What are the cutting discs for grinders

The main tool for grinders are cutting wheels. It is no secret that the quality and speed of the work done depends directly on the correct selection of consumables. Therefore, before you go buy a disc for grinders, it is recommended to familiarize yourself with the main types and characteristics of consumables.

Content

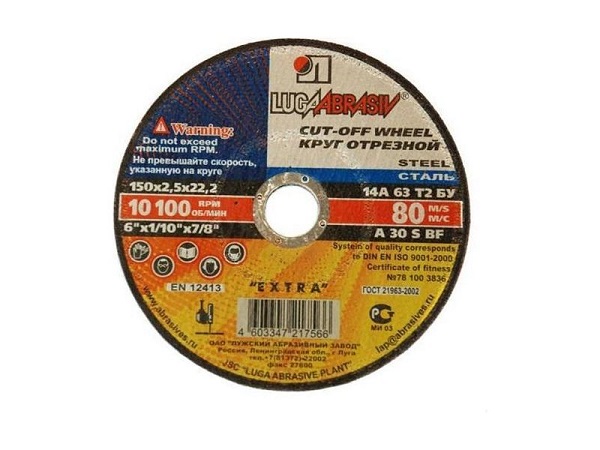

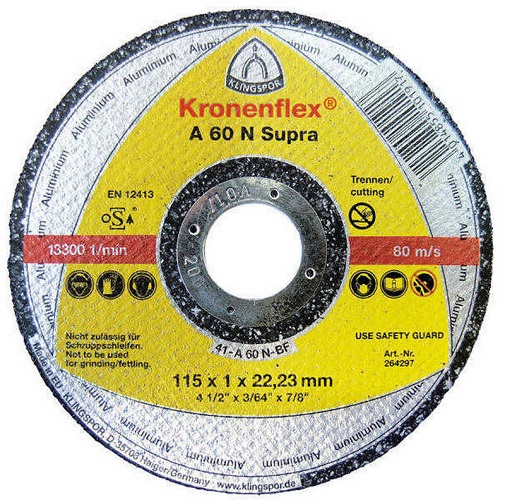

Marking on cutting discs

In order for owners of Bulgarians to choose the right consumables in accordance with the upcoming work of this tool, manufacturers of cutting discs put special markings on them.

Abrasive discs

The following information can be obtained from the marking.

- Material of which the nozzle is made, denoted by the first letter: A - corundum, used for cutting metal; AS - electrocorundum (white), cuts stainless steel; C - silicon carbide, cuts stone and concrete well. Metal using this abrasive nozzle can not be cut.

- Further, after the letter denoting the material, there is a number. It means how much abrasive grains is in unit area. Accordingly, the smaller the grain, the larger the figure. If you need to cut steel, then choose a disk with a grain smaller - 40 or 60. Coarse-grained disks are mainly used for cutting non-ferrous metals.

- The next parameter is ligament hardness. Denoted by the letters of the Latin alphabet (H, I, J, K, L, M, N, O, P, Q, R, S, T). The closer the letter is to the beginning of the alphabet, the softer the bunch, and vice versa. For processing soft materials, the bond must be hard, and for strong and hard materials, soft.

- The last letters mean ligament type. Ceramic is marked with the letter V. Such discs are characterized by good water resistance, fire resistance and resistance to chemicals. The bakelite bond is designated by letter B. Such circles have good durability at a bend and compression, but collapse when using a cooling liquid with an alkaline medium.Also binder based on bakelite have low heat resistance. At a temperature of 200 degrees, it becomes fragile, and at high temperatures it starts to burn out. The third type of ligament - bakelite with increased strength - is marked as BF or BU.

- Max speed, which can not be exceeded for this consumables. It may indicate the linear speed of the edge in m / s or in revolutions per minute.

- Circle size in mm: outer diameter, thickness and diameter of the seat.

- Date of manufacture. Usually indicated on the metal insert located around the bore. Installing an expired circle on the grinder is not allowed, as it can lose strength over time and scatter during operation.

- Nozzle designation. Specifies which materials the tool is intended to cut.

- Color coding: for cutting steel, blue is used, for cutting stone - green.

