Which Bulgarian is better to buy for home or professional use?

The grinder is popularly called the angle grinder (angle grinder). This name appeared in the Soviet Union, when the only supplier of this tool was Bulgaria. But the name “grinding” does not fully reveal the possibilities of this device. With the help of angle grinders, you can cut brick, metal, stone and concrete, it easily turns into a grinding or polishing machine. All these changes are possible thanks to replaceable nozzles, which are fixed in the spindle of the unit. How to choose such a multifunctional tool?

Content

What are the types of Bulgarians

Bulgarians are professional and domestic. But this division can be considered somewhat generalized, since there are such angle grinders on the market, looking at which, it is difficult to give an unequivocal answer to which class they belong.

Household grinders

The main difference between professional and household tool is the duration of continuous work.. For example, devices for home use are designed for a short time (10 minutes) with intervals of 15-20 minutes. In general, such a Bulgarian should work no more than 2-3 hours a day.

The positive side of this tool is low price If you intend to use the device occasionally, for minor household issues, the household angle grinder will be the best and inexpensive choice for the home wizard.

Professional tool

The main disadvantage of a professional tool is its high cost.Also, the pro-class angle grinders have more weight in comparison with household models. But all these shortcomings are compensated by the continuous and uninterrupted operation of the device throughout the day, especially if constant use of this tool is required.

There are also semi-professional models of LBM and industrial. The latter are used to work around the clock and are used in enterprises.

LBM selection options

Before you buy an angle grinder, it is recommended that you familiarize yourself with the basic parameters of this tool. This will help you choose a device with optimal technical characteristics suitable for the type of work that you intend to perform with angle grinders.

Power

It is not difficult to guess that the more power a motor can produce, the more forceful the tool will work, and the stronger and thicker materials it will be able to cut.

An increase in the power of the apparatus inevitably leads to an increase in its weight.

The industry produces angle grinders with a power range from 0.5 kW to 2.7 kW. For home use and cutting thin materials, tools up to 1.2 kW will suffice.Accordingly, for cutting durable and thick materials it will be necessary for the grinder to have a capacity in excess of 1.2 kW.

Working disk size

The depth at which it can plunge into the workpiece depends on the diameter of the cutting disc mounted on the angle grinder. The thicker the part, the larger the diameter of the disk will be required.

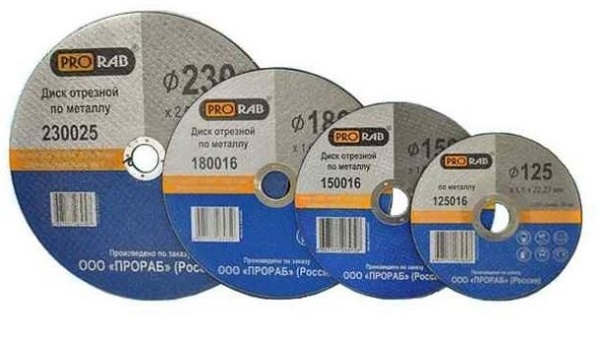

Manufacturers produce grinders of different sizes and different capacities, and these parameters determine the maximum size of the disk, which can be installed on the machine spindle. For angle grinders, discs and nozzles are produced in 5 standard sizes.

- 115 mm. This mini disk is well suited for cutting plastic, slate, thin-walled pipes made of metal, thin sheet metal. Also, a disc of 115 mm can be used for grinding and other minor works.

- 125 mm. Discs of this diameter, and, accordingly, angle grinders intended for them, are the most common for homework. Therefore, the sale of the largest range of circles with a diameter of 125 mm for these devices. They are suitable for cutting tiles, pipes, stone, slate, metal rods, as well as for polishing and cleaning various surfaces.

- 150 mm. They are mainly used for cutting concrete, steel and stone. For grinding small parts to use them uncomfortable.

- 180 mm. Often used in construction work for cutting stone and concrete, ceramic tiles, thick metal pipes, reinforcement and bricks. They are not used for grinding, as the weight of the apparatus is too heavy for this purpose.

