Self repair iron Tefal

Repair of the Tefal iron is a task that requires at least some experience with the tool. You should know that some models of the brand can not be repaired at home without special equipment and skills. Consider how you can repair the iron of this brand with your own hands.

Content

Models that you should not repair yourself

A device that you can not even try to repair with your own hands is wireless iron Tefal. On the market are various options for such devices:

- with contact pads;

- with heat accumulating sole;

- with a power cable.

The first two categories clearly require diagnosis, disassembly and repair using special equipment: it is unlikely that it will be possible to repair a similar iron at home. The third category has a clearly defined weak zone. The scheme of work looks like this:

- An iron with a cable connected to a special mechanism is connected to a 220V network.

- Upon reaching the set temperature controller, the cable is fired off with a spring block.

- Until the temperature drops, the cable cannot be inserted into place: it is not fixed, and in some models it is not even inserted.

The problem of irons with shooting a cable is one - they have two thermal control mechanisms: the main and fixation of the cord. Over time, the owners of such a model will have to go to the following scheme of action: having stroked a piece of clothing, wait for the temperature to drop, insert the cord, move the regulator to a greater value and wait again. The reason for this behavior of the iron - in the oxidation of the bimetallic plate control device shooting. It is enough to clean, replace, in some cases - just fix it.

Body disassembly

How to disassemble the iron from Tefal correctly? They provide multilevel mounting scheme. The following features are available:

- The top cover is not removable with the main body.

- To get to the electronic components, you need to unscrew the screw in the bow. It can be seen in the area of the water dispenser through translucent plastic.

- Access to the steam supply devices is carried out after removing the top cover. To do this, you need to dismantle the buttons, which close access to the mounting screw. Unscrewing them, you can remove the top cover and get full access to all components of the device.

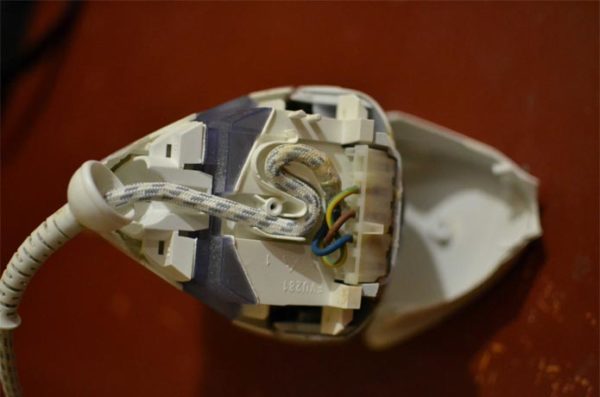

The initial disassembly of the Tefal case is no different from the scheme used in other brands:

- It is necessary to remove the clamping screw or the screws that are under the cover in the back of the case. Screw them in deep to unlock and remove the cover.

- Under the lid may be several fasteners located under the water tank or under the plastic head of the thermostat.

- Raise the plastic case to be neat. In addition to screws and screws, it can be fixed snaps. You can find them with a thin strip of steel (blade of a knife or a screwdriver) by holding the body.

- To gain access to the electrical part, it may be necessary to remove the protective cover.It is also fastened with several screws, which are easy to find.

Tefal irons can have a complex body shape, so you should carefully and thoroughly inspect it for the presence of open or hidden fixings and fastener points.

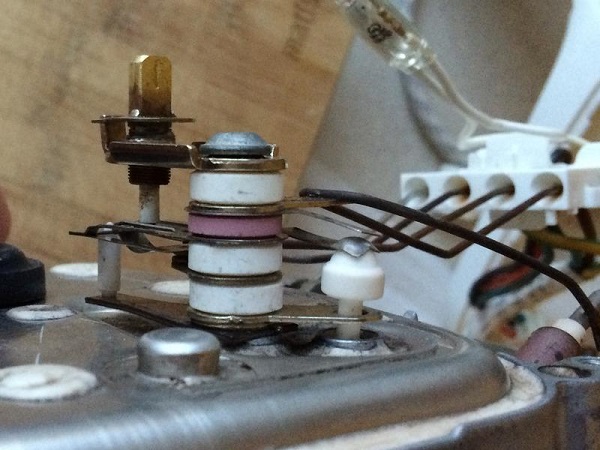

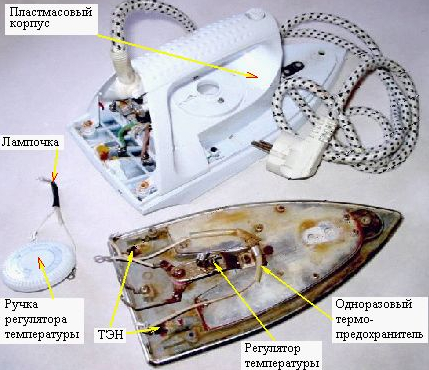

After removing the upper case and the inner protection covers, the disassembled iron looks like this:

It does not matter which model of iron is disassembled for repair and diagnostics. Devices with a steel sole or Ultragliss brand have the same nodes. Problems can arise from the failure of a one-time thermal fuse, contact oxidation, clogging of steam, contamination and the effects of corrosion due to moisture ingress to live areas.

