The better to lubricate the gearbox angle grinder

Any power tool contains in its design rotating parts exposed to increased wear as a result of friction. It is possible to prevent their premature destruction and to prolong the service life of the tool, if it is possible to timely prevent the rubbing parts. In the Bulgarian main subject to wear gears gear. To reduce the harmful effects of friction by applying lubricants to the surface of parts. Consider what kind of lubricant for the gearbox grinder is better to buy.

Content

When grease change is required

With intensive daily use of grinders, the replacement of lubricant in the gearbox should be carried out at least once a year. Often users do not adhere to a specific time frame for preventive maintenance of a tool.and maintenance work carried out after the manifestation of extraneous sounds during operation. This is absolutely not the right method of care for the gearbox.

Gnash during rotation, rattling suggests that the gears formed the development, and they will soon have to be replaced.

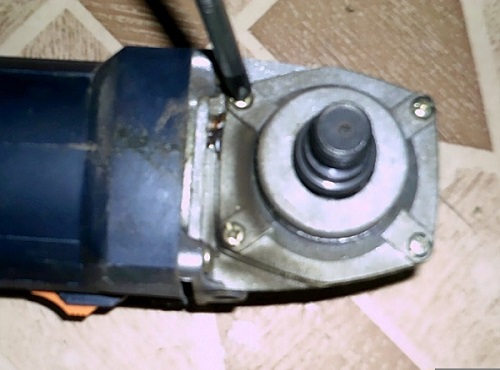

Routine inspection of the gearbox begins with the separation of its casing from the rest of the grinder. It is enough to unscrew the four mounting screws.

The next photo shows that the lubricant is present in the body, but it is assembled on one side of the body, and it is not enough.

This is because the angle grinder (angle grinder) works at high speed. Under the influence of centrifugal force, oil particles tend to move away from the axis of rotation. With prolonged operation, the surface of the gears become completely dry, and without lubrication the metal is erased. In this case, it is enough to lubricate the teeth of the gear with the existing composition, then close the gearbox and work until the next prevention.

Often in the gear can be seen grains of oil mixed with dust. During operation, the Bulgarian is heated, and these grains are sintered, solid particles interfere with the operation of the mechanism.This grease must be replaced.

How to lubricate the gearbox

The choice of gear lubricant has some special features. The rotational speed of the angle grinder is high, the liquid oil will simply fly away from the rotating parts. The thick composition must withstand a fairly high temperature and no sintering

Ready lubricant

Manufacturers of power tools are advised to use special compositions of its own production. Such recommendations are given, in particular, by the firms Makita and Bosch.

You can buy such funds, but their cost is quite high, and the costs are not always justified. Firm "Interskol" more democratic to the type of materials used. What kind of lubricant is better? The lubricant for the gearbox of the grinder must meet certain requirements:

- the viscosity of the composition does not exceed 800 Pa * s;

- the temperature of separation of droplets from the main mass is not less than 120 ° C;

- homogeneous composition without the presence of mechanical inclusions;

- resistance to moisture.

The industry produces many types of lubricants, including special formulations for use in gearboxes. The best results are shown by mixtures containing molybdenum disulfide as an anti-seize additive. If we talk about foreign manufacturers, “Castrol” and “Mobil” have proven themselves well.

"Mobil" for ease of use puts products in tubes having the shape of a syringe.

From domestic brands can be noted MS-1000, Limol. The use of grease, lithol or Ciatim-221 does not give the desired result.

Homemade mix

In the absence of the sale of the desired lubricant or, if the user considers the price of the product to be unreasonably high, you can try to make the lubricant mixture yourself. There are several recipes using different basics. One of them - common Ciatim-221.

Add TAD-17 gear oil to the tank with Ciatim. Stirring continuously, add the oil one drop at a time until the desired consistency is reached. The mixture must adhere well to the parts, not be too thick and do not flow like liquid oil.

Another basis may be grease for CV Joints in combination with MS-20 liquid oil.

How to produce lubrication gear

It is unreasonable to add the missing amount of oil to the gearbox housing: a good composition is mixed with the already used one, and the new lubricant loses its efficiency more quickly. Therefore, when the gearbox and its case are removed, the remnants of the old grease are removed from the cover. First, use a dry cloth, and then wash out traces of gasoline or kerosene. After the parts dry, a new lubricant is applied to them, and the gearbox housing is filled with lubricant 2/3 of its volume.

After the grinder is assembled, its shaft is rotated by hand several times to evenly distribute the oil. Rotation should be uniform, without jerks and jamming. Making sure that everything is normal, turn on the device in the network and get to work. With timely prevention tool will last for a long time.

/rating_on.png)

/rating_half.png)

/rating_off.png)