How to fix the iron with their own hands

To fix the iron with your own hands, you need to know how this device is made. Considering iron deviceIt can be said that it is structurally similar to such devices as a kettle or a heater. The differences are only in the purpose of the devices and the presence of additional nodes.

In the iron, regardless of the country and manufacturer, there are four main nodes:

- heater;

- plug with cord;

- thermal fuse;

- Temperature regulator.

In order for the iron to start working, it is necessary to apply voltage to the tubular heating element located in the bottom of the device. In modern models, such as the "Roventa", used powerful heating elements from 1000 to 2300 watts. If you do not interrupt the process of heating, then the sole of the device will become so hot that it will be suitable except for frying eggs, and not for ironing.

In order to prevent excessive heating, a regulating device is built into the apparatus circuit.The thermostat of the iron depends on the thermal mode, which is selected based on the type of fabric: some materials can be ironed at a temperature of 100 ° C, others need indicators of 200 ° C. In most models, which include Brown irons, the adjusting wheel is located in the upper part of the body under the handle.

An important node for safety is the fuse. When the device reaches extreme temperatures resulting from a malfunction, the thermal fuse will open the contacts and the iron will turn off.

Content

Supply wire faults

Before repairing the iron, you need to check the condition of the power cord. Most often it cracks in places of frequent deformation - at the entrance to the body or near the plug. The malfunction may occur gradually when the indicator light flashes during ironing. Such a wink means that there is no normal contact and terminal oxidation is possible.

Another malfunction manifests itself more violently.At long friction of wires against each other the insulating layer can be broken and short circuit can occur. Outwardly, this is manifested by strong cotton, disconnection of other devices and a specific odor characteristic of burnt wiring.

Women who are particularly susceptible, such situations are hurt to the depths of the soul. They perceive the breakdown as a natural disaster and react by calling her husband, in the Ministry of Emergency Situations and house management. The most correct option is the first one, because any man whose hands grow from where they should come from can force the iron back on. Otherwise, you should still turn to the strong half so that he will hand over the thing for repair.

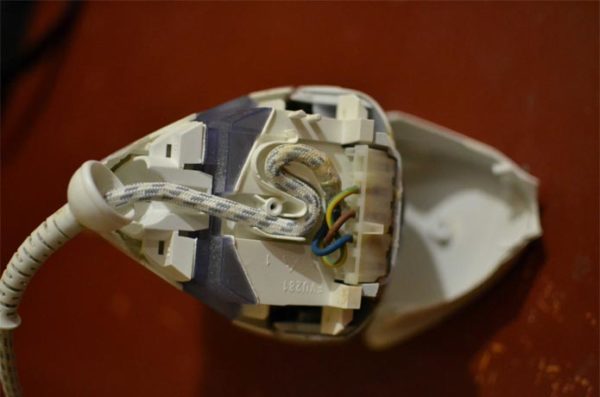

The Internet is filled with videos on the repair of irons. Many plots are devoted to the flaws of the power cord. If the cord is defective near the plug, you will not need to disassemble the device. In the case when the suspicion falls on the part that is hidden by the body, disassembly is indispensable. To make, for example, the repair of the iron "Philips" with your own hands, you should remove the back cover. Behind it, the power cord diverges into three wires. If the insulation is damaged, it must be repaired.When oxidizing the terminals, you need to disconnect the wires and clean the problem areas.

Electric Heater Check

The heating element in modern designs is a reliable knot and rarely breaks. When this trouble occurs, it is better not to buy a new heater. Easier to buy a new iron. But first you need to make sure that the problem is in the heating element.

In all models, the heater contacts are soldered to the contacts of the device and are connected to an indicator lamp. If the lamp is on, and the iron does not heat up, then the fault is related to the heating element.

The most common cause of failure of the heating element is a spiral break. Another reason may be insufficient contact of the heating rods with the leads of the device at the connection points.

In some models, the thermal fuse is connected to one circuit of the heater, and the regulator is connected to another. If the fuse is faulty, you can make a false "diagnosis", suspecting a malfunction of the heater. To accurately determine the cause of the failure of the device, it should be completely disassembled.

