Is it possible to repair the sewing machine by yourself

Sewing machine is an indispensable unit for home sewing needlewomen. But sometimes the machine stops sewing normally: the thread breaks or gets tangled, a knock is heard when the machine is running. In this case, repair or adjustment of the sewing machine is required. If complex repairs with replacement of parts and assemblies and subsequent adjustment are required, then such work is better to be entrusted to a specialist. But most often the car starts to “be capricious”, because misuse, or if the rules of adjustment and adjustment specified in the instructions are not followed - in this case repair of sewing machines with your own hands is quite possible.

Content

Needle problems

The most important part of the unit, oddly enough, is considered a needle. During the service she makes hundreds of thousands of punctures, both thick and thin. Over time, the needle blunts, the load increases on it, as a result of which it bends and breaks.

If the needle hits a hard surface, for example, on the metal case of the unit or a button, then the tip can be bent. At first glance, the needle looks fine, but when sewing a flat stitch does not work. This is explained by the fact that when the thread passes through the eye of the needle, it clings to the defect of the tip. When this happens, it starts to slow down with the formation of a surplus of the upper thread, which runs in the stitch. For this reason, a break occurs periodically, and loops appear in the line.

Very often, the unit fails if the user tries to sew fabrics that are not intended for home appliances, for example, double twisting on jeans, lightning on a leather jacket, etc.

Thus, the entire repair of this unit may consist in a simple replacement of the needle. This part should be taken seriously and changed as often as possible, even if there are no visible defects on it. You should not throw in used needles: they can help you out if a good needle broke, but you need to continue sewing immediately.

Incorrect needle installation It can also cause the “vagaries” of the sewing device. This problem is often encountered when repairing Singer sewing machines (manually operated), as well as Chaika 100 and others.

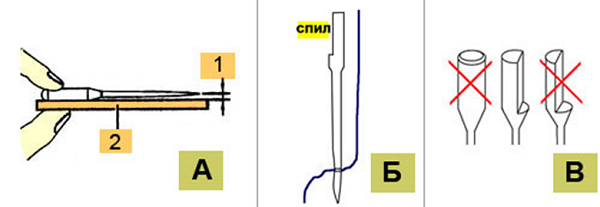

The needle blade must be turned towards the nose of the shuttle (fig. B). If the device confuses the thread, remove the needle and check whether it is properly fastened.

There are cases when a seamstress gets a part for industrial equipment instead of a needle for household machines, and installs it. Although confusing household (Fig. B) with industrial is difficult. On the household needle there is a small saw cut. When installing industrial needles can damage the shuttle, because some types of this part is slightly longer than usual. Even if its length is normal, the correct gap is still broken, which should be between the nose of the shuttle and the needle blade, as a result of which “gaps” appear in the line.

A curved needle can also be the culprit for skipping stitch. If you look at the picture (A), it is easy to understand how to check the curvature of the part. Since from the side it is difficult to determine the bending of the needle, it must be placed on a piece of glass.Turning a part, if it is not bent, the gap (1) will not change.

Unstable stitch

As noted above, repairing sewing machines with your own hands can be done with minor breakdowns that do not require replacement of parts in the assembly units.

You should know that preventive cleaning of the device and timely lubrication of moving parts can prevent most problems in the device.

If there are gaps in the line, then the following factors may cause this problem.

- The mount holding the needle loosened. To fix the problem, clamp the part with a screwdriver, key or pliers (depending on the model of the unit).

- The nose of the shuttle in the process of work was blunt or bent. To check this, use a magnifying glass. If a defect is found, replace the part with a new one.

- Needle too thick for fabric. Use the manual of the device, which describes in detail the criteria for the selection of fabric and needles.

- For a small needle needle, the thread is too thick. Choose its thickness corresponding to the size of the needle's eye.

- Incorrectly installed needle. Install the part as instructed.Usually sawd off on the flask should be directed away from the seamstress.

- Factory marriage needles. Replace it with a new one.

If the thread is torn

In some cases, malfunctions that can be resolved with one's own hands are associated with a broken thread (top or bottom), poor tissue advancement, or problems with a needle. In other cases, you must contact the master.

Remember that repairing sewing machines Chaika 142m, Phoenix or Podolsk with your own hands should begin with cleaning the unit from dust and lubrication of moving parts.

Upper

Constantly tear the top thread can, if tucked bad quality thread, or it is generally incorrectly filled. In different models of devices, the filling circuit may differ, therefore it is necessary to study the instructions, and according to it, insert the thread correctly. If the number of threads relative to the needle is chosen incorrectly, also use the manual. Also the upper thread breaks when the bobbin case is heavily spring is pressed. Loosen the adjusting screw slightly with a screwdriver. This adjustment is often done when repairing a sewing machine Podolsk, as well as Dragonfly, Brother, and others,since the bobbin cases in all models have a similar design. In addition, a broken thread may be due to improper installation of the needle.

