Which borehole pump is best to choose

Almost every owner of private housing construction raises the question of choosing a water pump for a well. That it is the main component of the water supply system. Only the correctly selected model of the unit, taking into account the characteristics of the well, will not cause any problems and inconveniences in its use.

Content

Well Characterization

To choose the right pump for a well, you need to know its exact characteristics. Typically, the organization conducting drilling with the use of professional equipment, upon completion of the work provides an act, which lists all the parameters of the well.But if the drilling was not done by professionals, or the documentation was lost, then you will need to independently determine the characteristics of the source of water intake.

The main characteristics of the aquifer well include:

- static and dynamic water levels;

- flow rate facilities;

- pipe diameter;

- depth of the bottom of the bottom.

Static level

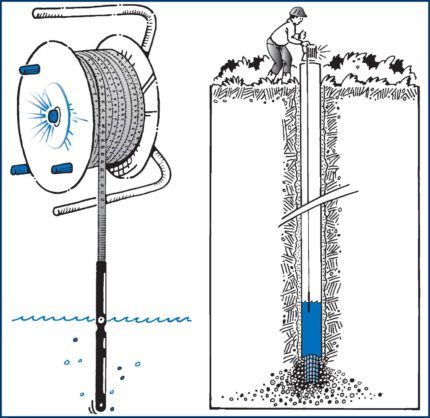

By static fluid level in the well means distance from the ground to the water mirror.

To find out this distance, you must do the following.

- Approximately one hour before the measurements, stop the water intake from the well to restore its natural level.

- Take a string of sufficient length and tie a small load to its end.

- Lower the rope into the hole until you hear a sound like a clap. The sound will indicate that the weight has reached the water.

- Next, make a mark on the string and pull it out.

- Lay the rope on the ground and measure the distance from the end of the weight to the mark using a tape measure. The result will be the value of the static water level.

Dynamic level

This parameter is measured after the unit has been in operation for a while and determines distance from the water mirror to the ground surface. Measurements are carried out as follows.

- Turn on the well pump and let it run for a few minutes. If you do not have this equipment, you will have to borrow it for measurements.

- Tie a plastic bottle to the end of the rope with a little water. The bottle should serve as a float and not to sink.

- Lower the bottle into the well (possible with the hydraulic machine running) and observe the rope. When the water in the mine ceases to decrease and stops at the same level, make a mark on the string and pull it out.

- Measure the distance to the mark. The result shows how much water goes down while the pump is running. That is, you will know its dynamic level.

Comparing the values of the dynamic and static levels, you can get an idea of the performance of the well: the smaller the interval between these levels, the faster the replenishment of the water column in the mine. With a small interval between levels, you can use more powerful equipment than what was used for calculations.

Bottom level

In addition, you need to find out at what distance from the static water level is the bottom of the mine. In this case, the load is lowered to the very bottom, a mark is made on the rope and the difference between the dynamic level (previously obtained) and the bottom level is calculated.

This information will help you choose the power and size of the pump, since the unit must be below the dynamic level and at a certain distance from the bottom.. For example, measurements have shown that water when the apparatus is lowered by 2 meters. And to the bottom of this mark is 1 meter. But since the unit must be slightly below the dynamic level, it will be very close to the bottom of the well and will be suck up the sand with water. If this happens, the device will fail or will supply upward turbid water.

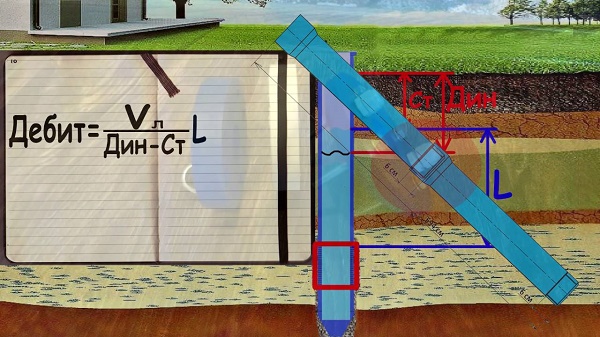

Well flow rate

The amount of fluid that can be obtained for a certain unit of time is called well flow. Measure it in m3/ h or l / min If during operation of the pump water has time to arrive in the well and does not end, then for a given source of power this hydraulic machine is enough. But if you notice that the water flow is greater than its replenishment, then for the correct choice of the power of the unit should be calculated well productivity.

