Why the gas column slams when turned on

It is necessary to handle gas equipment very carefully. This statement applies to even the most familiar devices, such as instantaneous water heaters. After a long time, working with equipment becomes familiar, and many owners begin to neglect the simplest rules of safety. Such behavior is not acceptable, because irresponsibility can lead not only to serious damage, but also life-threatening injuries. It is extremely important to monitor any, even the most insignificant, changes in the operation of a gas device, in particular, it concerns unusual sounds. If the gas column is switched on with cotton or makes noises, immediately contact a specialist in repair.

Common Damage

Malfunctions in which the gas column claps during operation are typical of previous generation models. Some of the shortcomings of their design with time led to a similar effect, seriously disturbing the owners. For flow heaters new generation such problems are not typical, and they occur very rarely.

The same sound, reminiscent of cotton, arises from the gas accumulated in the heat exchanger. Over time, a minor problem can turn into a serious problem. The gas will begin to collect in the gas pipe, then it will take a chimney - no need to describe what the consequences may be. Therefore, when you first hear the clap, do not pull with the call of the master.

In most cases, gas accumulations occur due to:

- chimney blockages that make it difficult to pull;

- a broken valve that makes ignition difficult when switched on;

- deflected light ignition wick - this problem most often occurs in columns with piezo ignition.

When used modern model instantaneous water heater with built-in automatic ignition function, breakage provocateur may become:

- consumed battery in the control module;

- broken microswitch in the water node;

- defective spark plug;

Repair of gas appliances requires special attention and extensive experience. Contact a qualified repair technician before attempting to fix the problem yourself.

Diagnostic method

Having decided to carry out repairs themselves, the owner must adhere to the instructions exactly. First of all, experts advise to check chimney draft intensity. The main part of the geysers is equipped with a casing that has holes provided just for this procedure. If the manufacturer of the column has not made such holes, the craving can be checked right next to the gap located at the smoke hood. In addition, the draft is perfectly felt at the hatch for cleaning the chimney.

Usually a lighted candle is used for this procedure: it is necessary to carefully follow the deflection of the flame. If it led to the side, then the chimney works well, and the draft is normal, if the light burns unevenly and only deviates slightly - weak. Traction may not be at all, then the tongue of flame will burn exactly.This means that the chimney is closed, and the use of a gas column can be dangerous.

Auto Ignition Column

Gas equipment, equipped with a special ignition system when turned on, saves the owner a significant amount of gas. The ignition device is controlled by an electronic control module, which is directly connected to the microswitches. They are mounted on fluid and fire regulators. As a rule, this system does not fail and is considered one of the most reliable, however, costly repairs in the event of a failure can be a significant disadvantage for the owner.

Group of ignition Neva Lux 5514

Faced with a problem in such a column, no need to panic. First you need to establish the severity of the breakdown and decide whether to call the master or the malfunction can be corrected yourself.

- Explore battery chargepowering the control module. A spark that does not arrive in time, which leads to a delayed ignition of the gas, may be caused by a low battery charge. To solve this problem is quite simple - replace the power supply with a new one.

- Rate this operability of a microregulator of fluid pressure. This device is provided by manufacturers in order to send signals to the control module. Its activity occurs during water supply, when it becomes necessary to ignite a gas. Like other sensors, the micro-pressure regulator can fail and give incorrect commands when water enters. Device problems are detected by a multimeter or ohmmeter. If, after measurements, the indicators on the display do not correspond to the norm, then a breakdown has occurred in the system. You should immediately replace the worn part with a new one.

- Check out location of the gas igniting device. This device is at risk of deformation due to high temperature or temperature gradient. Installing the item in the correct position is quite easy, because it is held by one screw. This screw should be loosened a little, and the position of the ignition plug should be straightened so that the spark gap is about 0.40-0.50 centimeters. Make sure the ignition takes place the first time.

- To study flame retardant performance. Often, gas accumulates due to a faulty valve that slows down the flow of liquid.It may break or have an incorrect setting. The described part is made in the form of a small metal ball, partially blocking the conductive valve in the water pressure regulator. A workable ignition retarder has no fixation and moves freely under the cover. If the ball stalled, you can attempt to move it from place with a flexible cable that is passed through a hole in the channel. You can also try to clean the channel from pollution, but this should be done carefully. Experts do not recommend carrying out the procedure without valid need.

Having completed the repair work, be sure to check the connections for tightness. For greater safety, they can be sealed with rubber gaskets or special sealants.

Lights Wick Column

The past generation of instantaneous water heaters "loved" to slam when turned on. Their design today is considered unsafe and less convenient compared to advanced devices. However, the repair of such equipment was much cheaper.

The most popular reason for gas accumulation in unallocated spaces is the wrong location of the pilot wick. This results in a reduction in the flame, unable to reach the edge of the burner edge. All this is caused by an insufficient amount of gas supplied to the wick. The root of the problem is usually clogged jet.

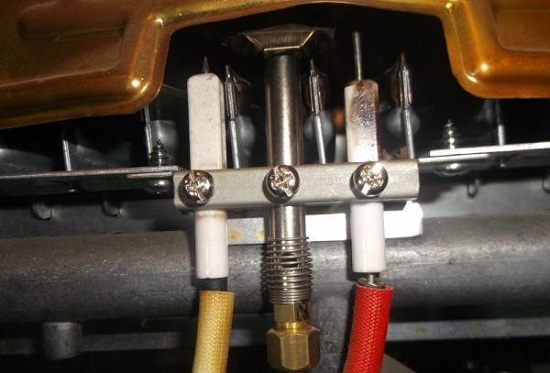

Brass jets from which gas enters the burner

You can resolve the problem at home, but it will require complete disassembly of the device. The main part of instantaneous water heaters is arranged according to the same type of scheme, therefore the instructions for the procedure will not be much different. It is necessary to act as follows:

- shut off the gas and water supply;

- dismantle the protective casing of the column;

- provide free access to the ignition wick tee;

- loosen the mounting screws of the guide tube, and then remove the nuts securing the thrust sensor and feed tubes;

- gently pull the tee out of the slot intended for it;

- Having examined the lower pipe, you will find a small screw with a through hole - this is the jet;

- remove the part from the tube, clean it with a thin wire or needle;

- reassemble the column in the reverse order.

Upon completion of the procedure, the water heater should turn on without a pop.Finding out why your geyser sometimes turns on with cotton, correct the problem. In the case of complex damage, contact a competent specialist.

/rating_off.png)