Why Bulgarian, and how it works

Today, in everyday life, almost every home master has a Bulgarian. However, many do not know why it is so called, and what functions this tool can perform, besides the usual cutting. From this article you will learn the origin of the unusual name of the Bulgarian, its device, and what else it can be used for.

How correctly called Bulgarian

All the usual name - Bulgarian - so common that few people remember why it is so called. This tool is properly called an angle grinder (angle grinder). Originally it was intended for processing the internal angles at the joints of two planes. The first copies of such cars came to the Soviet Union from friendly then Bulgaria, where they were made.According to the habit of the people, a long and inconvenient name was tried to be shortened. As a result, a new word, Bulgarian, became firmly in use. But on the packaging indicates the correct name - angle grinder.

Sometimes manufacturers use the option of LUS (angular grinding machine) or LNA.

Gradually, they began to call all the power tools that look like a prototype. Although there is a difference between them. For example, the grinder is often called cutting machine.

External similarity, of course, is present, but the cutting machine is equipped with a platform so that the incision is directed perpendicular to the treated surface, which is how it differs from the grinder.

What can this tool

The classical Bulgarian is a manual power tool with an abrasive circle. The main purpose of the grinder - treatment of joints of flat metal surfaces. However, it can also be used for other operations. The main circle is perfect for cutting sheet metal, butt-cutting pipes and fittings. By simply replacing the working wheel with an emery paper disc, the grinder turns into polishing. Use of the grinder in this quality is possible by treating pipes for railings, flat or curved surfaces to a mirror finish. Except works on metal, the Bulgarian is made cutting ceramic tiles. To do this, as a working disk you need to use a circle on concrete. The list of operations that can be done with the help of the grinder is very wide.

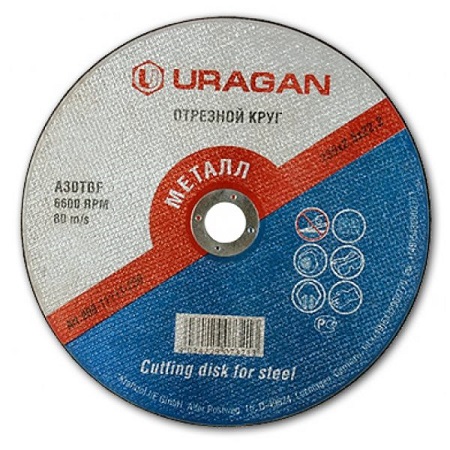

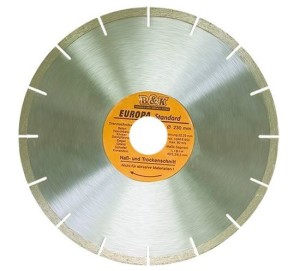

Each type of materials requires special discs for its processing:

- grinding wheel for metal with a thickness of 5-6 mm;

- petal grinding disc;

- cutting wheel for metal 2 mm thick;

- cutting wheel for concrete and ceramics with a diamond edge;

- circle on the cutting tree;

- chain circle on the tree.

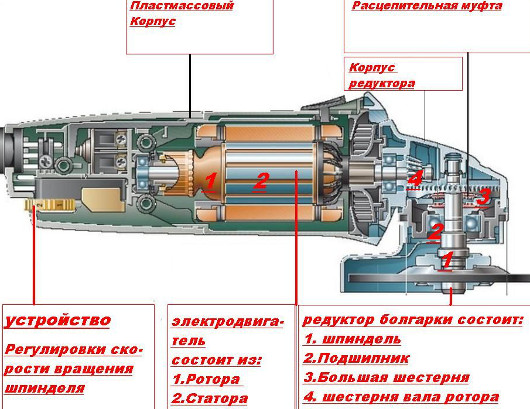

Device and principle of work of LBM

The device of the angle grinder is quite complicated. What LBM consists of can be understood by looking at the figure below.

The design of the machine can be divided into two parts:

- electric;

- mechanical.

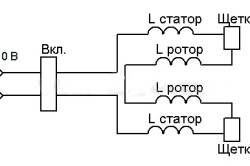

The simplified electrical scheme of the LBM looks like this:

The heart of angle grinders is a collector ac motor. The supply voltage through the stator winding through carbon brushes is supplied to the rotor collector (rotating part) of the electric motor.On the rotor there are winding sections, the conclusions of which are located on the rotor armature plate.

Cheap and low-power grinders rotate at a constant speed. More powerful models are equipped with a knob on the handle, allowing you to change the engine speed.

On both sides of the rotor shaft wearing bearings mounted in the housing. This ensures a stable direction of the shaft during operation. The rotation of the electric motor is transmitted to the gearbox, changing the direction of rotation and transmitting torque to the cutting wheel.

The gearbox consists of two helical gears. Small is worn on the motor shaft, and large on the axis of the gearbox. The outgoing part of the axis of the gearbox - the spindle - fastens the working tool (circle). Professional models are equipped with a tripping clutch - it stops rotating the working part of the tool if, for any reason, the circle is stuck in the material being processed. Without such a clutch, the disk of a circle may break down and shatter in different directions. Part of the surface of the circle is covered protective casingprotecting face and hands from flying out from under the cutting edge of sawdust and dust.

The working circle fastens on a spindle fast locking nut using a special key. The immobility of the spindle when tightening the nut is provided by a button on the side of the gearbox housing opposite to the circle. On the plastic case grinders are longitudinal slit holes. During operation, they cannot be closed, the motor is cooled through them.

/rating_off.png)