Homemade milling machine from the grinder

If it is necessary to perform milling work and the lack of funds for the purchase of factory tools, it is possible at home to make a mill from a grinder. Although it will be inferior to industrial counterparts, it can be used to make grooves and spikes in wood blanks, drill holes, cut edges, cut out spaces for installing door locks and hinges. Also milling can be performed with some other materials, the list of which is determined power angle grindertaken as a basis. For a home workshop, a homemade tool is a good option, requiring minimal financial outlay.

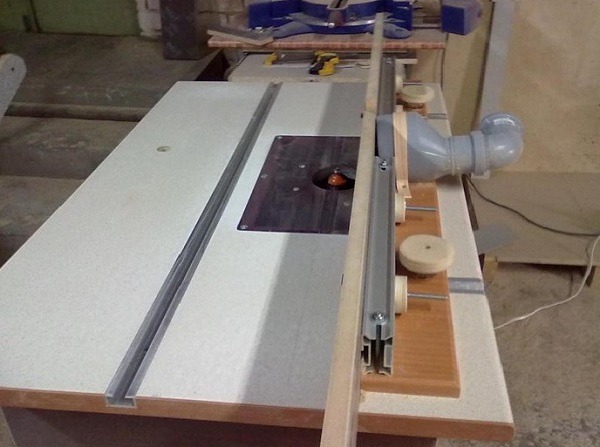

Stationary frame table for fixing grinders

Content

Necessary materials and tools for work performance

Milling cutter is a device designed for processing various materials (wood, metal, plastic, PCB and others): drilling, creating grooves, cutting edges and carrying out other technological operations. It can be made in the form of a hand-held power tool or a stationary machine. For use at home, you can make a grinder from the grinder. At the same time there is an opportunity to realize both stationary and manual versions.

To make a router, in general, you will need the following materials and tools:

- working angle grinder, which will serve as a drive mechanism;

- welding machine (needed when using metal);

- fasteners - punched tape, bolts with nuts, screws or screws;

- screwdriver, equipped with different bits;

- drill with a set of drills;

- roulette and marker (or pencil);

- level;

- gon;

- plywood (chipboard) or metal sheet (about 3 mm thick);

- set of wrenches;

- screwdrivers;

- jigsaw or saws for wood and metal;

- iron corners or wooden bars (5 to 5 cm);

- core;

- hex keys;

- emery paper files.

For work fit sheets of plywood or particleboard with a thickness of 10 mm.

The capabilities of the fixed installation will be determined by the following parameters:

- power of the UShM electric motor;

- the number of revolutions (rotational speed) of the motor;

- dimensions of the desktop, determining the size of the workpiece.

To work with small wooden parts from fragile wood species, a grinder with a 0.5 kW electric motor will suffice. If you have to process metal blanks, you will need a device with a motor of 1.1 kW.

Algorithm for the manufacture of grinders from the grinder

Algorithms for the manufacture of stationary installation for milling and its manual counterpart are different. The last option is easier to implement: less labor is required, as well as materials.

Stationary machines

Milling machine consists of the following structural elements:

- strong, steady bed;

- drive;

- table to perform work with a ruler (rail).

Accordingly, when creating a working model of the installation, you will need to make these parts, and then connect them together. The Bulgarian will be used as an electric drive. It will need to be securely fastened to the table top.

The stationary machine can be made in two versions: with the angle grinder fixed on the table or with the mobile installation of the grinder. The first is quite simple to implement with your own hands. It should be borne in mind that the working tool can be fixed so as to perform processing in the horizontal or vertical planes. The installation order of the installation depends on it.

Machine with workpiece processing in horizontal plane (with the vertical position of the cutter) are collected in the following sequence:

- make a frame from metal corners (they are joined by welding) or wooden bars (fastened with screws, screws);

- sheathe frame chipboard or plywood, fastening the sheets with bolts;

- in the tabletop cut a hole for the shaft of the grinder (of larger diameter than the cross section of it);

- using punched tape or collars, with the help of bolts, a grinder is fixed to the table cover from the bottom, approximately as shown in the photo below;

- on the surface of the table top made of wooden slats (pieces of chipboard or plywood), slats are installed that act as guides along which the workpiece will move;

- wood and metal parts of the structure are painted (pre-cleaned with sandpaper);

- for convenience, fix the toggle switch on the grinder.

The caps of the bolts located on top of the table top should be flush with its surface. Therefore, under them need to drill the notches of the appropriate size. Guides are removable structural elements. Under each billet they need to be rearranged. Often they are fixed with screws.

It is necessary to provide such access to the grinder so that it is convenient to carry out the change of nozzles.

The toggle switch can power the power tool by simply locking its button in the on position. A more complicated option would be the reworking of the LBM electrical circuit.

Option with horizontal cutter implemented in a similar way, only the grinder is fixed on the side of the structure, getting the likeness of a circular saw. The appearance of the created machine is shown in the photos below.

To use the machine, you need install cutters. Their versions are available, resembling ordinary cutting discs, which are fixed on the shaft with a clamping nut.An adapter is required to use keyed nozzles. At the same time, on one side it has a seat with a thread (for tightening the grinder instead of a nut on the shaft), and on the other, for fixing the cutter.

Manual frezer

With a movable fixation option for an angle grinder, it is easier to remove it if necessary, in order to be used for its intended purpose. It is much easier to make a manual mill, than to create a mechanism that ensures its movement back and forth, as well as left and right. Working with such a tool will require secure fixing of the workpieceso that it does not vibrate or move, for example, in a vice or with the help of clamps. This will largely determine the quality of work performed, as well as the convenience (speed) of their implementation.

There are a lot of options for manufacturing hand-held devices from angle grinders for milling. At the same time in the work used different materials. The way to create a hand mill for wood from an angle grinder is shown in the video below.

Manual devices are more reminiscent of the nozzle under the grinder, allowing you to use it as a router.The simplest models do not provide for the vertical movement of the cutting nozzle. They are designed to perform simple operations.

If we compare the manual and stationary versions of home-made milling machines, then it should be noted that the quality of processing of the latter is higher. But it is easier to make the first ones, and the grinder can be easily removed if necessary. Handling of the instrument is required carefully, observing safety precautions. Great when the angle grinder has speed controller. This allows you to set the desired speed of rotation of the cutter while working with different materials.

/rating_off.png)