Homemade fishing line for trimmer

Many users of mowers, both electric and with gasoline engines, some time after using the purchased fishing line ask themselves: what can it be replaced with? If you exclude dangerous options (a chain from a chainsaw, a blade from a hacksaw, wire, cable, string, etc.) that can inflict severe injuries to the user and others, then the best way out of the situation is homemade plastic bottle.

How to cut a bottle on tape

Before proceeding to the manufacture of homemade cord, you will need to prepare the material itself, namely plastic tape of the necessary width and length. To dissolve a PET bottle on a tape, use various devices which algorithm of production can be found on the Internet. If you are going to mow large areas of grass and you need a lot of homemade cord, thenOf course, it makes sense to make a more difficult bottle cutter from the corner or U-shaped aluminum profile. The process of making the bottle cutter is shown in this video.

But if the mass production of plastic tape does not interest you, then from time to time you can dissolve the bottle into strips in a simple way.

- Take the usual cork from PET bottles.

- Cut it in half (but not completely).

- Remove all sides inside the cork.

- After folding the cut cork in half, pierce it with a knife through, as shown in the figure below, while being careful, as the plastic is very hard. To facilitate the process, the tip of the knife can be heated.

- Cut the bottom of the plastic bottle with scissors (if possible evenly, without chipping). Insert the bottle into the fixture from the side where the knife blade is sharpened, and start slamming. When a small strip appears - just start pulling it.

Thus, the entire plastic container will bloom on the tape of the same width.

The pocket version of the bottle cutter, which you will always have on hand, can be made from the usual pencil sharpenerspreferably made of aluminum.Details on how to make it are shown in this. video.

How to make a trimmer line

The cut ribbon of PET bottles, if you wrap it on the trimmer, will mow, but not for long, because it is fragile and quickly breaks. It needs a little improvement, and for this you need to do the following.

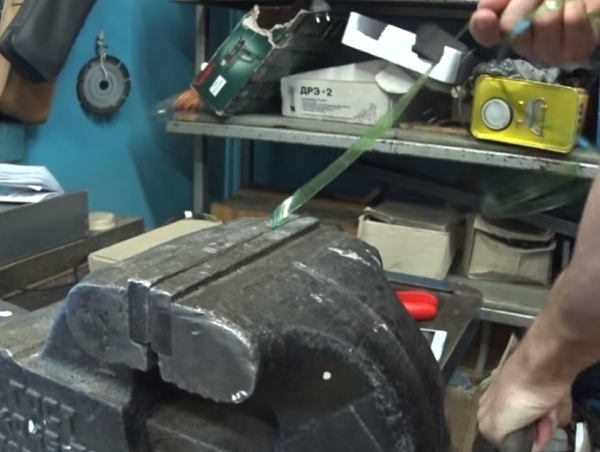

- Insert one end of the plastic tape in a vice and clamp it.

- The other end of the tape can be clamped into a drill or screwdriver. Insert it into the screwdriver cartridge so that it holds well in it and does not jump out under tension.

- Turn on the smallest revolutions on the screwdriver and start twisting the tape, be sure to keep it taut, otherwise it will start to tangle.

- After the tape stops twisting without releasing the tension, begin to warm it up. building hair dryer. Since this plastic has shrink properties (shrinks when heated), the coils will level out and solder.

- While warming up the twisted tape, from time to time turn on the screwdriver and turn the rope to align the turns on it.

- When you warm up the whole tape, you will have a self-made plastic rope that is quite plastic and strong.

- In the case when you do not have a drill at hand, you can use an ordinary plastic tape to twist stickas shown in the following image.

- Building hair dryer can be replaced by an ordinary cigarette lighterif you make a cord of small length.

As practice shows, the trimmer line, made with one's own hands from a single twisted tape, mows the grass well, but if it comes across stones or branches, then it wears out quickly. To eliminate this disadvantage, it is recommended weave a plastic rope of several tapesFor example, from two or three. The following figure shows a homemade cord woven from three plastic strips. Although it differs in thickness from a single cord, it is much stronger than the first one, and serves for a longer time.

Then, as usual, the trimmer line is inserted into the mowing head or wound onto a reel, and then inserted into the head, after which the protruding ends are cut so that they do not touch the protective casing.

Thus, literally from scrap materials, you get a free trimmer line that can be made in unlimited quantities.

/rating_off.png)