Blowing the heating system compressor

Nobody wants to live in a cold apartment or house. It is even less rational to spend money, paying for resources that are not optimally spent. Unfortunately, even the most advanced individual heating system can get clogged. For a common utility network, this phenomenon is inevitable. Cold or different temperature radiators in the rooms - the first sign that you should rent or buy a compressor to flush the heating system and carry out the appropriate procedure.

Content

Why pipes get clogged, and when flushing the heating system is needed

During operation, any heating system somehow suffers from pipe pollution. This may be a fairly small sedimentary layer, the accumulation limit of which is limited by the volume of coolant in an isolated network. But in municipal distribution pipelines, the amount of dirt can become so large that water completely stops its movement. There are several reasons for this phenomenon:

- dirty heat carrier, land ingress into the heating network during pipeline repairs;

- the accumulation of waste products of bacteria;

- the formation of a sedimentary layer of mineral salts, the concentration of which in the social structure of heating is fairly stable due to the constant addition of water to the boilers;

- the consequences of the destruction of steel pipes, the remains of the oxidized metal.

Do not think that the compressor for flushing heating will never need the owners of modern individual systems. An isolated structure, where a limited amount of coolant circulates, without adding new portions of water with mineral impurities is generally stable. However, it plays a big role fluid flow rate, the so-called volumetric pumping of the working fluid per unit of time.

Especially critical to the change in the nature of the circulation warm floor. The effective cross section of its thin tubes drops dramatically even with the appearance of a modest plaque on their walls. In addition, even a thin layer of sediments that does not significantly affect the fluid flow greatly reduces heat transfer in any system, with steel, cast iron, aluminum or bimetallic radiators. Therefore, a compressor for flushing heating can be useful not only for service companies providing relevant services, but also for individuals.

Compressor Rinsing Methods

To do everything quickly and efficiently, it is recommended to use a compressor when flushing heating radiators, piping systems to restore the heat exchanger of a gas or other heating boiler.For some procedures, specialized equipment will be needed, for others, a conventional household (for example, automotive) compressor is sufficient.

Hydraulic and hydrochemical washing

Hydraulic flushing is considered a classic of the genre. For its implementation to the inlet of the heating circuit after disconnecting the corresponding pipe from the boiler or tapping tap connect the water source. It may be communal water supply.

To the drain pipe of the heating system or a specially made inset attach a hose for draining dirty fluid into the sewer. For the procedure in the simplest case, no equipment is required. Water is supplied to the pipeline.

Important! The minimum pumping volume for cleaning the system should be no less than five times the amount of coolant.

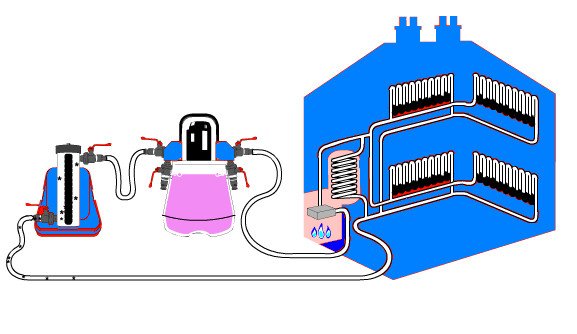

The procedure can be carried out with the addition of chemicals, in the simplest case - soda ash. In this embodiment, it is called hydrochemical. Cleaning can be carried out both manually, with preliminary preparation of a large volume of working composition and pouring it into the system, and with the use of a compressor.The most difficult option in terms of equipment used is as follows.

- A special flushing compressor creates pressure in the working solution and ensures its movement in the piping system. A circulation pump may be used instead.

- At the outlet of the drain pipe is installed filter that delays pollution.

- The circulation of the working solution is not less than an hour.

The procedure can be done with the help of the usual automotive compressor. In this case, the container is mounted; a 19 l polyethylene tank is quite suitable, in which purified water is poured. A removable sealing block with a tube equipped with a check valve is installed on its neck. Through it will be fed a chemical solution. In the bottom or walls of the tank is mounted input for the compressor. This is a fairly simple device that you can assemble yourself.

The chemical solution is poured into the tank.For his entry into the system is used tee. It is connected to the plumbing or other source of fluid, the output tube of the tank. The output from the tee will be connected to the inlet of the heating system. The procedure is as follows:

- water turns on;

- after some time, after pre-flushing, the compressor is turned on;

- chemical solution as the pressure increases enters the system.

By adjusting the performance of the compressor or performing a short start-stop, it is easy to achieve a fairly uniform supply of the active substance. Best results are achieved when using a compressor with low productivity. The completion of hydrochemical cleaning should be flushing the network of pipes with clean water to remove chemical residues.

Hydrodynamic cleaning

The hydrodynamic cleaning procedure allows to remove almost all the pollution from the heating system:

- residues of scale;

- soot;

- sediment solids;

- corrosion products;

- fats of organic origin;

- mineral plaque;

- waste products of bacteria.

The procedure is carried out with the help of specialized compressors equipped with nozzles, which eject water with high-energy pulses. The jet has a high speed and working pressure up to 200 atm.

However, using such attachments is difficult to act inside the pipelines. Therefore, hydrodynamic cleaning is mainly used for heating radiators. The services are provided by specialized companies, since for a private person the idea to buy equipment of this class is simply irrational, its price is very high.

Bubbling or hydropneumatic flushing

Hydropneumatic flushing is the most common way to restore the parameters of a heating system. It is the process of feeding into pipes. air-water mixture under considerable pressure. Its impact literally disrupts plaque, breaks rainfall and perfectly cleans both piping and radiators.

