Repair and lubrication of the gear trimmer

With frequent, intensive use of mowers, the gearbox may begin to warm up or make sounds uncharacteristic of its normal operation, for example, a gnash. This indicates that the mechanism must be lubricated. If this is not done on time, more serious problems will arise (for example, the gears will wear out quickly and you will need to replace them), up to jamming. With the gear mechanism there are also other breakdowns. Repair and lubrication gear can be done independently - for this you just need to familiarize yourself with the features of these works and stock up on some of the available tools.

Content

Trimmer gear unit

A trimmer gearbox is a knot that transmits the rotational movement of the motor shaft to a knife or fishing line. It is located at the lower end of the motokos rod. The gear unit is also designed to reduce the speed of the trimmer motor.

The mechanism depends on the model of the motokos of several gears rotating at high speed. As a result, they heat up due to strong friction. If there is not enough lubrication, or there is none at all, then the process leads to severe overheating and failure of parts, and, accordingly, the need to carry out complex repairs.. To prevent this from happening, the transmission unit should be lubricated in time. The disassembled gearbox is presented in the photo below.

Disassembled gearbox

Gearboxes of modern trimmers of different models from different manufacturers differ from each other in design and size seat. It happens:

- round;

- in the form of an asterisk;

- square.

The most common diameters of round seats are 24, 25.5 and 26 mm.

Motokos equip gearboxes with different types of gear:

- conical;

- worm;

- spiroid;

- cylindrical;

- planetary;

- wave;

- combined.

The drive shaft and gearbox are heavily loaded trimmer assemblies that are highly susceptible to wear. Between them, the movement is transmitted due to the adhesion of the gear teeth, located at different angles to each other. Effectively gear only works if there is no mechanical damage. In this case, the mechanism should not overheat, otherwise it may jam.

Main gearbox malfunctions and ways to eliminate them

With the gearbox of an electric or gasoline trimmer various failures occur. The most frequent of them are presented in the table below. You can also find the causes of their occurrence and methods of elimination.

| Gearbox malfunction | Possible causes of failure | Remedy |

| the transfer unit is hot | use of unsuitable (low-quality) lubricant or lack thereof | need to replace or add lubricant |

| gears new and not got used | should be run for a short time without heavy loads with regular stops, so that the mechanism has time to cool | |

| shaft jamming during rotation, backlash and knocking | destruction or significant wear of any of the bearings | replace the failed bearing with a new one |

| the gear mechanism flies from the bar of the motokos or staggers | damage to his body | it is necessary to replace the part |

| in some cases, with minor damages with a collar made of metal, the place with a break is tightened | ||

| not fixed on the tube | dock wear | you can make a winding of insulating tape in the place of attachment or change the barbell |

| the output shaft with a knife does not rotate or stops in case of increasing load | tooth wear on gears of either of them | replacement of an interacting pair of worn parts is required |

Bearings are destroyed due to the use of unsuitable lubricant or because of its absence. Also, their damage causes severe operating conditions motokosy and hit of foreign particles of a material (for example, the broken metal teeth of mechanical transfers) because integrity of anthers is broken.

To remove the bearing, you need to disassemble the gearbox and use special puller. If not, then you can try to do it with a hammer with a preset.In this case, work should be done carefully so as not to damage the seat. Using the pre-heating method for shooting the bearing is not recommended. This is due to the fact that the metal may lose the required performance characteristics.

If the knife ceases to rotate under load or even stands still, this is accompanied by an uncharacteristic sound.

Most of the problems of the gearbox can be easily fixed by hand. Replaced parts are encouraged to purchase "native", designed for the model used motokos.

Trimmer gear lubricant

Gear lubrication should be carried out regularly in accordance with the recommendations set out in operating instructions used model. This should also be done if:

- new gears were installed;

- atypical sounds from the gearbox during trimmer operation;

- knives spin hard.

In addition to the gearbox, it is also necessary to regularly lubricate the trimmer shaft. This is the norm for proper care of the device.

With constant use of a trimmer, its gear mechanism is under pressure from grass stuck to the knives, dirt, or due to a change in torque.The lubricant must be of high quality in order to extend the life of the gearbox.

Used types of grease

When choosing a lubricant, you must consider the following factors:

- the degree of adhesion of the composition with the metal node;

- product brand;

- lubricant consumption by gears.

Famous manufacturers, for example, Stihl, Husqvarna and others, except for trimmers, release and lubricant to them. Such products not only reduces wear, but also protects the metal gears from corrosion. Therefore, for motokos from these brands, it is better to use their own lubricating products.

If the composition used for lubrication has good adhesion, then it is practically not squeezed out of the reducer through the gaps.

