Features of the use of a flexible shaft for a drill

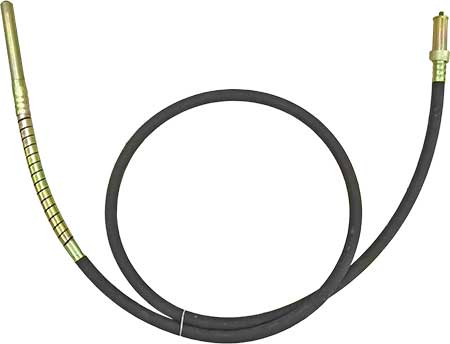

Each flexible shaft for a drill has high torsional stiffness and much less when bent. The main task of this part is the transfer of torque to rotating parts that change their spatial configuration during operation.

Design

The flexible shaft for a drill can easily bend in any direction. This was achieved with the help of a special structure:

- in the center is the core;

- outside a dense layer of wire.

Each wire layer consists of several veins, the direction of winding which alternates with each other. At the very end, a rigid seal is a cartridge or reinforcement. The shaft is covered with a special sheath that holds the lubricant and protects against mechanical damage.

This part can have both right rotation and left. It is designed specifically for work in various conditions.

Using

Such a drill attachment performs an important function, because shaft rotation speed depends directly on the type of work performed by the tool used. For example, procedures for cleaning surface corners, grinding plastic parts and polishing are performed with a nozzle at a low speed. Conversely, sharpening, cutting and other procedures that do not require delicate handling are performed at maximum speed.

In addition to the features already described, the nozzle in the form of a flexible shaft can be improved with additional details. So, for example, there is drive shaft with vibrotipused for work with concrete mixtures. The length of the nozzle can reach one meter, which allows you to interact with large volumes of the mixture. Use this device for compacting concrete:

- vibrotip immerse to the required depth;

- nozzle generates vibrations transmitted to the entire composition;

- vibrations expel the air that has accumulated in the concrete, which leads to its compaction.

Such shaft of the drive with vibrotip is used in construction works when creating foundations and solid concrete foundations.The use of technology requires some skill, but the effect is more than worth the time spent on training.

When buying this device, pay attention to its parameters:

- the diameter of the vibrotip may vary; the optimum value is thirty-five millimeters;

- shaft length is selected individually, depending on the specific work.

The shaft can be selected for any model of drill; contact a specialized tool store for a purchase.

Gear problems

The use of the vibrator head makes life easier for builders, but this procedure is not as safe for the tool as it may seem. From constant vibrations can jam such an important detail as the gear. This small element is located in the drill chuck and is responsible for its rotation. It is the gear in the final stage that the drill is set in motion and the drilling is carried out.

In the event of a malfunction, the work process stops, and further operation is not possible. In this regard, a logical question arises: "how to remove the gear, if it is planted on a hot one?".This is quite a difficult situation, because this method of packing does not imply the removal of individual parts from the shaft. Easiest buy a new cartridge or use the services of professionals. But especially for home craftsmen there are several ways to repair themselves.

First way

This is a complex method that requires some skill. This instruction is considered the most effective way to solve the problem. You will need special equipment and an adequate supply of free time:

- put a special puller on the cartridge, hold it tight;

- cool the shaft with carbonic acid;

- tighten the puller screw as far as it will go;

- Carefully handle the crown of the rod with boiling water, while not falling water on the shaft itself;

- select a heavy hammer and swipe the screw head on the puller;

- after that the gear will move a little;

- Apply a layer of graphite grease to the place of contact;

- continue to operate the puller as usual until you have removed the gear.

Second way

This method will also require tools and liquid nitrogen application:

- cool the shaft with the help of a reagent, do not fall on the gear;

- wait until the shaft shrinks in temperature;

- Using a hydraulic press, gently press out the gear.

The procedure should be carried out with extreme caution, because the treatment with liquid nitrogen makes the metal brittle.

Experts recommend not to complicate the process and simply cut the damaged part off the shaft. In addition, not everyone has at hand the sophisticated equipment for the precise manipulations described above.

A flexible shaft for a drill is a useful and convenient acquisition that contributes to the implementation of complex work. When buying, pay attention to the quality of the materials used in the manufacture, and the manufacturer.

/rating_off.png)