yes, and the electric motor does not have a special power, and quickly overheats. The torque of household appliances is in the range of 15-20 Nm, and the rotation speed is up to 500 rpm.

Professional toolOf course, unlike amateur one, it has better characteristics, but costs more. Some drilling units with a screwdriver function have a torque of up to 130 Nm and a speed of 1,200 rpm. At the same time, they have a good cooling system and do not overheat during prolonged operation.

Drill-screwdriver device

The symbiosis of screwdrivers and drills is most often performed in the shape of a gun (see picture below).

The design of the unit is peculiar to the following elements (numbering corresponds to the figure).

- Housing In models of class “pro”, the case is usually made of plastic of special strength, resistant to shocks and tool drops. The interior of the device consists of an electric motor, a cooling system (air), control modules and mode switching.

- Lever. Has the ergonomic form for a convenient arrangement in a hand. Often the handle has rubber inserts to prevent the tool from slipping out.

- Battery. The battery may be of the type shown in the figure above, or hidden in the tool grip.

- Start Button. From the force of pressing the trigger depends on the frequency of rotation of the cartridge unit.

- Toggle Button directions of rotation. Located in a convenient location and allows you to easily and quickly switch between spindle rotation modes.

- Speed shifter. Usually it works in 2 positions (2 speeds): the first position (low revs) is used to operate the unit in the screwdriver mode, the second (high revolutions) switches the device to the drilling mode.

- Cartridge. A different working tool (bits, drills or special tools) is clamped into this unit element.

- Sponge cartridge.

- Ratchet - an element that allows you to adjust the force of the screwing screw (torque force). In order not to twist the screw, for example, furniture, set the required clamping force on the ratchet. When a certain effort is reached, the clutch slips and the tightening stops. This feature helps to avoid damage to the product. The range of regulated efforts can vary from 4-6 positions (in budget models) and go up to 20 or more in expensive devices. The controller also has a drilling mode, indicated by a drill icon, so that the working tool does not stop during this process. The presence of a ratchet is the main difference between the apparatus and the drill.

- Backlight. Some models of the class “pros” have at their disposal an element of the backlight. This is usually the LED located at the top of the handle. Such addition is convenient, for example, when assembling furniture, when it is necessary to perform drilling work inside the cabinet, where lighting is limited.

Types of battery drills

No matter how good the appliance is, without good batteries it’s hard to talk about its performance. It should be understood that the battery may have a cost of half the cost of the drill itself. Often there are cases when the drill-screwdriver is workable, but the accumulated battery leaves the owner of the device at a loss as the price for it is high. Also, some manufacturers do not sell this item, and it is often impossible to replace it. The only way out is to buy a unit with a battery that lasts a long time.

The main characteristics of batteries are capacity and voltage. Voltage is the main indicator that determines the power of an electric drive. The maximum rate of torque depends on the drive power. The market for electric tools represents screwdriver models with a working voltage of 9.6; 12; 14.4 and 18 V. More expensive units may have a voltage of more than 20 V, reaching 36 V. To use the tool for household work 14.4 V will be more than enough.

On sale you can sometimes see devices similar in appearance, but different in terms of voltage.

In this case, you need to take into account the fact that the battery is not interchangeable. If you put the 18-volt battery on the device, designed for a voltage of 14.4 V, then the electric drive will burn out in it.

Battery Capacity it is customary to measure in Ah (Ah) - in ampere hours. This indicator can be seen in the form of an inscription on the battery.

This value indicates the duration of the appliance without recharging, with a fully charged battery. Therefore, the larger the capacity, the less often you will need to put the battery on recharging.

Professional units need to have an element capacity ranging from 2 to 3 Ah. Household tools will be enough capacity from 1.2 to 2 Ah.

Batteries can be divided by the types on which their performance depends. Batteries are:

- nickel-cadmium (Ni-Cd);

- nickel metal hydride (Ni-MH);

- lithium ion (Li-Ion).

Nickel-cadmium (Ni-Cd)

This type of battery has a relatively low price, but is quite common in middle class devices. Despite the arrival of new types of batteries on the market, this battery was both popular and continues.

The advantages of this type of battery:

- low price;

- tolerates low temperatures during operation or during storage;

- full discharge of the battery does not harm it, so the tool can be stored in a discharged state for a long period, after which (with proper charging) it restores its properties.

The cons of Ni-Cd batteries are quite tangible.

- A battery capacity of 2 Ah is considered to be the limit.

- Short service life. The highest quality batteries do not withstand 1000 cycles (charge-discharge).

- High degree of self-discharge. If the battery is fully charged, then after a while you will find that it is fully or partially discharged.

