Benefits of using a drill mixer for construction work

This product belongs to a specialized power tool, which is used for work in a particular area - the construction and repair of buildings. Drill mixer has no analogues in the preparation of the solution in small quantities, stirring putty or thickened paint. Its main advantage is that this tool can be used in different ways: in the mode of an ordinary drill or as an original mixer.

Content

Device and species

This tool consists of a powerful electric drill and special nozzleand sometimes two for simultaneous mixing. The drill can work in a large rev range.its parts are resistant to temperature effects, and in the arsenal there are various types of additional nozzles for quick preparation of different solutions.

It has a higher speed and solid power, which allows you to quickly cope with the tasks. The quality of any kind of solution is many times higher than a similar batch made by hand. Many water-based solutions are used in construction, and they need to be mixed very thoroughly for a long time in order to produce a homogeneous pasty mass. When using a drill mixer, this happens in a matter of minutes due to the correct selection of revolutions and power.

Drill mixer happens single and twin screwThe second variant is distinguished by high productivity due to increased power; they can also be used to knead small portions of concrete. Nozzles rotate in different directions, like an ordinary kitchen mixer, while stabilizing the position of the drill itself. The high power of the tool allows you to knead more solution in one cycle - this is its main technical indicator.

Mixer construction Vitals-Master twin screw

Functions of the mixer mixer

Basically the mixer is designed for intensive mixing different solutions and viscous suspensions for construction works:

- acrylic based primers;

- paints that can be diluted with organic solvents or ordinary water, for example, for painting the facade of a building;

- mastic with bitumen;

- putty on polymers, plaster or cement;

- plasters of various composition;

- a mixture based on various adhesives, composite compositions for facing with tiles, outer tiles, mosaic of glass;

- concretes of various consistency.

In addition, the drill mixer can be used for the main purpose: to drill various holes in solid materials - concrete, brick.

The process of preparing solutions is as follows:

- dry mixture is poured into a deep container, then it is poured with water at the rate indicated on the package;

- the nozzle is lowered into the tank and the drill is turned on - mixing continues until a homogeneous composition;

- the solution is infused for a certain time so that all the components are completely dissolved at the molecular level, then mixed again and sent to work.

The volume depends on the capacity, but, as a rule, do not do more than 10 liters so that it does not thicken. The nozzle after use is washed with running water.

Drill bits

Different nozzles (many call them beaters) for a drill mixer have standard sizes:

- length - from 400 to 600 mm;

- diameter - not more than 160 mm.

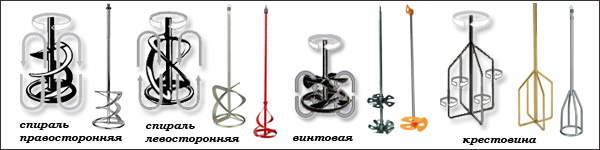

For different viscosities and features of the components of the mixture, different forms of the mixer are used.

Right-side helix

Such nozzles from quality steel or titanium have a diameter of 100-160 mm and are used for mixing heavy viscous mixtures:

- cement mortar;

- gypsum cement plaster;

- adhesive mixtures under the tile;

- mixes for a seamless floor;

- sealant, front putty;

- epoxy resin with filler;

- compound for casting.

Due to the special design, mixing occurs in a direction from the bottom to the top - the solution is captured from the very bottom of the tank and pushed to the surface.

Left-side helix

Its diameter has a smaller range - from 120 to 160 mm; it is used for mixing lighter and more flexible mixtures:

- various paints;

- varnishes;

- wallpaper glue;

- bituminous and light suspensions.

The process takes place from the top to the bottom, the spiral nozzles push the components of the solution down, and then the mixture is squeezed up along the walls. Below all these types of nozzles have protective ring, so as not to damage the delicate elements about the bottom of the tank, where the process occurs.

Screw mixer

This nozzle has two active screws with opposite rotation, it is used only for mixing light paints and varnishes. With a strong rotation, the bottom screw pushes the solution up, and the top screw - on the contrary, which provides a fairly high-quality mixing without spraying.

Sometimes use plastic blades mounted on a steel base, so as not to damage the inner surface of the container.

