Why the gas stove flowed

Geyser, or as it is also called, instantaneous water heater, has become quite a popular household appliance among the owners of private houses. A relatively small unit is able to provide several rooms with hot water. A plus of the device is also the absence of the need for a storage tank, since the system is designed to warm the water directly during use. But, like many home appliances, the water heater is prone to breakage and malfunction. What if, for example, a gas column flows, and why does this occur?

Content

Main types of faults

If even insignificant deviations occur in the operation of the instantaneous water heater, it is necessary to diagnose the efficiency of its systems. The cause of the problems may be hidden in the following.

- The insulation of the connecting parts is damaged.. It is necessary to disassemble and replace all components that are responsible for tightness during water supply and intake. As a rule, these components are located between the pipes and the main pipes. All rubber gaskets and liners are subject to normal wear, experts recommend to replace them every two to four years. In addition, leakage can be prevented with sealants. Treat with a special compound all the compounds responsible for transporting the liquid.

- Problem may occur due to disturbance of the heat exchanger surface. This detail performs the functions that consist in the warming up of running water. The connecting pipes that feed the liquid from the water supply, as well as the gaskets, eventually wear out. This leads to corrosion, microcracks and deformations, through which water seeps and drips from the column.

- Lack of regular check-ups may also cause gas to flow. As mentioned earlier, gas equipment needs special care and periodic inspection.This procedure will help to avoid serious violations and prevent unplanned shutdown of water.

Elimination of leaks

Having identified the source of the leak, it is necessary to proceed to its elimination. The sequence of actions will depend on the design features of each specific model and the segment subject to malfunctions.

Radiator leakage

Green spots on the surface of the protective layer can be a sure signal that a microcrack or deformation has formed on the radiator housing.. They occur due to high humidity, which does not have time to dry out. To eliminate the malfunction it is necessary to follow the following guidelines:

- Turn off the water supply using the riser water pipes, it is necessary for further work with the column. After that, disconnect from the gas column hoses and nozzles for the intake and transportation of fluid. Drain the radiatorby removing the remaining cold water from the shallow ducts. Some difficulties may arise with the coil, use a special pump for pumping fluid. If you don’t have the right tool at hand, you can use a vacuum cleaner with a backdraft.

- After the procedure of drainage, proceed to the cleaning of rusted or covered with green areas. Using a fine sandpaper, remove all dirt from the surface, then wipe them with a special solution for degreasing and wipe with a dry cloth.

- For the next step, arm yourself with a soldering iron and a sufficient amount of solder. The tool should be designed for use at a temperature of one hundred and eighty degrees, and its power should not be below one hundred watts. Crumble a small amount of rosin. If the farm did not find the right amount, you can use aspirin: crush into powder one pill. Process the resulting substance work surface.

- Heat the soldering iron to the required temperature, and then proceed to the solder soldering. Lift its layer two millimeters from the surface.

- The operation must be repeated for each microcrack or through the deformation section.

Upon completion of soldering work, allow the solder to cool completely and reassemble the gas column in the reverse order. Do not forget to run it in test mode before starting full operation.

Experts say that such measures are temporary. Sealed pipes can be used only as a replacement, because the damaged surface will be vulnerable. In the near future, try to replace worn parts with new ones, or make a rule to regularly clean and strengthen damaged surfaces.

Leakage Threaded Connections

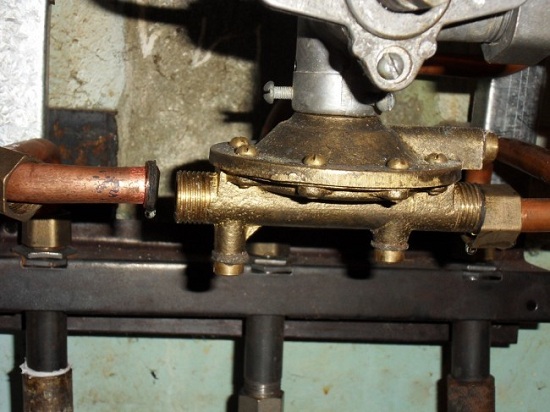

It is not uncommon for a leak to be found between the individual elements of the instantaneous water heater connected by threads. On examination, it is necessary to find out exactly which water is dripping from the nozzle. The left tube is responsible for the supply of heated fluid, the right one is used to transport fuel. In most cases, the droplets are formed on the water pipe - this is due to the wear of the gasket. Replace this item is not difficult, even at home.

- Before proceeding with the repair, block the flow of cold water from the water supply system.

- After that, carefully disassemble the connections in which the failure was detected using professional tools. Remember that you can not carelessly refers to the details of the gas column. Remove the gasket.

- All elements of the connection and the thread must be cleaned of accumulated rust and dirt, then degrease and wipe dry.

- Replace the rubber gasket with a new one and assemble the assembly in the reverse order.

It happens that the thread of the fastening nut deteriorates or breaks. In this situation, you must purchase a new one. They are sold in specialized stores or from the official dealer of the supplier’s company.

Pipeline leakage

If all the procedures are completed, and your gas column is still flowing, it's time to pay attention to the pipes. Not only the connecting elements and the radiator are subject to wear, but also the pipes for the delivery and collection of fluid. Having identified the problem and found a microcrack on the surface, do the same procedure as with the radiator, namely, clean the rift and seal it with solder.

According to experts, this is the best way for immediate repair. However, without proper care, these patches will soon leak again, so do not delay with the purchase of new connecting materials.

In addition, due to inexperience, you may be late with repairs, and the fault will irreversibly destroy the pipe.It is useless to solder such parts, as soon the crack is spreading on the untreated surface. In this case, you will have to immediately replace all the parts to prevent serious damage to the column.

Users who encounter this type of failure share their experience in finding the necessary materials. According to them, it is almost impossible to find pipes from the manufacturer, even highly specialized shops cannot always provide such goods. The fact is that manufacturers do not supply spare parts, and they have to be replaced with universal corrugated hoses.

Now you have some idea what to do if a gas column flows. Many damage can be easily repaired without causing a wizard. But only a competent specialist will be able to give a technical conclusion about the safety of equipment operation. Carefully handle the gas appliance, and it will serve you for many years.

/rating_off.png)