Oil heater do it yourself? Easy!

The self-made heater can be successfully used in places with reduced design requirements. Garage, cottage - the most suitable for this room. Consider how to make oil heater do it yourself

Content

Making a garage heater

To maintain a comfortable temperature in the garage is not difficult to make the heater itself. waste oil. At the same time, the problem of its disposal will be solved, which is also a pressing issue for car owners. For its assembly almost all elements and spare parts can be found in the same garage.

In the manufacture of the heater will need:

- metal pipes;

- TEN (heating element);

- waste oil;

- wire with a plug.

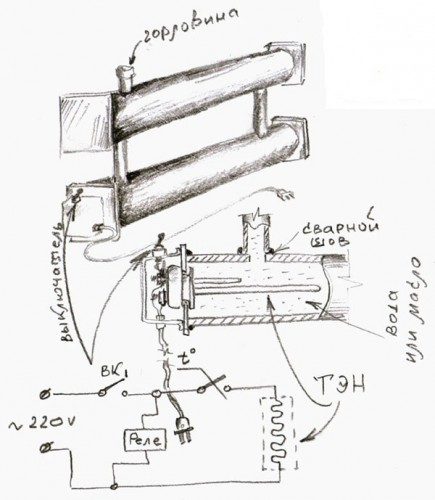

Structurally, the body can be made in any form that is convenient for placement in the garage. The photo shows one of the possible schemes of the device.

Scheme homemade heater on oil

Metal pipesused any diameter. It must be borne in mind that the thinner they are, the more they will be needed. The temperature of the room will depend on the area that gives off heat. The length of the pipes is also arbitrary, it is desirable that it be maximum, but at the same time perfectly harmonized with the size of the wall, which will be installed. The metal from which the pipes are made is not significant. The wall thickness of the pipe can be any.

Heating element selected by power and voltage. Practice shows that 1.5-5 kW of heater is enough for heating. Here it is necessary to take into account that the comfortable temperature of the garage and the apartment differ significantly. And such a wide distribution of power is given on the basis of the size of the heater. The voltage for connecting the heating element is taken standard - 220 V. (other parameters are not considered here).

When choosing a heating element, you need to consult an electrician on this issue.

Used oil.Most motorists almost 2 times a year, change the oil in the engines of their cars on their own. Therefore, working out, as a rule, is available for everyone. It remains to collect the right amount and begin to manufacture the heater.

Before pouring the used oil into the system, it must be carefully filtered.

Stand making

The stand is made of metal angle or profile. Dimensions are based on the total size of the heater. For its manufacture will need a welding machine and an electric grinder - "Bulgarian". From the corner or profile cut elements of the future stand. Its form is also arbitrary. It is only necessary to take into account such a moment as ease of disassembly. It is possible that there will be a need to disassemble the heater. For example, in the spring, when it is no longer needed.

Before you start making the stand, you need to draw its scheme, determine the size and prepare the workpiece.

To do this, grinder gently cut the desired number of corners and grind their edges. It remains to "cook" cut according to the scheme of the workpiece. After welding, the seams are cleaned, and the stand is prepared for painting.

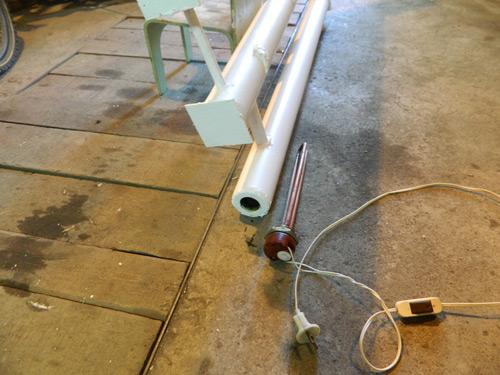

Work with pipes

After the oil heater circuit is selected, it is necessary to manufacture it. case.Make a drawing, determine the size and begin to work as a grinder. Pipes are cut to length in the right quantity. After stripping the ends, they are carefully and carefully welded. The quality of the welding will depend on the work of the heater as a whole. Leaking seam - not only a nuisance, but also a possible cause of the fire. When brewing the pipe ends, leave one (on the lowest pipe) free. Subsequently, the heating element will be inserted into it. This means that the stub will be a different configuration.

Finished pipes are tied together. Piping is done with pipes, only of smaller diameter. At the very top of the pipe, you must provide a place where there will be a filler plug. Structurally, it can be made in the form of a welded short sgon with a clutch, one side of which will be welded. Using your fitting and mechanical experience, the configuration of the heater can be made more aesthetic, unlike the one in the photo. By the way, the body can benot only tubular. For this purpose radiators from automobiles, old cast-iron radiators and other closed containers will do well.

To increase the safety of work, it is advisable to install a pressure-sensitive safety valve on the upper pipe.

Installation of heating elements

The electric part of a homemade heater is quite simple in design. Heater, connecting wire with plug - that's all that is needed for its installation. To begin with, the grinder cuts a plate of metal to which the heater will be attached. An hole is drilled or electrically welded in it according to the seat and fixture of the heater. When this part of the work is done, the plate is welded to the left for this purpose. end of the lower tube. After processing of welding seams TEN is established on the place.

The gasket between the heater and the heater body is made of thermo-oil-resistant material (special rubber). Electrical connecting wire is quite suitable from the old electric iron. At this assembly of the heater on the waste oil with their own hands can be considered complete. It remains to fill the coolant and turn on the device in the network.

The oil in the heater is poured in the amount of 85% of the internal volume of the heater.

Improve the homemade heater

If a similar design of the oil heater is planned to be used in another place, for example, in the country, then it will have to make some changes. They will only touch electric part. The fact is that in the garage you are temporary, but in the country, compared to the garage - all the time. Therefore, the requirements of the room temperature will be different.

To achieve comfortable conditions for heating a country house, the electrical circuit of the heater should be slightly modified. To do this, the circuit TENA is entered relay, which will control the heating element, to maintain the specified temperature of the coolant. And again the old electric iron, more precisely its bimetallic plate, can play its positive role. In the iron, it served as a regulator of its heating, here its purpose will be the same - to maintain the desired temperature of the oil. In addition to the direct there will be an additional effect - energy savings.The dependence is direct - the lower the temperature, the less electricity is consumed.

Bimetal iron plate

If a large amount of heating is planned (for example, a greenhouse), then several heating elements can be mounted in the device.

The self-made engineered oil heater completely replaces the purchased one, and even surpasses it in some parameters. This is, firstly, the manufacture of the desired size. Secondly, tangible savings in material resources. Equally important will be the fact that the garage is a bit cleared of unnecessary rubbish (pipes, trimming angle, profile), which will be made useful and necessary thing.

The video shows the manufacture of a slightly different model of oil heater.

/rating_off.png)