Bottom

At the bottom of the unit, the thread passes the path, starting from the bobbin (small coil), through the bobbin case, and ending with the needle eye of the plate. Breakage of the thread may be due to its dense and uneven winding. Also need to check correct installation of the bobbin.

The quality of the thread plays an important role in the proper operation of the machine. If it is with hinges, it is inevitable to lock it under the spring, followed by a break.

Breakage of the lower thread occurs rarely, and this defect is noticed more often in machines with a vertical hook. Burrs can be formed on metal parts near the needle if the needle repeatedly deviates from its path. In most cases, it bends when the user drags the hemming material in order to “help” the typewriter to promote it. If you found burrs, they can be removed with fine sandpaper, then lubricate all moving parts of the assembly. After that, you should sew a small piece of cloth so that excess lubricant is absorbed into it.

There are cases when a seagull sewing machine is being repaired, or a Podolsk sewing machine is being repaired, as a result of which the incorrect location of the point through which the thread comes out of the bobbin case is detected. The problem is solved by replacing the “native” cap with a similar one produced by JANOME. This solves the problem with breaks, and also improves the quality of the seam.

Thread loop

Most often, the looping occurs from below, due to a weak upper tension of the thread, or careless refilling. In order to avoid this problem, it is required to set the foot of the machine in the lower position, and after that to lead the thread at all points of the refueling, referring to the instructions. When lowering the foot, the plates are closed. tension regulator.

The thread must be started with tension, which should be noticeable when the thread is pulled out, in order to thread it into the thread take-up.

If the thread in the plates is not clamped, it says that a foreign object has got into the space between them (a piece of thread) that needs to be removed. In the case when the cleaning does not help, you need to disassemble the regulator. In old-style units, it is located outside the front panel of the device.In new models of machines, you will need to remove the lining of the apparatus to get to it, for example, when repairing a sewing machine Chaika.

Poor tissue advancement

Frequent breaks and difficulty moving the fabric may be due to misalignment of the movement of the needle and the moving rod assembly. Since each model of the sewing machine can have a different setting for the knot, for example, if you take repair of Brother sewing machines, it is not possible to give universal instructions. But if you understand how this node works, then you can configure it on any model of the unit.

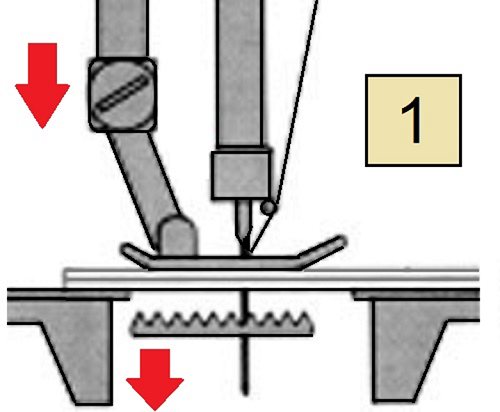

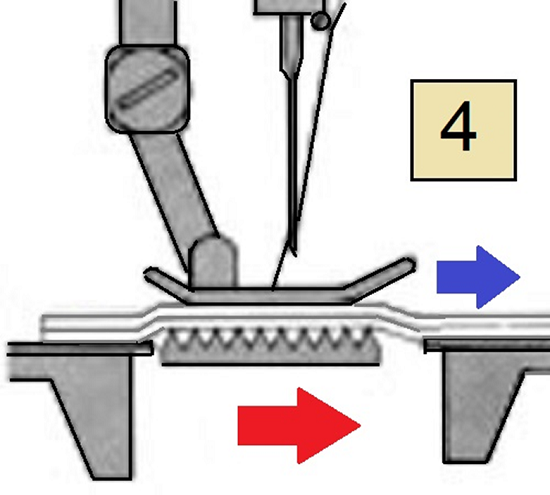

- The needle makes simultaneous movement together with the staff to the final lower position.

The most important thing in tuning is when the needle tip meets the notches of the slats. The latter should be in a slightly lowered state relative to the needle plate, but not completely (look out a little). At this time, the position of the needle should be such that its tip does not reach the teeth of 1.5-2 mm. This position of the two parts relative to each other is the main parameter when setting pryamostrochny type machines. In this case, your unit will no longer tear the thread,stop badly promote or collect fabric. This is possible provided that the other settings are correct.

