Scope of application and choice of diamond drill

Drill - a tool that can be found in almost every home master. It is used to create holes in a solid surface, such as a concrete wall. For everyday needs, an average power device is enough, but if more serious work is to be done, you should pay attention to the drill designed for diamond drilling.

Content

What are the advantages

A diamond drill is definitely one of the most highly efficient tools for making holes in strongest materials. It is used for making recesses of different diameters in materials such as:

- reinforced concrete surfaces;

- brick walls;

- natural stone.

A diamond drill is different from its “colleagues” by the presence of a special diamond crown.

Different and her principle of operation. Conventional drill, as a rule, acts immediately over the entire surface, but in our case only a thin cutting edge is used. This allows you to significantly reduce the level of noise produced, reduce friction, reduce dust generation and achieve improved performance. Holes made in this way are smooth, with perfect edges.

History of use

Initially, a diamond drill was developed for mining industry. It was assumed that it will be used exclusively for the creation of tunnels in the rock. The crown of such a drill belonged to the class of deep drilling, and had the opportunity to be extended by additional pipes. A similar principle was later transferred to the construction industry.

Speaking about the construction site, it is necessary to clarify that it has become very recently to use a drill for diamond drilling in it. Tasks that fall on the diamond crown during repair work:

- the creation of a channel for gas and technical communications;

- formation of a trench during the laying of electrical networks;

- cutting out niches for sockets, etc.

Diamond Crown Configuration

Diamond crowns of a new generation have not changed much since their creation. As before, the main elements are:

- cylinder part with a connecting piece, the so-called shank - it is intended for connection with drilling equipment;

- the main cutting edge - fixed diamond segments.

There are cylinders for particularly delicate work, in which the sputtering covers the edge with a continuous layer. They are designed to work on:

- ceramics;

- tile;

- shingles and other fragile materials.

The diamond layer on the drill bit provides protection and, consequently, savings during operation.

The new generation allows replace worn segmentsAs a rule, this procedure is difficult to carry out at home, so the owners turn to specialized centers. Such innovations seriously reduce the average market cost, since a small segment is to be replaced, and not a whole cylinder. The body of the crown is practically not subjected to mechanical stress, and with proper handling it can serve for many years.

What to look for when choosing

When choosing a tool, pay special attention to type of shank. The main part of manufacturers make it suitable for all types, universal. It can also be equipped with a set of adapters.

If you have a standard diamond drill, then a crown, the diameter of which does not exceed eighty millimeters, is best suited.

The tool for other cases is selected specifically for a specific type of work. Experts advise to pick up a drill from the same manufacturer as the crown - this is due to the greater compatibility of parts. All tests and measurements are made by the manufacturer with their own equipment. Therefore, the use of the crown and drill from different companies can lead to results that go beyond the instructions.

The final decision on the choice is to take, referring to the amount of work to be done. A standard crown will suffice to create several small holes. And when doing construction work on an ongoing basis, it is worth thinking about acquiring professional equipment.

Famous manufacturers

Choosing a tool for the job, it will not be superfluous to get acquainted with the list of the most famous manufacturers of diamond tools.The following brands have proven themselves in the global market as producing reliable equipment for construction work.

AEG

One of the famous representatives is the company AEG, founded in 1887 by Emil Ratgenau. The company manufactures parts for both industrial drilling, oriented at the laying of deep tunnels, and for minor construction works. Crowns from this company are compatible with the tools of most manufacturers. This was achieved through the use of special adapters - Fixtec. The same system allows you to quickly replace the tooling, without the use of additional tools. Adapters are divided into two subspecies:

- with dust removal system;

- standard kit.

The elements are made using sintering technology, the main part of crowns belongs to the class of universal ones.

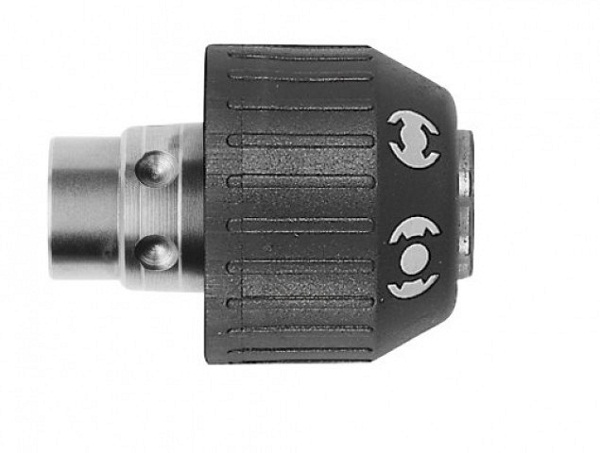

AEG chuck adapter

Bosch

Crowns from this solid company are produced using two innovative technologies at once - sintering the diamond edge segments and plating using galvanism. Pointed edge shape gives extra comfort and ease of operation.Improvement gives greater stability to the drill and significantly increases the speed of work.

One of the main distinguishing points of the crowns of the new generation is reduced vibration. The manufacturer presents several types of cylinders:

- wet drilling;

- dry drilling;

- for standard works.

Diamond crown Bosch Dry Speed 68 mm

In addition to the main collection is available:

- extension;

- a variety of fixtures for fasteners;

- additional systems of exact installation during handwork;

- special adapters for fluid supply;

- Dust suction heads.

It is possible to “renew” the segments by means of a grinding stone, as well as a storage tank of ten liters, supplying liquid under pressure.

Cedima

One of the most reputable companies in the market of construction equipment, actively promoting diamond drills. Cedima successfully exports its products to dozens of countries. Unique technologies in the manufacture of the drill allow him to go deep into the rock by five meters.

A wide range of specialized tools can satisfy the needs of both private enterprises and large organizations - there are manual units for dry drilling and massive complexes of drilling trailers in the range.A special system for the selection of segments, the synthesis of suitable diamonds with a given configuration of faces makes it possible to process almost all known solid surfaces.

Diamond Cedima Crown

HILTI

One of the leading places in the construction equipment market belongs to this company. Founded in 1941, it still develops and implements the concepts of new diamond crowns. The real pride of HILTI is unique principle of high-speed crown rotation, derived by the best engineers of the enterprise. Built on special principles, the system facilitates work with any material. The secret lies in the mechanism of pressure distribution. By feeding it selectively to individual diamond segments, the system forces them to work more efficiently. At the same time, the rotational speed of the cylinder can reach eight thousand revolutions per minute.

HILTI drilling rigs are compact and have increased productivity. Their use is relevant for a large amount of work.

SPLITSTONE

Russia is also not lagging behind its foreign colleagues in this race and has been successfully taking its place in the market since 1997.Splitstone develops and manufactures diamond tools using De Beers powder elements.

When repairing equipment, one of the most advanced methods is used - induction sealing. This method of restructuring damaged segments is recognized as the most gentle in temperature effects. Man-made diamonds are carefully processed, carefully returning to their original form. Russian equipment is famous for its reliability and adaptability to the conditions of our country.

Diamond drill 037x16x3x7x5x300 Splitstone granite

Conclusion

It can be concluded that a diamond drill is a very effective construction tool. Of course, its use requires certain skills, because the device has recently started to be used in our country, but the emerging prospects overlap the learning routine. Get familiar with the management of the unit, and you will not regret the time spent on it.

/rating_on.png)