- 230 mm. Used to perform rough construction work, for cutting heavy materials: concrete, brick, artificial or natural stone. Also with the help of the grinder with a disc of 230 mm it is possible to cut thick metal pipes, channels and boards of any diameter.

If the maximum allowable disk size is indicated in the instructions for the unit, then this device can be fitted with disks of smaller diameter. For example, if the maximum size of a snap for a specific model of the device is 180 mm, then you can put a tool from 115 mm to 180 mm on it.

Disk rotation speed

The speed of rotation of the disk mounted on the grinding machine directly depends on its diameter. The larger the diameter, the slower the rotational speed required.

The speed with which the LBD disk rotates can vary in the range from 2800 to 11000 rpm:

- for disks of small diameters (115 or 125 mm) a maximum acceleration of 10,000–11,000 rpm is allowed;

- for discs of size 150-180 mm, the speed is already limited - no more than 8500 rpm;

- for large circles of 230 mm, rotation is limited to 6650 rpm.

All speed limits are not random. Research experts have shown that the speed of the disc edge (linear) should not be higher than 80 m / s. Otherwise, the probability of destruction of the disk is high, which can lead to user injury its splinters. Therefore, be serious about how many turns you expose on the grinder for a specific tooling.

Handle type

LBM come with one or two handles. The passport usually indicates that the device has either a short or a long handle. Small grinders for discs of 115-125 mm usually have one removable handle. The user has to while holding with one hand to hold the handle, and the other - for the body of the device. The photo below shows a single-handle angle grinder.

If the tool has long gripthen on the back of it you will see an ergonomic holder, in which the hand comfortably fits. In addition, in this place there is a start button. The following photo shows a grinder with a long handle, that is, with two holders.

Therefore, it would be better if the devices with discs over 125 mm will have an additional rear handle.

Also of considerable importance is the availability of places for attaching an additional handle, as shown in the following photo (numbers from 1 to 3 indicate the attachment points of the holder).

Thanks to the ability to rearrange the handle, you can use the tool in different positions, depending on the location of work.

It will also be good if the rear handle will be able to rotate around its axis.

Profi angle grinders are often installed vibration damping handles. Their use significantly reduces the fatigue of the user's hands during long-term work. In addition, the reduction of vibration prevents the occurrence of occupational diseases associated with it.

Type of power tool

By type of power grinders differ on the network and battery. Devices powered from the electrical networkThe most common among owners of angle grinders. They have good power, develop high speed, and are able to work for a long time.

Professional and domestic types of Bulgarians are complemented by wireless devices powered by batteries. LBM on battery attracts with its portability. But such a tool can only be used as an auxiliary, for example, in the country, in places where it is impossible to connect to electricity, etc.

To perform complex, energy-intensive work (cutting of thick metal, stone, brick, etc.), a rechargeable angle grinder will not work. Its battery can withstand only 30-60 minutes of work with small loads (grinding, cutting bolts, cutting plastic, etc.). If you try to cut a thick metal battery, it will sit down in 5 minutes.

Additional Bulgarian options

Manufacturers of angle grinders have provided a number of additional options that can improve the performance of devices and can improve the safety of the user. Below is an overview of some of these options.

Smooth start

When you start an electric motor, the load on its winding increases in steps in a 6-8 times. This fact often disables the engine, and at best, protection is triggered when starting. Also with a sharp start appears shock momenttransmitted to the gearbox and spindle.

To eliminate this trouble, some manufacturers of angle grinders install a special electronic circuit capable of providing a smooth engine start. Due to the fact that the electronics gradually increases the voltage on the windings of the motor for a certain period of time, the rotor speed increases as smoothly.

Adjustment of turns

Not all angle grinders are available with speed control. Adjusting the speed of rotation of the spindle using the wheel placed on the device.

Adjustment of revolutions may be required when changing the tool diameter or when performing grinding work. In the latter case, the speed must be reduced. But if cutting of materials is required, then this should be done at high speeds, otherwise the tool will wear out faster and in some cases will simply break.