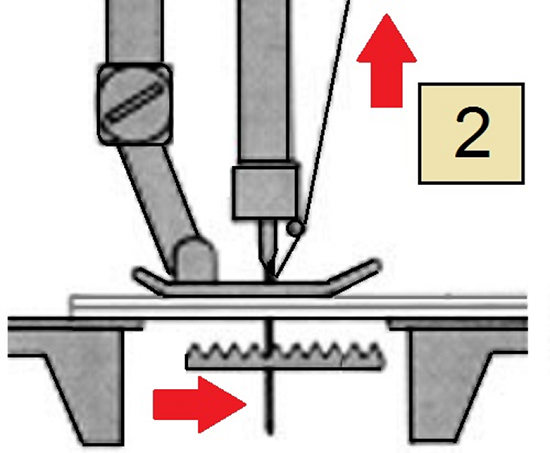

The most important thing in tuning is when the needle tip meets the notches of the slats. The latter should be in a slightly lowered state relative to the needle plate, but not completely (look out a little). At this time, the position of the needle should be such that its tip does not reach the teeth of 1.5-2 mm. This position of the two parts relative to each other is the main parameter when setting pryamostrochny type machines. In this case, your unit will no longer tear the thread,stop badly promote or collect fabric. This is possible provided that the other settings are correct. - The moment when the needle is raised. After reaching the lower position, the needle begins to rise, and the rake - moving forward to prepare for the next cycle, promoting the fabric.

At this time, a stitch is formed (with the help of the hook, the upper thread is removed from the needle), and there should be no obstacles for the thread to advance. Often this happens simultaneously with the advancement of the fabric, as a result of which excessive tension is created, and the thread breaks. Often moving the fabric contributes to the breakage of the needle.

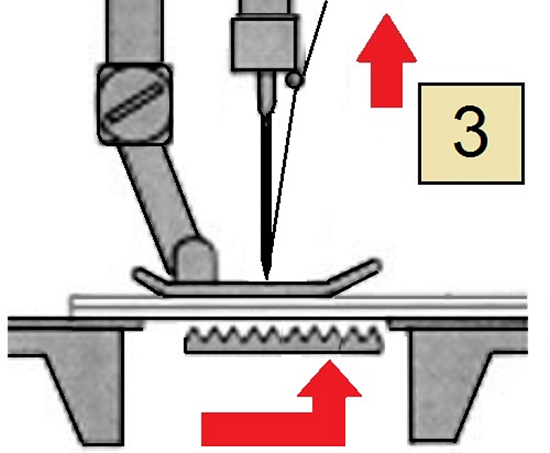

At this time, a stitch is formed (with the help of the hook, the upper thread is removed from the needle), and there should be no obstacles for the thread to advance. Often this happens simultaneously with the advancement of the fabric, as a result of which excessive tension is created, and the thread breaks. Often moving the fabric contributes to the breakage of the needle. - The thread is tightened in the stitch. If the rail moves upward towards the plate, the yarn feeder pulls the upper thread in a sharp movement. This movement of the yarn feeder should occur when the stitch formation has already ended, so the excess thread is pulled out.

The quality of the stitch is influenced not only by the tension of the thread, but also by the correct operation. compensation springs, the ideal state of the shuttle (without roughness and burrs), the force of the thread tension below and other parameters. If the rail is not set up correctly, the thread will get tangled from the bottom, break off and stretch with difficulty.

The quality of the stitch is influenced not only by the tension of the thread, but also by the correct operation. compensation springs, the ideal state of the shuttle (without roughness and burrs), the force of the thread tension below and other parameters. If the rail is not set up correctly, the thread will get tangled from the bottom, break off and stretch with difficulty. - Promotion of the fabric. At the last stage, the rake begins to advance the fabric over the plate. The stitch length set by a special knob depends on the distance the rake moves. Attention should be paid to the height of raising the teeth above the plate. Their departure should be no more than their size.

For thin tissues, it is recommended to lower them by half, with a simultaneous decrease in the clamping force of the foot. The ideal option can be called rail replacement on the other, with smaller teeth (not all sewing machines have such a possibility). Straight-line units can sometimes have 3 types of slats, and, accordingly - needle plates. The rake changes simultaneously with the plate with the corresponding number.

For thin tissues, it is recommended to lower them by half, with a simultaneous decrease in the clamping force of the foot. The ideal option can be called rail replacement on the other, with smaller teeth (not all sewing machines have such a possibility). Straight-line units can sometimes have 3 types of slats, and, accordingly - needle plates. The rake changes simultaneously with the plate with the corresponding number.

Drive Malfunction

Some models of sewing machines are equipped with an electric drive, which is designed to rotate the main components of the mechanism. Electric drives often fail due to overheating during hours of operation of the unit. When this happens, the motor overheats, the conductors melt, and the windings close. In this case, the repair of a blown electric sewing machine is not appropriate. It will require a complete replacement of it with a new one.

Also a sign that the electric motor will soon blow, can be called a slowdown in the operation of the device and the appearance of the smell of burning electrical wiring.

Pedal breakage sometimes taken for the failure of the motor. Therefore, it is necessary to disassemble it and inspect it carefully for troubleshooting. If you can not repair it, you will need to purchase and install a new pedal.

In conclusion, we can say that the sewing machine is a rather complicated mechanism. Because of the complex structure, there is a mass of breakdowns, which can be eliminated only by a qualified master. In addition, the correct operation of the sewing machine is influenced by the professional tuning of some of its knots, which cannot be adjusted with one's own hands, without special knowledge.

/rating_off.png)