Why does the sewing machine skip a line

Like any mechanism, a sewing machine is subject to various breakdowns, however, for devices of this type there are typical and most often encountered cases. For example, why does the sewing machine skip stitches while stitching? To answer this question you need to look inside the device and learn the features of its functioning.

Content

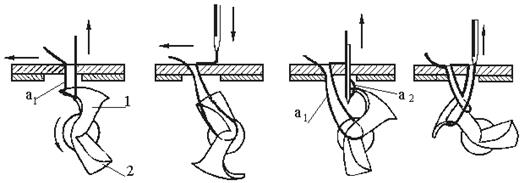

How a stitch is formed

The so-called sewing line appears as a result of the interaction of a needle and a special shuttle device. The bow of the shuttle moves close to the needle and lifts the loop from it.After this, the part winds up the upper thread and creates a shuttle stitch.

If the mechanisms work smoothly, and the setting of the sewing machine is not broken, omissions in the line during sewing are excluded. However, in case of non-observance of the rules of operation or as a result of deterioration of parts in the process, malfunctions may occur. Consider examples of situations that lead to the formation of gaps in stitches, and how to eliminate them.

Shuttle Shuttle

The distance between the needle point and the nose of the shuttle exceeds 0.3 mm allowable. In some cases, the gap may diverge by more than a millimeter. This leads to the fact that the shuttle, passing by the loop, is not able to grab the thread and form a stitch. This occurs as a logical result of the use of low-quality fabrics and threads, defective needles, defective parts. Also, gaps are caused by poorly stretched threads and incorrectly sized needles. To eliminate the problem, carefully inspect the shuttle part of the device and perform the necessary procedures for restoring work.

Injured needle

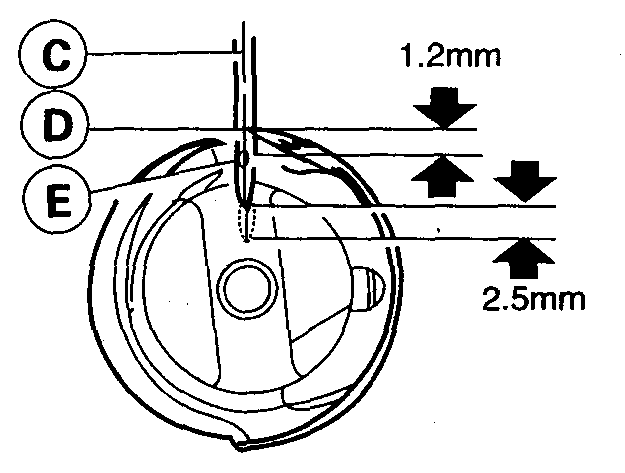

Incorrect sewing machine settings may cause the sewing machine to skip stitches.Over time, especially after frequent use, the needle of the sewing machine can change its position or even bend. This can affect not only the evenness of the line, but also the work as a whole. To eliminate the problem, remove the bobbin case and carefully inspect it.

- Examine the state of the needle: if it is deviated to the side, blunt the tip or has external damage, replace it with a new one.

- When installing a new part, make sure that it is inserted all the way. Also check the tightness of the special screws for fixing. If it is loose, use the included screwdriver and tighten it.

- Get the needle in the correct position. Inspect the bobbin case jack. Slowly turn the handwheel and observe the movement of the needle. Make sure the needle drops below the top of the thread hook.

- With help needle bar achieve the desired height for the needle. Gently lower it until you see the correct position of the part.

- See how the thread behaves, passing through the mechanism. Put the quality material in the machine and set the flywheel in motion.Achieve free passage of the thread, without hitches and excessive tension.

Adjusting such a precise mechanism requires special attention and scrupulousness. If you do not have enough patience, or you lacked the right tools, consult a competent specialist.

Incorrect thread

Seagull sewing machines, as well as models of other firms, may not work properly due to inconsistencies in the thickness of the thread to the needle. A small or too thin needle simply cannot manipulate bulky material, skipping stitches or making them uneven. Loop-lapping will be easier to form on the other hand, breaking the harmony of work. To eliminate choose a suitable numbering thread. Before work, do not forget to consult the operating manual of the device.

High deflection angle

The loop required for a stitch is formed on the back side of the shuttle. A higher angle increases the chance of skipping a stitch, as does a loop that is too small. What to do in a similar situation? Try to give the needle bar the right angle, take care not to damage the device. In addition, the part can be upgraded by adding on it new search. Choose a suitable angle for your device and carry out the necessary procedure.

Formation of loop-inlet from the side opposite to the needle

The phenomenon is common in mechanisms using polished threads. Their elasticity is several times higher than the same indicators for non-folded yarns. Since the majority of manufacturers are focused on the use of non-glossy materials, the device may malfunction.

To eliminate the need to achieve the optimum angle of deflection of the thread. In extreme cases, you can slightly increase the course of the shuttle by creating an elevation on its hull. For this purpose, tin is applied using a soldering iron. They are soldered in the opposite direction to the needle, leaving a 0.8 millimeter gap between the elevation and the needle. Replacing threads with a better one can also help.

Nylon Thread Problems

The sewing machine the Seagull can pass stitches during the work with a nylon thread. This is caused by the special properties of the material, which can negate the friction with the needle. When the needle is lifted, the thread simply does not form a loop-inlet. Also, nylon can be deformed and reach for a needle. All this violates the natural process of work, creating faults.

This vulnerability makes it necessary to adhere to the following instructions for all models of sewing machines.

- It is necessary to switch to use thinner needles and threads.

- Adjust the gap between the needle and the nose of the shuttle to the minimum position.

- Adjust the plane of rotation of the shuttle and set the gap in it to 0.05 millimeters.

- Pay special attention to the quality of threads, use only professional threads from reputable manufacturers.

Virtually any device can be configured to work with nylon, but all manipulations can go to ashes if the quality of the thread is unacceptable.

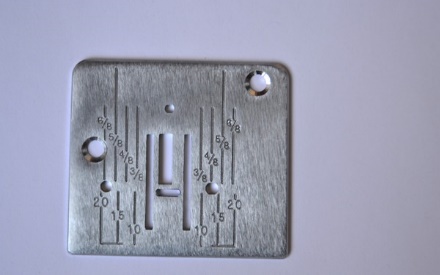

Wide hole of the needle plate

If the owner has repeatedly violated the rules for using the machine, do not be surprised at the rapid wear of some of its parts. For example, it is typical for “Chaek” to break a large hole in the plate with a needle. A needle carries along a thread when lifting, and that, in turn, does not have time to form a loop-puff enough to grip. This can only be fixed by replace the broken plate on a new one. We'll have to spend time finding the right part and putting it in place of the old one.

Twisted thread

In case of incorrect position of the thread or its twisting, the loop-inlet goes to the side. In this position, it deviates too much from the required angle of ninety degrees, and the shuttle cannot capture it. Breakdown will be eliminated if replace strings. You can also check the status of the entire shuttle mechanism and replace it in the event of a malfunction. This is an extreme measure, do not rush to acquire new parts. In most cases, breakdowns are perfectly repairable even at home.

These are the main reasons why a sewing machine sometimes skips stitches. Carefully check the status of the small elements of the device, because they are very easily damaged. Timely inspection will help to avoid serious damage.

/rating_off.png)