Independently lubricate the bearing in the washing machine

Noise during spinning, when the drum is spinning at high speeds, says that it is time to lubricate the bearings so that they do not have to be urgently replaced. Tightening this procedure is not worth it: the body can wear out. This operation is simple, although it takes a lot of time - it all depends on what brand of home appliances you have. We learn how to lubricate the bearing in the washing machine, and what kind of lubricant you need to apply.

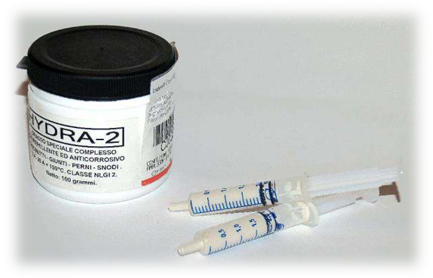

Grease selection

The industry produces a large range lubricants for all occasions, and you need to navigate this abundance. Before you buy high-quality lubricant, it is better to consult with knowledgeable people.

Professionals advise to avoid the use of automotive types of lubricants - they are ineffective in the conditions of operation of washing machines, require frequent replacement.

In specialized service centers you can offer:

- Amplifon - waterproof bearing grease from Italian developers;

- Anderoll - from manufacturers of Indesit machines, sold in jars of 100 g or in syringes, dosed for two uses;

- Kluber Staburags NBU 12 - retains viscosity up to 1400 C, available in containers up to 1 kg;

- Liqui Moly Silicon-Fett - German silicone grease, in tubes of 50-100 g;

- Huskey Lube-O-Seal PTFE Grease is a multi-purpose, fully synthetic, ultra-water resistant, plastic grease from the USA.

The last two types of grease are of the highest quality, so the price is appropriate. Choose what you can afford, and the principle of action is the same for all: quality tightness bearing assembly excellent viscosity.

Washing machine disassembly

After the selection of lubrication proceed to the process of disassembling the machine. It will take almost complete disassembly to get to the tank, and then it must be disassembled into its components.

Before the start of dismantling, take a look at the appearance of the machine, each node, so that later, during assembly, you do not have questions.

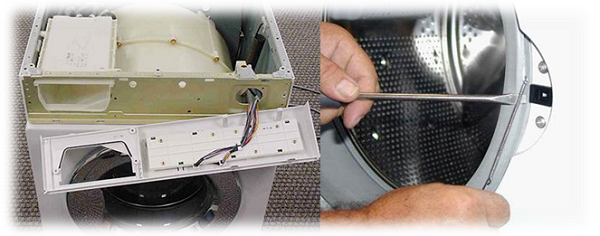

- Turning off the machine, set it so that there is a free approach from all sides. First we shoot top cover and back panel - A detailed description of all stages of disassembly with photos is on the Internet, so we only point out the main points.

- We take out dispenserdisconnect Control Panel: here you need to be especially careful not to tear the wiring.

- Then we do cuffed on the linen loading hatch - pry out the spring with a screwdriver and remove the collar of the cuff.

- Disconnect the edges of the rubber seal from the wall, refill the cuff inside the drum. We unscrew the fasteners of the wall and carefully remove it so as not to tear the wire leading to the lock of the manhole lock.

- Now delete dispenser housing, disconnect all wires, connections, remove the main counterweight to remove the tank without interference.

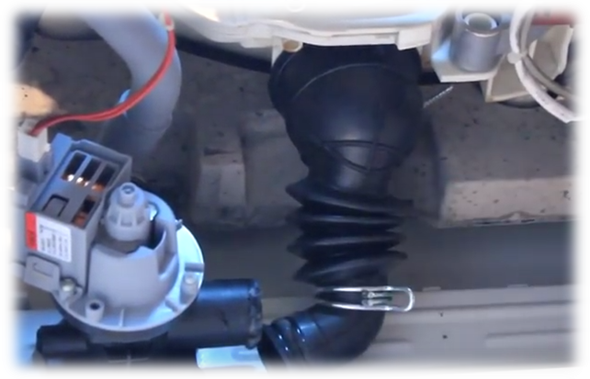

- Dismantle bottom cover - the bottom of the machine to get to the bottom mounting tank. Disconnect drain pipe, for this we unwind the mounting clamp, carefully remove from the tank and disconnect from the drain pump.

- Take off a heating element. Here it is necessary to take a pre-photo so as not to confuse anything TEN at different models of washing machines is behind or in front.All wires are carefully disconnected, while carefully inspecting their attachment to various parts, so as not to miss anything, after dismantling we pull them out of the car.

- Everything counterweights unscrew to ease the tank. Disconnect the water level sensor, shock absorbers, rear mounts, which is on the tank, for this, unscrew the bolts.

- When all mounts are removed, remove belt from the pulley, push the arm into the tank, lift it up, disconnect the springs and pull it out.

Tank disassembly and bearing replacement

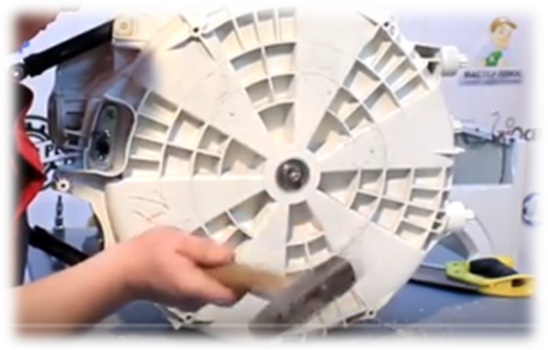

Inspecting the tank: in some washing machines it is solid, in the other - of the two halves. If the tank welded, then we saw it gently along the seam with a grinder, then you can join the halves with the help of bolts and silicone-based sealant.

Having examined the tank, proceed to the removal of bearings:

- The pulley of the drum is fixed with a nut, which can be unscrewed with an axle spanner.

- Loosening the pulley body, remove the drum.

- Carefully knock the shaft, separating the drum and the tank body. From the inside and outside are the desired products.

- To remove use a special puller.

Caution! The pulley mounting bolt is unscrewed quite difficult - lubricate it with WD-40, which will penetrate to the places where the nut stuck to the bolt thread, and after a while try to unscrew.

Dismantling the bearings, inspect them and oil seals on the subject of health and integrity. Only after that proceed to the lubrication: clean the old grease with WD-40, wipe thoroughly with a dry cloth and grease. This is the easiest part of the whole process.

Bearings must be lubricated at least once every five years.

Then repeat all your actions will be in the reverse order. To facilitate the work there is a video:

/rating_off.png)