- Prepare one or more large containers with a known volume.

- Turn on the pump and direct the water into the prepared containers.

- When you hear a “sobbing” sound from the well, turn off the unit. This sound means that the machine has pumped water from the mine. From this point on, note the time.

- After some time, measure the static water level. If the level has not recovered, wait a little more (without stopping the stopwatch).

- After restoring the static level, stop the time. Dividing the volume of water in the tanks at a time, you will know the debit of the well.

Knowing the flow rate, it is easy to choose pumping equipment that will match its performance.

Pipe diameter

The diameter of the casing, in fact, is borehole diameter. When choosing submersible equipment, this parameter must be taken into account so that the unit can move freely up and down the pipe.

Select pump type

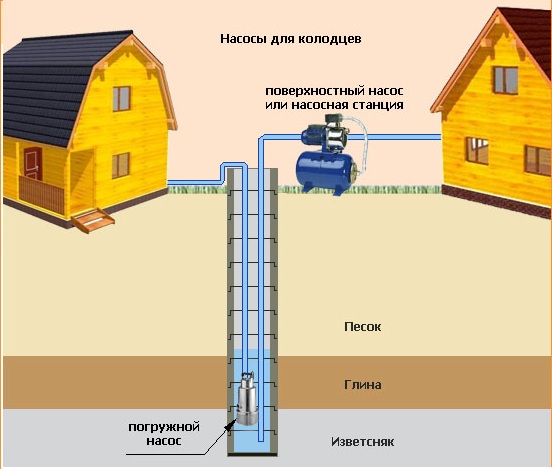

All hydraulic machines used in everyday life for pumping water from wells and wells are divided into 2 types: submersible and surface.

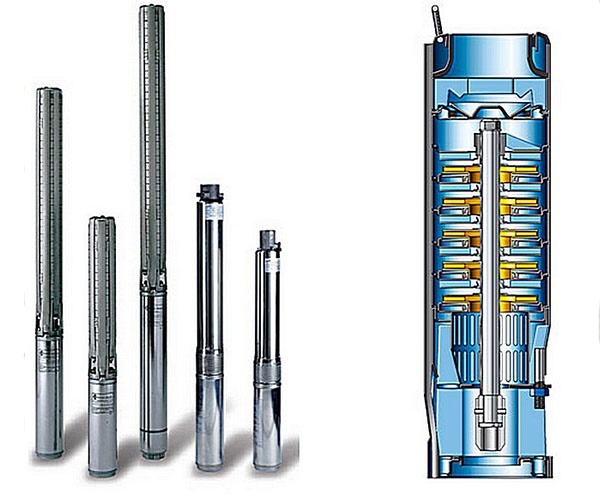

Submersible

The units are working, being directly in the water. They are designed so that the liquid is pushed out of them through the exhaust slug attached to the nozzle at the top of the pump.

Depth units (submersible) can pump out water even from artesian wells, the depth of which can be from 30 meters or more. Also, this type of pump can create a pressure of 100 meters and more due to the fact that water is pushed out of the unit under pressure.

There are also submersible well pumps, which are a combination of a downhole apparatus and a hydroaccumulator. The latter is a water tank, equipped with a rubber membrane with high elasticity. The following photo shows the pump “Aquarius” with a water tank.

As mentioned above, submersible pumping stations have accumulators. Their main purpose is to maintain the pressure in the water supply system at the required level, even when the hydraulic machine is turned off.

Pluses of submersible units:

- long service life (with the exception of vibration type pumps);

- the ability to lift water from deep wells;

- silent operation;

- the unit does not overheat, because its cooling is due to the fluid in which it operates.

Disadvantages:

- high cost (with the exception of vibration apparatus);

- due to the location of the device deep in the well, it is difficult to carry out its maintenance;

- there is a risk of “losing” the unit when the walls of the well collapse.

Surface

The work of surface stations is built on the principle suction fluid from the well through a long shlag. The unit itself is placed on the surface, and the hose connected to it is lowered into the well.