There are two ways to do this.

- The system is filled with water and left for up to 1 hour. After that, an air compressor is connected to the inlet and pressure is applied that the pipes and radiators are able to withstand. The system again sucks for half an hour. At the end, the drain pipe opens and dirty water is discharged. If necessary, repeat the procedure. The compressor can be used any, including automobile.

- The system is supplied active air-water mixture. When conducting this variant of the procedure, you need to use a special compressor. The device immediately delivers the finished mixture, allowing you to carry out the washing procedure as quickly as possible.

Hydropneumatic flushing often called purge. The procedure is carried out simply, quickly, without adding chemicals to the water, which can be immediately drained from the outlet.

Water hammer cleaning

The water supplied by a powerful impulse with a speed of up to 1200 m per second perfectly splits any deposits and dirt inside the pipelines of the heating system.This method has some danger for modern plastic pipes, non-welded joints, domestic heating boilers and boilers, thin radiators. However, water hammer is the most effective method of cleaning extremely clogged, old systems built on metal pipes and cast-iron radiators.

For the procedure will need:

- pneumogun, pressure accumulator with manometer and valve opened by pressing the handle;

- a compressor that generates a working pressure to form a pulse;

- source of fluid, plumbing can be used.

The mechanics are pretty simple. The heating system is supplied with water in a constant flow. The worker, tracking the indicator of pressure, produces air pistol starts.

Air pressure creates a hydraulic wave, impulse destroying deposits in pipes. The time it takes to clean the system of a private house - an hour or a little more. For the fastest possible cleaning, you can use a specialized compressor that adjusts to certain parameters of the water hammer and the volume of pumped liquid.

Similar installation can be equipped chemical containers for automatic addition to the cleaning fluid, it has a wide variety of protections, capable of combining hydraulic shock with hydropneumatic mechanics, creating an air-water mixture.

Chemical cleaning

Cleaning with concentrated active solution - a method that should apply caution. Aluminum and silumin parts, even when exposed to relatively safe citric acid, can be severely damaged. However, for steel pipes, radiators, heat exchangers for gas and other boilers - this is the most convenient method of cleaning.

The procedure is as follows:

- the cleared volume is filled with the concentrated solution;

- over time, for which the maximum effect of the drug is achieved, it is removed from the system;

- the procedure is repeated for maximum thorough cleaning;

- the system is washed with pure water to remove residual chemicals.

In the domestic environment used method with active movement. For this fluid is pumped. The most convenient way to use a special compressor.

However, it is not necessary to look for equipment of this type. You can do the usual car compressor.

- To do this, a container is made with two taps at the top and bottom. Ideal - plastic canister with a tightly screwed lid with a capacity of at least 5 liters.

- A compressor is connected to the upper branch, one of the heat exchanger nozzles is connected to the lower branch.

- A drain pipe is attached to the second nozzle of the heat exchanger, the end of which is placed in an open container.

The procedure looks quite simple. The canister is poured on 2/3 of the active solution. Turning on the compressor, start feeding. The chemical mixture passes through the heat exchanger and is discharged into the container. The fluid is pumped in portions for maximum impact.

After the canister is empty, compressor turn on the reverse. This provides a vacuum, is the reverse of the active composition. The chemical mixture flows back into the canister. During the entire procedure, care must be taken that the end of the drain tube is in a liquid. Complete the cleaning process by thoroughly washing the heat exchanger.

The following results bring good results. types of active chemistry:

- alkalis;

- organic and inorganic acids;

- solvents.

In order to wash not a separate radiator, but the system as a whole, they are used specialized tools. Their solution is pumped into pipelines and left for a period of 6 to 10 hours to completely dissolve the contaminants.

Selection of compressor for flushing

Today, the retail market is represented by a huge number of models of equipment for various types of washing. It is practically impossible to formulate specific requirements for the compressor, since it is selected on the basis of future operating conditions. This includes the volume of pumping, the ability to work in a particular mode, the ability to raise water to a height, and much more. However, there are brands that have earned a good reputation and offer devices with an attractive price and technical, functional indicators.

Ropulse

Compressors of this brand are distinguished by a sufficiently high versatility, suitable for servicing pipes, individual radiators, heat exchangers. In models the disinfection circuit of the pumped liquid is present, which allows for the purification of drinking water pipelines with their help. Compressors Ropuls show good performance in the procedures of maintenance of systems "warm floor" and even solar collectors.

Rokal

Compressors of this brand provide gentle cleaning. The devices are of the manual type, weigh a little, are compact, and in the operating mode they create a pressure of 1 atm. Their small capacity (on average - 40 l per minute) allows for procedures with a minimum consumption of the active compound.

Cillit-boy

Compressors of this brand are able to solve almost any task. They are suitable for maintenance of systems made of steel and plastic pipes, show good results when cleaning a warm floor. In the functionality of compressors disinfection is includedthat allows them to be used for flushing the network of drinking water.

The advantages of compressors include the ability to carry out hydropneumatic cleaning with a very uniform supply of air-water mixture for the most effective action.In addition, the devices are capable of operating in a water hammer mode.

The control of compressors is electronic, with convenient mechanics of setting and control of operating parameters.

Conclusion

Cleaning the heating system using compressors is not a task that should be postponed. The maintenance procedure can be carried out even with a simple automobile supercharger. At the end of it, the heating in the house will work at its maximum parameters, not only providing comfort, but also helping to save money.

/rating_off.png)