Why the sewing machine tears the thread when working

One of the most frequent questions asked by sewing lovers: why does a sewing machine tear the thread while working? It is important to note that such a malfunction occurs on both manual and electric sewing machines, and the methods of repair in any case will be the same. This problem can cause many reasons, among which are:

- poor quality thread;

- improper installation of the needle;

- breakdown of the tension regulator.

Content

Poor quality thread

A frequent cause of a problem, when the sewing machine starts to tear the upper thread, may be too much tension of the regulator or poor quality thread, if it is constantly twisted in the regulator. Replace poor quality thread that will not have visible defects in the form of small nodules and other damage, and the problem will cease to bother you.

When the upper thread is stretched too tightly or too loosely, the machine either tears it or pulls it into the shuttle slot. Adjust the tension force You can use the control nut on the regulator.

Incorrect needle installation

Proper needle placement suggests that its long chute is directed toward the thread guide. When doing so, always pay attention to matching yarn thickness and needle size. The yarn should pass through the needle freely and not form small clumps. If this happens - use a needle with a large diameter of the ear.

Too sharpened hole in the needle may well cause the thread to break. Pay attention to the sharpness of the needle's eye, and if the problem is in this, sharpen the cutting edges with a file or emery paper.

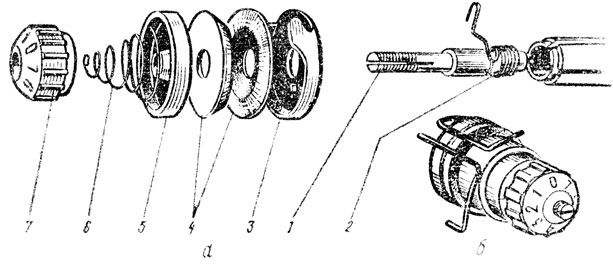

Breakdown of the tension regulator

If your sewing machine has recently been repaired, perhaps taper spring In the process of repairing it was not collected correctly, which was the reason for the thread breaking. To solve the problem it is necessary to rebuild the regulator. For this:

- remove the clamping nut;

- scroll the spring one full turn clockwise;

- Install the nut to its original position.

It is very important to pay attention to the position of the spring. It should be positioned so that its wide end is located deep in the body of the machine. If this condition is not fulfilled, the spring bar will not be able to freely rotate around its axis, and it will be impossible to adjust the tension of the thread.

Sewing machine regulator device

If the spring does not roll and jams when rotating, straighten the upper barb of the conical spring so that the upper thread moves freely.

Other reasons

Among other reasons that can trigger such a malfunction may be the following.

- Incorrectly filled shuttle. Make sure the cars shuttle is filled correctly. Otherwise, the lower thread will be fed in the opposite direction, which will lead to deceleration and, as a result, break of the lower thread.

- Bad lubrication. A simple lubrication of the working parts will help make the machine not tear the sewing threads.

- Too strong hold on the lower paws may affect the quality and speed of your sewing. On some models there are three modes that correspond to the type of fabric with which the seamstress works: thick fabric, light fabric and embroidery mode.You should choose the one that best suits the material used.

- Notches. Due to prolonged use, various notches appear on the surface of the sewing machine. Most often such damage occurs at the edges of the needle plate. You can solve the problem with the usual polishing surface.

If you are unable to solve the problem yourself, contact the master. Perhaps the reason lies deeper, and you want to replace parts that work malfunctioning.

/rating_off.png)