Typical faults and how to eliminate them

Among the irons Tefal common following damage.

Stalking or failure of the steam button

In Tefal irons, the steam supply is not activated by a button command. This plastic part presses against the hollow tube, which transmits force to the corresponding contact. The detail often breaks with time. It is useless to glue - the tube has thin walls and will not have sufficient strength.For repair you will need a shrinkable hose, it can be purchased at a radio electronics store. The hose is put on a plastic tube and heated, for example, with a cigarette lighter. After repair, the part is installed in its proper place.

Power cable failure

The most common problem of irons is in power cord damage. It is necessary to check the condition of the fuses (one of them may be in the plug), the absence of carbon on the contacts, the absence of scuffs, creases and other mechanical damages. Particularly carefully investigated the area of entry of the cable into the plug and the body of the iron. If damage is detected, the cable must be replaced. A close-up contact pad located in the rear part, under the housing cover, is also carefully examined.

Oxidation

The entire construction of the iron is carefully inspected. Areas where lime deposits or oxidations are present are cleaned. For this purpose, small skin, brush, light acid detergents, ethyl alcohol can be used. The cleaning procedure is obligatory - in most models, water and steam directly fall on the current-carrying circuit elements.

Clogged steam outlet holes

You can clean the sole in several ways.One of them is to use cotton buds moistened in vinegar. They are pushed as deeply as possible into the nozzles and turned. The availability of other methods depends on the material of the sole:

- Metallic - cleaned with salt. It is enough to iron the cotton fabric covered with small salt at maximum heating.

- Ceramics and metal can be cleaned with a weak solution of citric acid. To do this, take a large frying pan into which the solution is poured (about a centimeter) and put 3 coins. The iron is installed with a sole on these coins, but so that its nozzles are not closed. After that, the solution is brought to a boil and cooled in a natural way. The procedure is repeated 3-4 times.

Before cleaning, clogged nozzles should be pierced with a toothpick or needle. Teflon-coated irons are best given to a specialized workshop. Depending on the characteristics of the surface and the period of use, household methods can lead to detachment or other disturbances in the smoothness of the sole.

It is not recommended to clean the irons with vinegar. Exposure to high-temperature acid causes oxidation of the working circuits of electricians, leads to plastic fragility, and can lead to irreparable damage to pumps and regulators.

If it is decided to use citric acid, contact zones should be protected. Wrap the place of attachment of wires TENA iron tape or close with shrink, for example.

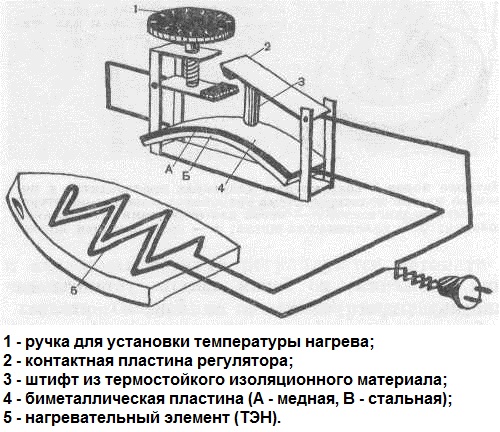

The thermostat is working badly.

Cleaning the iron thermostat is quite simple. The site is dismantled and remove soot from the contacts. A suede strip is suitable, which is moistened with alcohol or citric acid, is pulled between the contacts (zone 2 in the diagram) and driven until the amount of dirt decreases. It is not recommended to use skins and abrasives - the surface becomes rough, current surges are stronger, as a result of which the burnout occurs even faster.

In the iron thermostat can fail bimetallic platewhose task is to interrupt the electrical circuit. The item is not repaired, only replaced. Another problem - breaking stock. It is made of ceramic, the part can be made of improvised material, for example, a resistor, if desired. But in most cases it is easier to change the iron thermostat entirely.

These repair actions can be done by hand with even a little experience with electrical engineering.More complex operations, such as troubleshooting problems with the iron position sensor or electronic components, are better to be entrusted to specialists.

/rating_off.png)