The device and the principle of operation of the iron

The principle of operation and the internal structure of the iron, at first glance, do not raise special issues: electric current leads to heating of the nichrome spiral, which, in turn, transfers heat to a massive metal plate - the sole. But how does the heating temperature, steam flow or water spray adjust? Modern models of irons can be equipped with a variety of systems to prevent the formation of scale, electronic components and regulators, the presence of which significantly complicates the design.

Independently understanding the device of a modern iron is not easy, however, possession of such information can help in the elimination of minor faults. Given the high complexity of the design of the iron, for a serious repair (replacement of the helix or electronic components, cleaning the water supply pumps,restoration of electrical wire) is recommended to contact specialized workshops, since the device’s performance after unauthorized intervention is not guaranteed.

Content

What parts does the iron consist of?

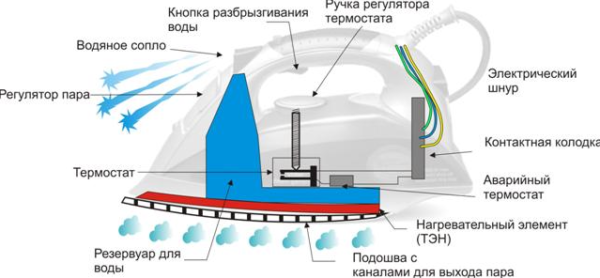

Such a household appliance, as an iron, is rather complicated from a technical point of view, a device. The iron circuit includes several dozen elements, chief among which are the heating element, thermostat, overheat protection system, as well as various regulators, indicators and other electronic components, without which it is impossible to imagine the normal operation of a modern iron.

How does a modern iron, many models of which can be seen on store shelves? First of all, the following components should be distinguished in its structure:

- electrical wire;

- steam supply system;

- water chamber and steam generators;

- sole;

- thermostat.

Considering each of the elements separately, special attention should be paid to the internal structure and working principle of the parts, since such information makes it possible to determine the cause of breakdowns and ways to eliminate them.

Electrical wire

Although at first glance the wire for an iron is no different from a similar element of other household appliances, some features are traced in its appearance and internal structure: first of all, the wire has a fabric braid that interferes with the rubbing of the polymer shell during ironing.

It is difficult to imagine any other device that is subjected to the same heavy loads as an iron, because when using it, you have to twist the cable several times in different directions, stretch it, bend it at unimaginable angles, and even by negligence turn into a knot.

An ordinary cord could not withstand such manipulations for long, while the wire from the iron copes with its duties for several years or even decades.

The secret lies precisely in the fabric sheath: it reduces the coefficient of friction between different parts of the cable several times and also increases its rigidity. As an additional element, giving maximum reliability to the system, a plastic limiter is used, which is located near the base of the iron and is designed to prevent possible wire bending.

The inner part of the wire for an iron is represented by three conductors, one of which is used as a ground. Such a safety measure makes it possible to reduce the risk of electric shock in the event of a short circuit and to extend the life of the device.

Steam supply system

Most modern models of irons are equipped with two buttons that are located in the front of the device: one of them is responsible for steam supply, and the other allows, if necessary, to moisten the fabric by spraying water through a special hole located on the tip of the iron. The transformation of water into steam occurs in a separate chamber, which is equipped with powerful heating elements.After pressing the button, the liquid under pressure penetrates into the chamber, where it instantly heats up, and is distributed through the perforations on the sole of the iron.

The use of untreated water from the tap often leads to excessive formation of carbonate deposits on the surface of the heaters, which naturally leads to a decrease in the efficiency of heating, and the removal of heating elements from the system. The appearance of traces of rust, dirt or fragments of scale on the fabric during ironing is an alarming signal, which indicates that the time has come to pay extra attention to cleaning the iron.

Sole and heater system

From the sole, as the main component of the iron, depends not only the quality of ironing, but also the overall level of comfort when using the device. Manufacturers of modern irons equip their soles with Teflon, ceramic or even sapphire coating - this technical solution allows to reduce the coefficient of friction between the sole and the fabric, thus facilitating the process of ironing. Inexpensive models of irons are equipped with an aluminum sole, the main disadvantage of which is considered to be excessive metal compliance, which often leads to noticeable scratches.

