Connecting the engine from an old washing machine

Every user knows that the electric motor is the artificial heart of any household appliances, and that it rotates washing machine drum. Each home master is interested in the question: is it possible to connect the motor from the washing machine to another device on its own?

Content

Application options

It is not so difficult to make it, even for a person who is absolutely not familiar with the basics of electrical engineering. Let's say you have car broke down Indesit, but the engine with a power of 430 W, which reaches a speed of up to 11,500 rpm, is completely intact, its lifespan is not exhausted. This means that it can be used for household needs.

There are many different ideas on how to use and reconnect an engine from a failed one. washing machine.

- The simplest option is to make grinder, because the house constantly need to sharpen knives, scissors. To do this, it is necessary to firmly fasten the electric motor on a solid base, fix the grinding stone or the grinding wheel on the shaft and connect it to the network.

- Those involved in construction can do concrete mixer. For these purposes, the tank from the washing machine is useful after a little refinement. Some do homemade vibrator for concrete shrinkage is a good way to use the motor.

- Can do vibrotable, if you are engaged in the production of cinder blocks or paving slabs in your backyard.

- Kruporushka and mill for grinding grass - a very original use of the engine from old washing machineindispensable for those who live in rural areas and breed poultry.

There are a lot of use cases, all of them are based on the capabilities of the motor from the washing machine to rotate various nozzles or activate auxiliary mechanisms. You can choose the most unusual version of the use of the removed equipment, but for the implementation of the plan, you need to knowhow to connect the engine from the washing machine correctly so that the winding does not burn down.

Washing machine motor

Connection Tips

When using the powerful engine of a washing machine in a new incarnation, you should remember two important aspects of its connection:

- such units do not run through the condenser;

- not needed and start winding.

Before connecting, we advise you to deal with the wires of different colors present on the transfer case:

- two white wires are from the tachogenerator, we will not need them;

- brown and red - go to the winding to the stator and the rotor;

- Gray and green are connected to graphite brushes.

Be prepared for the fact that in different models wires differ in color, but the principle of how to connect them remains the same. To detect pairs, ring the wires one by one: those going to the tachogenerator have a resistance of 60–70 Ohm. Take them aside and tape together with tape so that they do not interfere. Ring the rest of the wires to find them a pair.

We understand the connection scheme

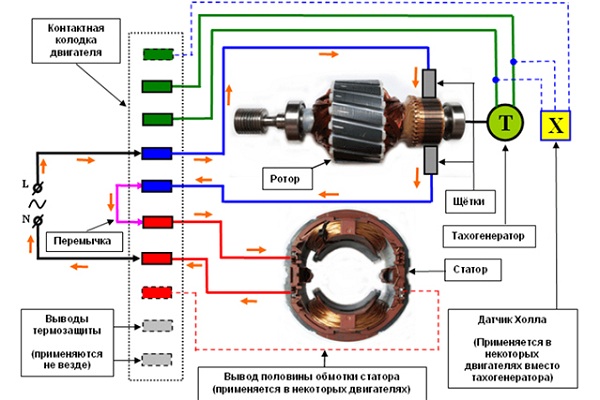

Before further action, you should be familiar with the wiring diagram - it is very detailed and understandable to any amateur home master.

Connect the engine of the washing machine is not so difficult as it seems at first glance. First of all, we need wires from rotor and stator: according to the scheme it is necessary to connect the stator winding with the rotor brush. To do this, make a jumper (it is marked in pink), and isolate it with electrical tape. Two wires remain: from the rotor winding and the wire from the second brush, we connect them to the home network voltage.

Attention! If you connect the motor to 220 V, it immediately begins to rotate. To avoid injuries, you must first firmly fix it on any surface: this way you guarantee the safety of testing.

You can simply change the direction of rotation - jump the jumper to other contacts. To switch on and off, connect the corresponding buttonsYou can do this with the help of the simplest connection diagrams that can be easily found on special sites.

We briefly described how to connect the engine from an old washing machine to use it for the needs of the household, but now we need a little improve new device.

Speed controller

The engine from the washing machine is quite high, so you need to make a regulator so that it works at different speeds and does not overheat. For this fit ordinary light intensity switchbut a little refinement is required.

- Extract from the old typewriter triac with a radiator, the so-called semiconductor device - in electronic control, it performs the function of a controlled switch.

- Now you need to solder it into the relay chip instead of a low-power part. This procedure, if you do not possess such skills, it is better to entrust a professional, familiar electronic engineer or computer programmer.

In some cases, the motor normally copes with the new work without a speed controller.

Regulation of turns of the motor

Types of engines washing units

Asynchronous - removed together with the condenser, which are of different types, depending on the model of the washing machine. It is advisable not to break its connection with a battery whose case is sealed, made of different metal or plastic.

Caution! Such an engine can be removed from the machine only with a fully discharged capacitor - a current shock can be quite significant.

Low voltage collector Motors are distinguished by the fact that permanent magnets are placed on their stator alternately connected to a DC voltage. There is a sticker on the case, where the voltage is indicated, which is not recommended to exceed.

Engines electronic type must be dismantled together with the computer - an electronic control unit, on the case of which there is a sticker indicating the maximum possible voltage connections. Observe the polarity, because these motors do not have reverse.

Possible faults

Now you know how to connect the electric motor to give it a new life, but it may turn out to be a small incident: the engine did not start. It is necessary to understand the reasons and find a way to solve the problem.

Check out motor heating after his work for a minute. In such a short period of time, the heat does not have time to spread to all the details and it is possible to accurately fix the place of intense heating: the stator, the bearing assembly or something else.

The main reasons for rapid heating are:

- wear or clogging of the bearing;

- greatly increased capacitor capacitance (only for asynchronous motor type).

Then we check every 5 minutes of work - three times is enough. If the wine is in bearing - disassemble, grease or replace. During the further operation we constantly monitor the engine heating. Do not allow overheating, repairs can cause great damage to your home budget.

/rating_on.png)

/rating_off.png)