Pump stations for giving can be pretty compact. They are easy to carry by a special pen and connect (for watering plants) to open ponds, wells, and various water tanks. But there are stationary units. They are installed (necessarily with automation) in the basement of a house or in another room and serve to supply water to the water supply system.

Surface type pumps can pump from a well (Abyssinian) from a depth of not more than 8 meters. They are not able to lift water from a greater depth.

The surface type of pumps has the following advantages:

- affordable maintenance;

- small sizes;

- affordable price;

- easy installation

Minuses:

- can be used only for the well, since the suction height of the pump is 8 meters, and to raise the liquid from a greater depth, you will need to connect a jet pump (ejector) to the water intake system;

- sensitivity to the purity of the pumped water;

- high enough noise at work;

- due to insufficient cooling, the engine may overheat.

From the above, we can conclude that surface water machines are suitable for water supply from shallow wells (up to 8 meters), but if there is a well whose dynamic level is more than 8 meters, then it is wiser to choose a submersible pump.

Types of submersible pumps

Submersible devices are very popular due to the wide possibilities of their use. But not everyone knows that borehole pumps are both vibratory and centrifugal.

Vibrating

Vibration-type water pumps are the most common among summer residents. Devices have low cost and differ simplicity of design. Vibrating pump consists of a chamber with a membrane, as well as intake and exhaust valves. The device works according to the following principle:

- an electromagnet with a frequency of 50 Hz attracts and releases the membrane;

- the membrane, in turn, moving downwards, creates a vacuum in the chamber, and when it moves upward, an overpressure;

- under vacuum, the inlet valve opens and water fills the chamber;

- after an overpressure occurs, the exhaust valve opens and water is pushed out of the unit.

Due to the fact that the valves open (close) 50 times per second, they wear out quickly along with the rest of the machinery. But the main drawback of this type of pump can be called strong vibration the whole body. Vibration can lift fine sand from the bottom of the well and block the filter of the apparatus. In addition, the detrimental effect of vibration affects the walls of the well, contributing to their destruction.

Centrifugal

A submersible centrifugal pump works on the same principle as a surface unit of this type. The main organs of the apparatus are the electric motor and the impeller having blades. When the latter rotates at high speeds due to centrifugal forces, water is pressed against the inner walls of the casing of the unit and is pushed out of it. At the same time, a vacuum occurs in the area of the inlet of the apparatus, which promotes the suction of fluid into the hydraulic machine.

Thanks to this design and the absence of vibration during operation of the equipment, centrifugal submersible units are characterized by high performance, reliability and do not destroy the well.

What type of units is better

The only advantage of a submersible vibration pump over a centrifugal pump is the price. Vibrating devices have a cost several times lower than that of similar equipment with an impeller. But you should know that the vibration pump can be considered a disposable consumable: if it breaks down, the device changes to a new one, as it is beyond repair.

In addition, the vibration apparatus is not recommended for the supply of drinking water. This is due to the presence in the water of small particles of soil, raised from the bottom of the well by vibration produced by the unit.

Therefore, if it is intended to use the pump only seasonally, for example, for watering plants in the country, then an inexpensive vibration apparatus will do. But if it is required to carry out a water supply system in the house, and connect it to the well, then it is better to immediately install a reliable and durable unit. In this case, the best pump for the well is a centrifugal submersible.

Overview of well pump manufacturers

The presence of a large range of pumping equipment complicates the process of choosing the right machine. This is explained by the fact that for many units the technical characteristics are in many respects similar. Therefore, when choosing a device, you need to pay attention not only to its performance indicators. You should check the quality of the equipment assembly, find out about the warranty period for it, and, of course, pay attention to the cost of the hydraulic machine. The following is a rating of popular manufacturers, compiled from reviews of owners of pumping equipment.

CALIBER

This trademark has been represented in Russia since 2001. Under the brand "Caliber" for sale a huge number of types of power tools and equipment, including pumping. All production facilities that produce products for this company are located in China. Therefore, hydraulic machines “Caliber” are popular because low price on them.