Color marking diamond discs

Diamond wheels are marked with the following colors:

- orange - for cutting bricks;

- blue cuts concrete and marble well;

- green is used to cut granite;

- gray cuts tiles, granite and ceramics;

- yellow - alabaster and tile.

Varieties of cutting discs

Cutting discs for the angle grinder can be either of abrasive material or all-metal. Depending on the type of material being processed, the type of cutting disc is selected.

On metal

If you want to cut the metal, then always use consumables on a bakelite bond with the presence of reinforcing elements. At the same time there should be no less than 2 reinforcing meshes.

For ferrous metals ordinary corundum is used, which contains, in addition to aluminum oxide, chlorine, iron and sulfur impurities.

For cutting stainless steel, the presence of the above impurities in the cut-off wheel is unacceptable, since they cause steel to become burned (overheating). As a result of this, stainless steel may burn out alloying additives, and it turns into ordinary steel, as a result of which the cut point begins to become covered with rust. Therefore, it is important to carefully read the information on it before buying a disc. The stainless steel cutting disc is always marked with the letters “AS” and the word “INOX”.

For cutting non-ferrous metals used discs with large particles of abrasive.For example, a cutting wheel for aluminum, except for a large abrasive, is composed of special fillers that prevent clogging of the cutting edge.

Often, users of angle grinders are wondering: which metal cutting discs are best to use? The ideal disk for the grinder should have:

- bakelite reinforced bundle (CU);

- correctly selected type of abrasive: for stainless steel white electrocorundum (AS), for ferrous metal - ordinary corundum;

- disc thickness from 1.6 to 2 mm;

- outer diameter 125 mm;

- small fraction abrasive particles, if cutting of steel structures is required.

For cutting sheeting It is not recommended to use abrasive wheels, because the cut point overheats, and zinc burns out of it - the main element that prevents corrosion. To reduce the overheating of the material, some craftsmen use a circular metal disk for the grinder with fine teeth. But in both cases, the cut point must be treated with a special anti-corrosion compound, which can be purchased at a store that sells profiled metal sheets.

For cutting stone

For cutting stone in the domestic environment suitable abrasive disc made silicon carbide (marked with the letter C).

This cutting disc is used for small works on stone, because it wears out quickly. But, due to the low cost, this consumables is quite popular with the owners of the Bulgarians.

For professional use, an abrasive disc for stone is not suitable. For these purposes, it is recommended to choose a diamond-coated all-metal cutting disc.

On concrete

Disks for cutting concrete and reinforced concrete are made from high-strength hardened steel, with diamond chips applied to the cutting part. Also, these cutting wheels can be segmented and solid.

Before you start cutting concrete, you must determine its type. It can be plain or reinforced (containing metal mesh). Also worth considering age of concrete.

- Young concrete has abrasive properties, so it quickly wears out the tool. For its cutting it is required to use diamond segmented discs on concrete of increased thickness.

- Old concrete is a very hard material. For its processing is better to use a circle on the grinder of moderate thickness.

For cutting reinforced concrete establish a universal diamond wheel.

For cutting tiles and porcelain tiles

It is best to use solid diamond cutting wheels for cutting ceramic tiles.. These discs are usually written “Wet cut". As practice shows, this tool remarkably makes an even, with a minimum of chips, a cut on the tile even without the use of water, although this produces a lot of fine dust.

Solid diamond disc can also be used on porcelain stoneware.

By the way, this circle can be used not only for ceramics, but also for cutting thick glass.

By tileOf course, you can use segmented (dry) and turbo discs, but the quality of the cut will be very low, since chips will inevitably form along its edges.

For cutting plastic

Plastic is well cut by the usual abrasive tool for metal. But there is a special saw blade (trident), designed for cutting wood, plywood and plastic. It can be used not only for cutting, but also for longitudinal cutting of material, especially thick.

When installing this tool, it is important to correctly determine the direction of rotation of the Bulgarian spindle.

The use of circular saws with a lot of teeth on plastic and wood is not recommended, because of the high probability of the recoil of the tool, which can lead to injury.

/rating_on.png)

/rating_off.png)