Devices for aeration of water

Aeration of water implies its purification due to oxygenation. Oxygen oxidizes various heavy metals in the water, including iron and manganese, and hydrogen sulfide and radon binds and removes harmful gases. After aeration, the water, being purified from harmful impurities, acquires nice taste and color. For the oxygen purification of groundwater, special devices are used - aeration compressors.

Content

Varieties of devices for aeration of water

There are a number of methods for purifying water, including aeration. The method in question is different from other techniques. simplicity, availability and efficiency of water treatment. As the advantages of the method by experts are noted:

- safety for the environment and human health;

- low cost of purification of well water from impurities in comparison with other methods;

- due to oxygenation, the taste of water becomes better;

- is possible automation of the process of water purification.

In turn, aeration can be carried out in 3 different ways:

- pressure system;

- free-flow option;

- ejector method.

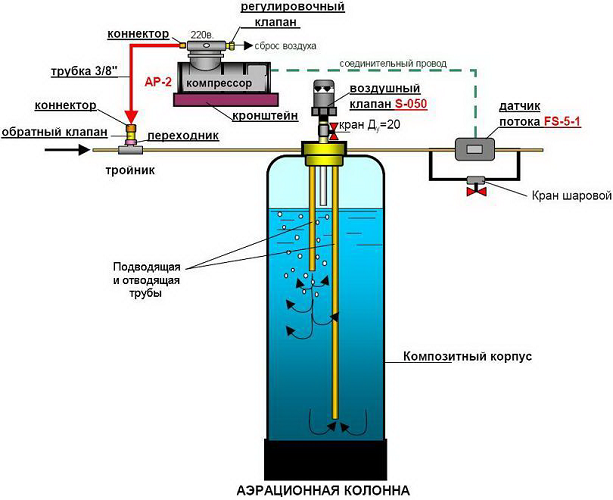

Aeration under pressure

To start the process of enriching water with oxygen is used aeration column with compressor. Components of the equipment are

- tank with a volume of 100-500 liters;

- compressor;

- filter element;

- pressure monitoring sensor;

- safety valve.

The unit is connected to a well, well or water supply, where the cleaning fluid is delivered by the pump. When the system's tank is completely filled, the compressor is turned on, activating the process of water saturation with air, due to which the oxidation of impurities occurs. The air flow is injected to a certain pressure, after which the liquid is passed through a filter, on which precipitates of heavy metal salts are deposited. At the outlet of the tank, water obtained is purified from chemical impurities.

The method is highly effective, but the equipment used for domestic use is quite expensive.

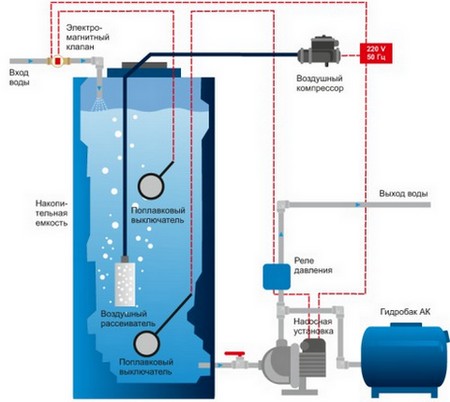

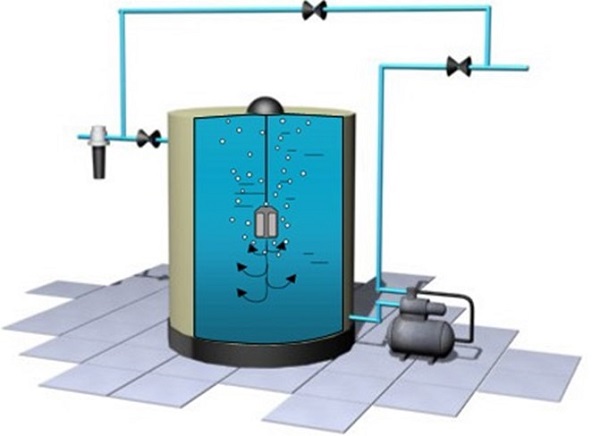

Free-flow technique

When free-flow system fluid in the tank for aeration flows through the nozzlesthat promotes rapid contact with air. A working air compressor supplies air, and oxidized impurities are deposited in the filters at the bottom of the tank. The purified liquid is sprayed out through the nozzles. For more bandwidth, an additional pump is used. The non-pressure method is used in industrial water purification systems.

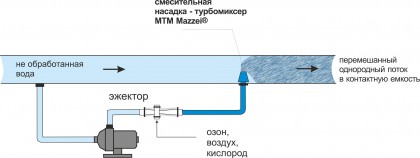

Ejector cleaning

Most common household aeration method well water. The equipment used is compact in size, available for purchase. The purification plant functions due to internal pressure and does not require power supply. The ejector forms a low pressure area in the pipe into which air is sucked through a special opening. A non-return valve closes the water outlet. The liquid, mixed with air masses, passes through the filter, where oxidized impurities settle.

The principle of operation of the compressor for water

The compressor is called the device for compression and movement of gases under pressure. Devices are used in many branches of economic activity, including for domestic needs. For example, lovers of breeding fish in an aquarium or in a pond can not do without a compressor for water of appropriate capacity. The device is used to purify water from harmful impurities and saturate the liquid with oxygen.

The key phases of the operation of the water aeration device reflect the schematic drawing:

Inside the device is an electric motor, cooled by fans. A capacitor is used to start the motor. The motor rotates the shaft, by means of an eccentric mechanism, the rotation is converted into a translational motion of the piston, which compresses the air entering the chamber. A special valve system regulates the discharge and transportation of compressed air.

Compressor Model Overview

The compressor is selected for specific conditions of use. We give a brief overview of popular models for aeration.

Air pump 2 - American-made compressor.Over the past 10 years it has been recognized as a high-quality and reliable device for aeration cleaning of liquids. The unit is used in systems pressure aeration for purposeful oxygen supply to water pipes, tanks for the purpose of oxidizing dissolved impurities and removing volatile gases. The device has a good level of performance (420 liters / hour). From a budget point of view, this device is expensive: 22000-26000 rubles.

AS-19 - a sample of Chinese production. Popular when used in pressure aeration systems as budget alternative American-made devices. Capacity up to 40 liters / hour. It is inferior to American devices, not only in terms of performance, but also the duration of work. The price of the model is about 10,000 rubles.

/rating_off.png)