Electronic Stabilization

When a disc touches the workpiece, friction occurs, which significantly increases the load on the electric motor. As a result, the frequency spindle rotation decreases. To avoid a drop in engine speed under load, a system for stabilizing the speed is installed. Thanks to it, the number of revolutions of the spindle is maintained at the same level, despite the changing load on the tool.

Not all models of Bulgarians are equipped with this system, therefore its presence is rather desirable, but not necessary.

Automatic balancing

Since the tool attached to the grinder rotates at high speed, the slightest unbalance can cause beating and vibration. In expensive models of angle grinders, a special balancing mechanism is installed, which reduces vibration and beating, if the tooling is worn unevenly.

Anti-jamming

This protection is very important because when the tool is jammed, for example, while cutting a thick material, the motor winding starts to heat up and may burn out. Therefore, a good angle grinder should be protected from jamming. As soon as the motor rotor is forced to stop, the electronics are activated and the current is applied to the motor winding.

Re-start protection

The system of protection against restarting the engine will be useful in the case when during operation of the unit suddenly electricity is turned off. Even if the start button will be locked down, the angle grinder will not turn on when power is restored. To resume work, you need to loosen the lock and press the start button again.

Quick release clamp

With frequent changes of equipment on the grinder it can be very inconvenient to use a standard nut, which is unscrewed with a special key. Sometimes this procedure takes a few minutes. Therefore, when performing large amounts of work, with frequent tool changes, it is recommended to purchase quick locking nut SDS. With its help the equipment changes in some seconds.

Spindle brake

This feature is useful for people saving time. If you often use an angle grinder, and after turning it off, you don’t want to wait until the toolbox stops to put it on the table, choose a machine that has a brake device in its design.

In some Bulgarians, the brake works by the principle of frictionas in the car.But, for example, in Bosch devices, this function is implemented using a complex electronic circuit, and works on the principle of polarity reversal. But such a brake system works only when the device is connected to the network. If you pull the plug out, the spindle will not brake.

Electronic braking can be useful when jamming a snap into parts, and prevents the grinding machine from pulling out of hands.

Tips for choosing a grinder

Bulgarian is a tool without which the home master can not do. The scope of its application, as mentioned above, is enormous. Thanks to a large number of nozzles, the Bulgarian gets almost universal properties.

The prices for this device vary considerably. The pricing is influenced by the additional functions built into the unit, as well as the power of its engine. In addition, prices for household angle grinders are significantly lower than for similar devices intended for professional use. In order not to overpay money for unnecessary, additional functions that are not very important for low-powered grinders, it is worth deciding where you are going to use the grinder,and for what purposes: for home or as a professional tool. And after that, opt for a specific model of the device.

Bulgarian for home

If it is required to cut a bolt or a pin in any mechanism, cut a pipe of small diameter or dissolve a sheet of plastic (thin metal), as well as perform other minor works, then a medium-sized household grinder is ideal for this purpose. On average, the disk diameter (maximum) for such a grinder is 125 mm. By purchasing such a small angle grinder, you can do all the small work, including cutting, polishing and grinding.

For cutting thicker materials (brick, concrete), as well as more durable (ceramic tile, thick metal), semi-professional models can be purchased, with more power and the ability to fasten larger diameters to them.

It is necessary to take into account the fact that the household tool, if you look at the parameters, in many ways does not reach the professional level, and it should work for a short time (10 minutes), with interruptions for cooling the engine (20 minutes).

Grinder for professional use

If you are engaged in construction at a professional level, then you will need a professional angle grinder, without which you just can not do. For example, when building a house sometimes you have to often use the possibilities of angle grinders for various reasons. And wait until the home appliance cools down, just no time. In addition, household grinders when exceeding the standard in the work and overheating often fail. Therefore, you will do the right thing if you spend one time and get a class of "pro" with whom you will not have problems.

Professional angle grinders have slightly larger dimensions than domestic ones, allow you to perform various jobs all day long, without pauses on rest, they are distinguished by high power and the ability to install a snap-in of a large diameter - 230 mm and more. In addition, these devices have many protection levelsdiscussed above. Thanks to them, the risk of injury is significantly reduced.

/rating_off.png)