- “Memory effect"- the biggest disadvantage of these batteries. You can not put the battery on recharging, if he has not exhausted the resources completely. This is explained by the fact that when trying to charge a battery not from a zero value, the value that remains in the battery will be perceived as “0”. Therefore, the battery capacity is reduced by artificial means. To prevent this from happening, before connecting the battery to the charger, it should be completely discharged. This fact causes inconvenience, since one has to waste time on the discharge procedure.

- Ni-Cd elements must be disposed of properly, otherwise they harm the environment.

Nickel Metal Hydride (Ni-MH)

This type of battery can be called an attempt by manufacturers to get rid of the shortcomings inherent in Ni-Cd elements.

Advantages of Ni-MN batteries:

- when recycling - harmless;

- the capacity parameter reaches 3 Ah;

- the consequences of the “memory effect” were reduced, but it wasn’t possible to get rid of them.

Disadvantages:

- cost higher than that of Ni-Cd;

- the number of recharge cycles does not exceed 500;

- high level of self-discharge (about 10% per day);

- at low temperatures capacity is lost;

- can not be stored charged.

Lithium Ion (Li-Ion)

This is the most advanced type of battery for use in power tools and not only.

Advantages:

- lack of “memory effect”;

- power density and capacity exceed the above battery;

- fast charge;

- low self-discharge;

- The “life” of the battery exceeds Ni-Cd 3 times.

Disadvantages:

- great item price;

- although the battery can be used at low temperatures, it will not be charged in the cold;

- it is impossible to allow a full discharge, therefore, a microcircuit is installed in the batteries, which does not allow complete exhaustion of the resource.

Often these batteries have an indication of the level of charge.

Network drill screwdriver

A power drill with the function of a screwdriver can also be suitable for those craftsmen for whom the power cord is not a hindrance. Since the electrical device operates on the network, it lacks the drawbacks of the units with batteries.

Of course, which is better: a networked electrical appliance or a battery - to judge you. The only thing to consider when choosing a drill-screwdriver is power cord length.

What to look for when choosing

Choosing a two-speed drill-screwdriver, you should clearly understand for what purposes it will be used, and with what loads it will have to face. Any master, whether it be a pro or a home craftsman, must have an idea of the main characteristics of the components.

Type of cartridge

Drill as a screwdriver can be equipped with two types of cartridges: quick-clamping and key. Keyless type the cartridge allows the master to easily change the working nozzles, which improves performance.

Key type Chuck implies the use of a special key for tightening the working tool in it. In this case, a quick change of drill or bit will not be available.

Punch function

Drills-screwdrivers often have the function of a punch.This means that the appliance, in addition to the rotational movement, is capable of creating a shock force. The perforator is used for punching holes in solid materials (brick and concrete). But it should be borne in mind that they use the percussion function of the apparatus only on brick or light concrete.. For drilling a reinforced concrete wall, of course, it is better to use a perforator as a separate type of electrical device.

The function of perforator are not only units that operate on the network, but also battery ones.

The figure below shows a cordless impact drill screwdriver.

Tool weight

A very important indicator is the mass that a screwdriver or drill has. When working at height it is recommended to use compact model drill screwdriver. If you intend to use the unit as a drill, then it will be better to behave an electrical appliance with a larger mass.

Drilling Accessories

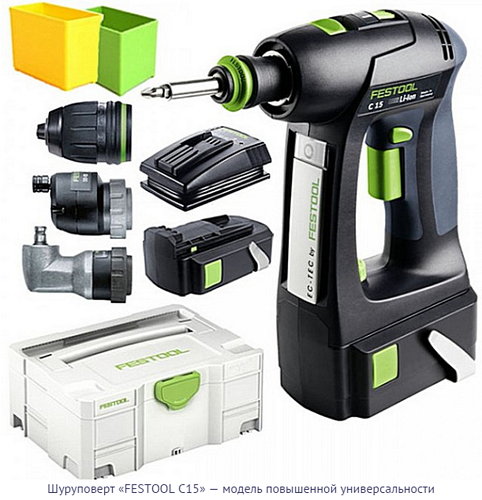

Devices of the class “pros” can have all sorts of attachments for the drill and screwdriver. These devices significantly expand the functionality of the appliance. Attachments to the drill can be different in purpose. The figure below shows, for example, an FESTOOL unit, model C15.

The device, in addition to the adapter for bits (hex), which allows to use the drill as a screwdriver, is equipped with a set of tools that can be worn on the drill-screwdriver. In the configuration can be seen corner nozzle for drilling and using the drill as a screwdriver at a 90 degree angle. There is also a nozzle offset center, allowing to perform work in the corner, in contrast to the usual cartridge, the shape of which does not allow to do it.

Thus, the drill-screwdriver differs from the drill with improved functionality, as well as different modes of operation, which, in turn, makes working with a tool for the home master and professional more convenient.

/rating_off.png)