Different models of grease consumed in different ways. This is determined largely by the intensity of the use of motokos and the heating of the transmission mechanism. It is considered that a lubricant is sufficient if the temperature of the gearbox during operation does not exceed 40 ° C.

For consistency, trimmer lubricants can be:

- liquid;

- semi-fluid;

- hard;

- plastic.

In terms of composition, the following types of lubricants are in demand:

- graphite, significantly reducing friction, resulting in improved gear rotation;

- lithium, which is also an excellent anti-corrosion composition, saturated with additives that increase the wear resistance of the metal without harmful substances;

- universalcontaining highly refined mineral oils and performance-enhancing components.

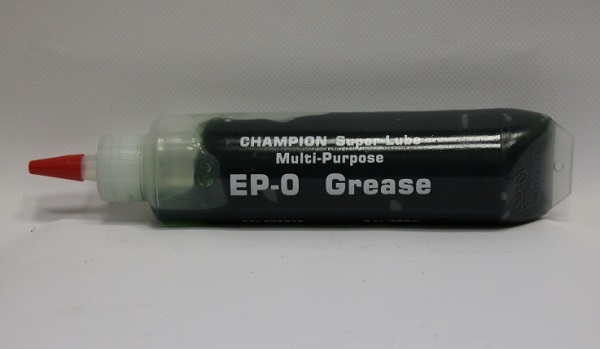

Examples of suitable lubricants are: Champion EP-0, Gear Grease OREGON, Oleo-Mas, Azmol 158, Litol -24. You should also pay attention to the advice of manufacturers on this issue and use the materials they offer. You can buy them in specialized outlets.

Champion EP-0 grease universal 120 gr

Algorithm of self-lubrication gear

To carry out the lubrication of the transmission mechanism of its preliminary disassembly is not needed. A special hole has already been inserted into the device for this purpose (it is shown in the photo below). In addition to gears during lubrication, attention should be paid to the following elements of the mechanism:

- bearing assembly;

- flywheel and doggie coil starter.

Grease insertion hole

Fill the oil or apply a solid lubricant through the grease box, closed with a screw.At the same time perform the actions in the following sequence:

- the gearbox body is cleaned of dirt and adhering grass; the area around the stub is especially careful so that the debris does not get inside the mechanism;

- using the appropriate tool (often it comes with a trimmer) unscrew the plug;

- the selected lubricant is introduced into the open technological hole from a tube, or using a syringe, as shown in the photo below;

- screw the cork in place.

Gear Lubrication

When making lubricant, you need to rotate the knife so that it is evenly distributed over the teeth of the moving gears.

If for any reason the gearbox needs to be disassembled, then the old lubricant must be completely removed from the entire surface of the gears and the housing, shaft, and only then use a new one. The disassembled mechanism is conveniently lubricated with solid compounds.

The whole process of gearbox lubrication is demonstrated in the video:

It is required to lubricate the transfer unit at least once a year, but it is recommended to do this every 20 hours after intensive use of the mowers. If the first signs of malfunctions with the mechanism appear, the lubricant should be applied as soon as possible.

How to replace a trimmer gearbox: an action algorithm

To replace the gearbox with a similar part from the same manufacturer, it must first be disassembled and removed from the rod. Operate with the following algorithm:

- loosen the clamping bolts located under the transmission mechanism;

- using round nose pliers, remove two corkscrew rings;

- using a puller, the bearings are driven from the driven and driven shafts;

- then assemble the mechanism, in the reverse order installing all parts.

The disassembled gear is shown in the photo below.

Disassembled gearbox

If the puller is not at hand, then you can try carefully knock down bearings. When they become attached and do not budge at all, you can heat them with an industrial hair dryer (at a temperature of 600 ° C) and remove them.

Assembling a gear assembly is easier than disassembling it. You may need only a light tapping hammer for planting parts in place. After assembly, be sure to check that the driven shaft rotates by hand.

When there is a need to replace the transmission unit with a non-original part, then you should consider their interchangeability. This should take into account:

- rod diameter (this parameter is often 25.4 or 26 mm);

- the drive shaft parameters are the shape of the docking point and diameter (its common value is 8 mm);

- option for attaching protection.

If the considered parameters match, then it will be possible to install parts from other models.

Timely lubrication of the gearbox will ensure its continued operation without repairs. In addition, modern materials well protect the metal from corrosion, increase its wear resistance. Preference in choosing should be given to the lubricant recommended by the manufacturer of the trimmer in use. If such compositions are not available for purchase, then the considered or other suitable analogs should be used. When it is necessary to disassemble the mechanism when carrying out repairs, this should be done carefully so as not to damage individual parts.

/rating_on.png)

/rating_off.png)