For example, submersible device Caliber NPTSS-1.5 / 50-550 has a low cost (about 4,000 rubles) and a fairly good performance - 25 l / min. Also, the device has a power of 550 W and is able to create pressure in the system up to 5 atmospheres.According to the design of the CALIBER NPCS-1.5 / 50-550, this is a vortex pump. That is, the main element of the apparatus is an impeller, slightly different in shape from the same element in centrifugal units.

But, despite its popularity and good technical characteristics, the devices of the “Caliber” brand have short service life - about 2 years.

Herz

Homeland brand "HERZ" is Germany. Under this brand there is a very large range of products, including high-quality pumping equipment that can run smoothly for many years.

An example of a sufficiently reliable unit can serve borehole pump HERZ 100HQ JD. This is a submersible type model, and it is designed for pumping clean water (100 g of sand per 1 m3 water). This means that this unit cannot be used in “impure” wells, since it will simply fail. But, if you follow the rules of operation, the equipment will work for about 10 years.

The device has a low power of 550 W, but good enough performance - 3 m3/ h In addition, the hydraulic machine can create a water pressure of 50 meters. Therefore, if your well has good clean performance, then it will not be a pity to spend 7,500 rubles for these units.

Aquarius

Pumps of this brand are produced in Ukraine, in the city of Kharkov. The brand “Aquarius” belongs to the company “Promelektro”, which produces fairly high-quality units that can operate for 10 years without a single failure.

For home use often buy the device Aquarius BTsPE 0.5-16U. This is a 400 W deep unit with a capacity of 3.6 m3/ h and a pressure of 27 m. The device can work smoothly in water with sand impurities of not more than 50 g / m3.

The height of the water rise in Aquarius BTsPE 0.5-16U 16 meters.

When installing the equipment, it should be taken into account that the pump should be at least 1 meter above the pump immersed in the liquid. You also can not install the unit if the distance from its bottom to the bottom of the well is less than 40 cm.

This unit is designed for continuous operation without overheating. You can buy it for about 5,000 rubles.

JLEX WATER

Is a product of domestic production. The brand "Vodomet" is the property of the Russian company "Dzhileks", creating a fairly high-quality pumps, some of which are capable work in wells with a high level of “dustiness”"(2 kg of sand per 1m3 fluid).

For domestic use, the device is well suited WATER MOTOR PROF 55/50 Ahaving a power of 600 watts, performance 3.3 m3/ h and water pressure 50 m.

The device is designed for water with particles up to 1.5 mm. The device can be immersed to a depth of 30 meters. The cost of the pump is around 8,000 rubles.

Belamos

It is a company from the Republic of Belarus, which for many years has been engaged in the production of pumping equipment, both for industrial and household purposes. Especially in high demand are Belamos submersible-type devices capable of raise water from great depths.

For example, the pump Belamos 3TF-60/4 has a capacity of 900 watts and can raise the water to a height of 60 meters. The performance of the unit is also at a good level. He is able to pump 4 m3 fluid for 1 hour.

The device can operate in water with a mechanical impurity content of not more than 150 g per 1 m.3 water.

The documentation for the device says that it is designed for 10 years of service, subject to all rules of operation. It is possible to buy the unit for approximately 10 thousand rubles.

GRUNDFOS

This is a Danish company that has offices in almost all countries of the world. The company specializes in the manufacture of pumping equipment, and its volume of production is 16 million units per year.

Choosing a durable and reliable device of this brand, you can pay attention to the model. GRUNDFOS SQ 2/70having a permanent magnet motor. Hydraulic machine has a power of 1150 W, maximum performance of 3 m3/ h and a maximum pressure of 89 m.

Since the brand GRUNDFOS is very famous in the world, this unit can be purchased at a price of about 43,000 rubles.

Wilo

This German company has been operating in the Russian market since 1997. Its products - pumping equipment - are notable for their reliability, perfect design and unsurpassed German quality.

It is no secret that if it is necessary to raise water from a very deep well, then an ordinary submersible pump will not be suitable for this task. You will need to use special equipment, namely artesian pump. The aggregate is best suited for this purpose. WILO SUB TWU 4able to lift liquid from a depth of 200 m.

The device has a power of 1.5 kW, a pressure of 120 m and a capacity of 6 m3/ hYou can buy a pump for 24,000 rubles.

/rating_off.png)