Crosses

This type of agitators, having four so-called shoulders made of round metal rods, is intended for mixing the components, which, when mixed, do not allow air to get into the air - different sealants, putty on plaster, adhesives, compounds. Thanks to the original design, mixing occurs in the same plane and within the composition, which excludes air trapping.

In addition to these basic types of nozzles, there are narrowly defined types that are used for thicker mixtures: on the basis of gravel-sand, polymer floors with fillers, mastics and solutions based on clay with a high viscosity.

The figures show the main types of nozzles-mixers for mixers and construction drills mixer.

Method of consolidation

Fastening of nozzles is carried out by various methods and directly depends on the model of the tool.

- Screw the nozzle into the hole of the spindle, but before that it is necessary to remove the cartridge.

- Insert into the cartridge with a size of 13, 16 mm, clamp the jaws to the stop or use the Morse taper.

- Use FastFix or QuickFix fast latching fastener

The first option becomes standard from all manufacturers A construction tool of this class is not the most convenient option, but it is easy to unscrew the attachment with a key, even if it was picked up by a fast-thickening mixture. This option is convenient because it is possible to use nozzles from other manufacturers on the drill, since they are unified.

Choosing a drill mixer

We pay special attention to the following model parameters:

- weight - for the house to 4,5 kg, for production from 7 kg;

- power - similarly up to 1050 W and from 1300 W;

- speed up to 1050 rpm;

- diameter of a neck of a spindle of 43 mm - the European standard.

Let us consider more important technical parameters.

Power

The construction mixer has an electric motor whose power is measured in kilowatts - the performance of the drill depends on it.

- TO household seriesdesigned for home use, applies to tools with a capacity of not more than 1 kW - these are standard drills, rotary hammers and small-sized mixers.

- Builders and plasterers use tools with power above 1 kW. And the mixer drills for professional application have a capacity of 2.5-3 kW, which is quite enough for the preparation of the required volume of solutions in one cycle. They can work with heavy, very viscous mixtures.

Drill mixer can be used in a wide range of capacities, so experts get its most powerful option - reversible, so that it can be used without restrictions.

Weight

A drill for domestic work has a weight of no more than 2 kg, perforators and percussion variants - 2.5 kg, more powerful ones - up to 10 kg, and construction mixers have a mass in the range of 7-15 kg.This weight is necessary for sure mixing of a large amount of mortar, especially when two nozzles are mounted on the drill at the same time.

Adjustment of turns

The professional tool has a built-in electronic module that allows adjustment of the armature speed of the electric motor, which is necessary during intensive mixing of various mixtures. When water is added to dry mixtures, all their components immediately interact, resulting in a completely different and rather complex composition, where the viscosity begins to prevent the mixing of heterogeneous particles and the stable operation of the tool.

The mass of the mixture also affects the operation of the engine, providing resistance, resulting in turnovers decreaseand the electronic controller prevents this and maintains a constant optimal mode. As a result, the tool works in one mode and brings the solution to the desired consistency, despite the mechanical resistance of the mixed medium.

All professional drills-mixers are equipped with such a stabilizer of the motor speed.

Well, if the drill will have additional functionality.

- Start smooth and emergency shutdown.

- Double insulated housing with overload protection.

- The rotational speed is controlled automatically.

- Additional handles with rubberized surface.

- Related parts: key for fastening the cartridge, stand, adapter.

Powerful construction models of cases for transportation do not have because of the large size, but covers for nozzles are attached to them, and it is convenient to transport them in the trunk of a car or truck body.

Today, on the shelves of stores you can find almost any model of the drill-mixer from leading manufacturers from around the world - branded from the company Bosch, many companies from China. Among them there are excellent specimens of domestic production.

Exploitation

During the use of the tool, it is necessary to adhere to safety measures and to comply with all the requirements of the manufacturer specified in the attached instructions.

- Never overload a drill and do not overheat its details, even in the case of embedded security systems.

- Use the tool only for its intended purpose.

- Comply with all restrictions set by its manufacturer, use the allowed speeds when drilling or mixing solutions.

- Protect tool from moisture ingress and mechanical external damage.

If you follow these simple rules accurately, the drill mixer will work for many years, helping you to carry out cosmetic or major repairs in an apartment or a country cottage. For professional builders, it is an indispensable assistant, with him all the processes of interior finishing will be carried out much earlier than the plan.

/rating_off.png)