Inside the sole there is a heating element - a nichrome spiral, supplemented with ceramic rings that evenly distribute heat and help preserve it for a long time. The heating temperature is set by a separate thermostat, the main function of which is to timely turn off the power supply in accordance with a given mode.

Thermostat and heating shutdown system

The use of an iron on various types of fabric involves careful selection of a suitable temperature.

In most cases, the requirements for ironing are indicated by the manufacturers of clothing on a separate label that is sewn into the folds of the product.

The adjustment of the heating is done by setting the rotary wheel of the iron to the required position corresponding to the permissible parameters of ironing. When the temperature reaches the maximum value, the contact opens, causing the supply of voltage to stop.

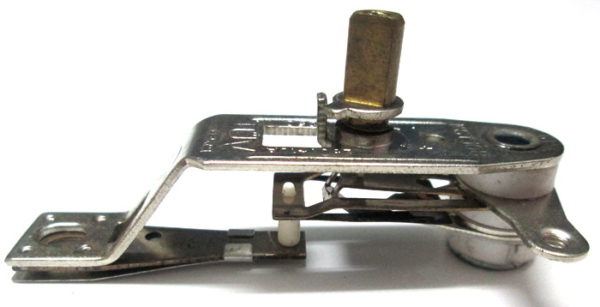

How does the regulator shut off? Electric circuits of irons suggest the presence of a special element - a bimetallic plate, which consists of two parts made of metals with different coefficients of thermal expansion.When heated, the metal is deformed, and differences in the properties of the constituent parts of the plate lead to a slight deformation, as a result of which the plate is retracted upwards and stops contacting with the electrical circuit. A similar principle of operation is used not only in irons, but also in kettles, relays of switching off boilers and other heating elements.

Typical irregularities of the iron and how to solve them

Iron breakdowns are mainly due to improper operation, sudden voltage drops or insufficient tightness of the water compartment, moisture from which leaks onto the electronic components of the device. Determining the cause of the malfunction, given the considerable complexity of the design of modern irons, is not easy, however, there are a number of typical signs that reduce the number of searches:

- When the iron is connected to the mains, the indicator light does not light up and the sole does not heat up. First of all, you should check the serviceability of the outlet, since it is often the reason that causes the breakdown. If the network is OK, then the next source of the problem may be a violation of the integrity of the network cable.In addition, a break is often detected directly in the area of the soleplate, where a small fuse is located that burns out if it is excessively heated.

- The indicator light is on, but the heating does not work. In this case, the cause of the fault should be sought in the heating element or the fuse described above, since it is from these elements that the power supply to the sole depends.

- During the steam supply from the holes in the sole, rusty water with fragments of scale begins to seep. A similar problem is observed when a certain amount of moisture gets directly onto the electronic components of the iron: during the contact of a switched on device with moisture, an electrochemical reaction occurs, which leads to a slow destruction of the metal. The process is enhanced with the use of water, which contains a large amount of salts, organic and inorganic impurities.

How to extend the life of the iron?

In order for the iron to serve you as long as possible and not to cause problems with its work, you should follow a few simple tips:

- Avoid careless handling of the iron: the electronic components of the device do not tolerate sudden blows, falls or temperature drops.If your iron is equipped with a ceramic sole, then its vulnerability, due to the fragility of the material, increases significantly.

- For filling the iron, it is recommended to use distilled water or a special flavored liquid, which can be found in household chemicals. It is completely unacceptable to use even purified water or to fill the iron directly from the tap, since such treatment leads to a rapid accumulation of carbonate and ferrous deposits.

- If you store the iron on a balcony or in another place where the temperature is significantly different from room temperature, then after transferring the iron to a warm room, it is recommended to allow it to “acclimatize” a little, due to which all condensate that accumulates on the contacts will have time to evaporate.

- Any contamination appearing on a metal sole should be immediately removed by special means. Also, ironing of plastic elements, zippers, decorative patterns, glitters and prints is not allowed, since they melt fairly easily and can greatly pollute the sole.

The main principle of operation of irons is the uniform heating of the metal sole and the distribution of water vapor in the thickness of the fabric.Observing simple precautions, you can not only significantly extend the life of the equipment, but also to avoid most common breakdowns.

/rating_off.png)