How to repair starter trimmer

Repair starter gasoline trimmer may be required at the most inopportune moment. In this case, the problem can be solved in two ways: replace the broken part or change the entire assembly. The last option is more expensive. To repair the device with your own hands, in most cases you will need only a screwdriver with a corresponding tip from the tools. Repair work does not take a lot of time and does not require special knowledge. It is enough to know the device, the principle of operation, the nuances of assembly and disassembly of the starter on the trimmer, in order to achieve the desired positive result.

Content

The device and the principle of operation of the starter on the trimmer

Gas engine - this is, in principle, the main part of the mowers. Its power lies in the range of 0.5-2.5 hp. Movement from it is transmitted to the shaft inside the hollow rod, and then through the gearbox, consisting of gears, already a fishing line or knife (working body).

Also benzokosy have the following elements:

- protective casing;

- lever;

- belt designed for ease of use of the device;

- A starter used to start a gasoline internal combustion engine.

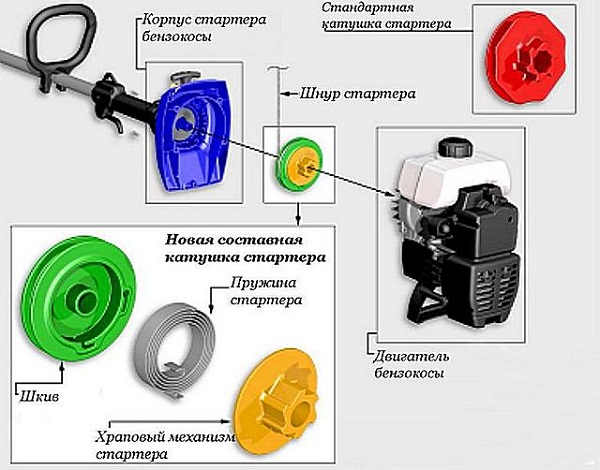

All the details of the motokos are presented in the photo below.

The starter on the trimmer is an integral part that performs the engine start-up. He is depicted separately in two photos below.

Starter mechanisms of various models of benzocos work on the same principle: During the start of the engine, the protrusions marked in the photo above with the number 1 enter the hook with the pawls 3. When the engine starts to work, they return to their previous position due to the influence of centrifugal force. A similar role is also played by wires 2.

The process of returning to the initial position of the elements of the mechanism occurs due to the presence of a spring twisted around an axis.She turns around when they pull the rope. After releasing the cord, it is pulled in and wound up due to the folding of the spring. During the start of the internal combustion engine of the benzocos, the triggering mechanism rotates its shaft before it starts working (starts).

Today, gasoline mowers equip Starter mechanisms of two types:

- manual;

- electric.

The first option is much more common.

The starter on the trimmer can function without damage for a long time. Definitely indicate the time of failure is impossible. Everything is determined by the initial quality of the device and the observance of the rules for handling it.

The main malfunction of the starter trimmer

Determining the cause of the breaker trigger is easy. There are several basic options:

- broken cord (rope);

- when the spring breaks or goes out of engagement.

The details shown are shown in the photo below.

It may happen that the starter mechanism is accidentally broken. The consequences will be deplorable if a torn rope is wound around the flywheel of a working internal combustion engine: then the spring will burst and the pulley will be torn.But such cases when full replacement of a starter knot is required, occur extremely seldom. In most cases, to fix the mechanism, it is enough to put a new spring or replace the cord.

Removing and disassembling the starter, replacing broken parts

To repair the trimmer starter, you will need to disassemble it first, and then assemble it. This process is not particularly difficult. For work you will need screwdriver with the tip of the desired shape.

Everything should be done carefully, observing safety precautions, mainly so that the spring does not injure the master in case of accidental departure.

Parsing starter knot

Disassemble the startup mechanism in order to install new parts instead of broken ones in the following sequence:

- using a screwdriver, unscrew the screw that secures the pulley with the starter cover;

- take out the spring and antennae;

- remove the pulley carefully (at the same time it is necessary to turn the head or to work, having previously worn glasses and gloves);

- determine why the launch mechanism broke;

- if the spring has collapsed almost completely, then it is replaced;

- when the spring comes out of the hook, it is set to its original place,having folded the antennae before this (the photographs show the laying process);

- after the spring plate is installed inside the groove, it is carefully twisted.

In order to change the spring, it is necessary to work carefully and carefully: it can, under the influence of the force caused by installing it in place, accidentally burst. Even if you carefully remove the roller, the springy strip very quickly flies off the coil and can injure your arm with its sharp edges.

Immediately put in place the spring plate does not always work. It often slips, so attempts are required to be repeated until the desired result is achieved.

Starter assembly

The assembly of the starter unit is carried out in a number of stages:

- the coil is turned over, setting it so that the spring bend fits exactly into the groove of the case, as in the photo below;

- two washers are placed between which a spring is placed;

- put in place a cup with mustaches;

- tighten the screw (photos below).

When making the above manipulations, it is imperative that put two pucks. If this is not done, the spring will eventually damage the plastic cup, and when it is tightened, wedging will begin.Because of this, it feels like a spring has flown away. To eliminate this drawback, you need to install this item of greater length or an additional washer.

When these parts are missing, you can just slightly unscrew the screw, and the starter unit will start working without shimming. But this option is temporary - it is better to repair quality as soon as possible.

Spring tension

After installing the spring should be tightened. To do this, perform the following steps:

- remove the handle from the starter cord;

- then the rope is inserted into the reel groove;

- make the spring tension, rotating the coil in the opposite direction clockwise (winding);

- make the required number of revolutions indicated in the instruction manual for the trimmer model used and corresponding to the length of the cord used;

- at the very end, the rope is passed through a hole intended for this, located in the starter cover;

- put the handle in place, fixing it with a knot.

If after repair the spring continues to fly, you can get rid of it in the following ways:

- Squeeze a suitable piece of the plate into the groove at the location of the spring hook;

- drill holes from the two sides of the groove in the coil into which to insert the spring hook and fix it with a wire.

Replacing the torn cord

Torn rope is replaced in the following sequence:

- old cord is removed;

- choose a suitable rope size (thickness and length);

- threading it through a special hole in the coil, tie a knot;

- cocking the spring, producing the required number of revolutions;

- fix the handle.

It is better to stretch the spring plate together with a partner so that the edge of the cord does not coil inside the starter mechanism.

Assembling the starter on the trimmer and winding the spring is easy, but you should do it carefully and with care. For different models of benzocos, the breakdowns of the triggering mechanisms are the same, so they are repaired in the same way. In this case there are some nuances associated with their design features.

/rating_on.png)

/rating_off.png)