Problems with thermostat

Temperature control is carried out by a round wheel. It is located in the iron "Azur" and in other models on the body under the handle.When the wheel is turned to the right, the heating temperature increases, to the left it decreases until the heating element is completely turned off.

The wheel acts on the thermostat by means of a special sleeve or steel angle and is attached to the body with the help of latches. In the Scarlet iron and in other models, it is enough to pick up the adjustment disk with a screwdriver so that it will come off.

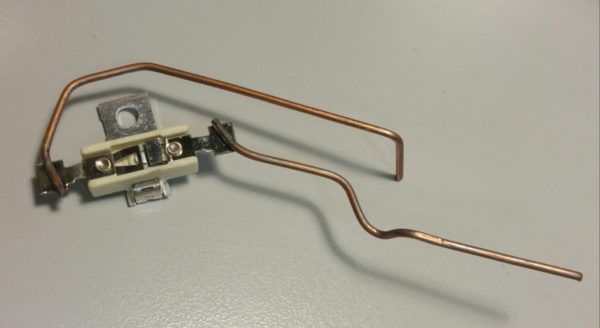

The principle of operation of the thermostat is based on the various properties of metals. In the manufacture of this site soldered two plates made of metals with different linear expansion coefficients. Thanks to these indicators, the plates behave differently. Outwardly, it looks like this: under the influence of temperature, the common plate is bent, causing an open circuit, and the iron is turned on.

To make sure that the temperature regulator is faulty, you will have to disassemble the iron completely.

The handle of the device and the plastic parts of the case are attached to the metal parts with latches or self-tapping screws. Even one manufacturer of models has many, and they all have design features. But there are common moments in all species.

To disassemble the iron, it is necessary to examine its sharp part, where there is one point of attachment.For example, a Philips iron hides a screw under the steam adjustment knob. To unscrew the screw, turn the knob all the way to the left and pull up. After removing the adjustment knot, you can loosen the screw. In the “Brown” model, the screw hides under the nozzle cap. You can remove the nozzle by slightly pulling it towards you. After its removal opens free access to the screw. Other screws or latches are located under the back cover of the device.

After the plastic part of the case has been removed, the iron thermostat should be considered. In cold mode, the contacts must be closed. If there is a special device, it is better to call the node. If the device is not, you can clean the contacts with fine sandpaper, then turn on the iron in the network.

Blame and other faults are at fault.

To fix the iron, you can refer to the statistics, which says that 50-60% of faults occur due to the fact that the thermal breaker fails. This node is a one-time action and reusable. Fuses of the first group, like kamikaze, work only once. The node is designed so that when the heating element reaches a temperature of 240 ° C, the circuit is broken.Further operation of the device without additional intervention becomes impossible.

More modern technologies involve the use of bimetallic parts. Such a thermal fuse is able to turn off the iron in extreme situations, and then turn it on again. If the iron does not work for this reason, the easiest way is to throw the knot out and close the circuit. This can be done in different ways:

- by soldering;

- by crimping the metal rod;

- switching power wires.

In each case, you need to achieve reliable contact.

Another common disease is a problem with the steaming system. Sometimes in the “Bosch” iron, the button, which includes the process, is strongly pressed, and steam is not supplied. Repair of the Bosch iron should begin with unscrewing the screw at the back and removing the back cover. Then you should gently pull the two buttons that regulate the flow of steam up. They are not fastened with screws and are held on bushings by frictional force. Next you need to unscrew the screw, after which the plastic handle should be easily removed. Under the lid are two pumps: one supplies water to the sprinkler, the other delivers water to the sole to create steam. The steam pump must be removed.At the bottom there is a ball that sticks to the bottom of the chamber because of scale. To eliminate the malfunction, push the ball into the chamber and assemble the iron in reverse order.

Whatever iron you have to repair, you need to remember about safety and follow certain rules: turn on the device in the network only when necessary; do not attempt to fix the problem with wet hands; during repair, the iron must be installed on a stable, impermeable and heat-resistant coating.

/rating_off.png)