Basic information about centrifugal pumps

When the task of organizing water supply or pumping a variety of liquid media and colloids is set, a centrifugal pump is often the tool to solve it. This device is quite simple, reliable, with clear mechanics of work. On the modern market there are a variety of models of equipment of this class, among which you can choose the option that perfectly matches the needs of the future owner.

Content

Scope of application

Due to its versatility in the characteristics of the pumped liquid, centrifugal pumps have found a huge list of application options. They are used in the oil and gas industry, installed in domestic water supply networks, work at gas stations.

No centrifugal pumps, compact and reliable, can do without fire fighting aircraftdrawing water in open water. Installations of this class use city fire services. List all the applications of devices with a centrifugal supercharger is simply unrealistic.

Device centrifugal pump

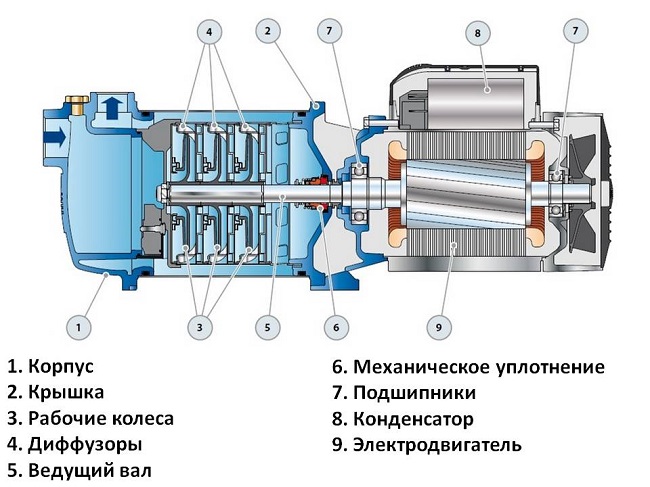

The centrifugal pump, the optimal purpose of which is to create a constant flow of fluid without its reverse movement - a device popular with consumers. Its design consists of several large functional blocks.

- Drive unitwhose role is to create torque. As a power unit for solving this problem can be an electric motor (powered by alternating single-phase, three-phase voltage, direct current), internal combustion engine (gasoline or diesel).

- Power shafttransferring the moment to the working body.

- Turbine wheelequipped with tilted blades, which is the main working body.

- Protective casewhich can perform the functions of a power element for fastening all parts of a structure.

The equipment of the centrifugal pump also includes bearings, providing smooth rotation, reducing friction losses, improving reliability, and a variety of sealing devices. The nature of the latter may vary depending on the type of fluid for which the installation was created.

In addition, centrifugal pumps can be equipped with secondary flow conversion systems. This is done to stabilize the output pressure or to ensure that the fluid rises to the desired height for the consumer.

Principle of operation

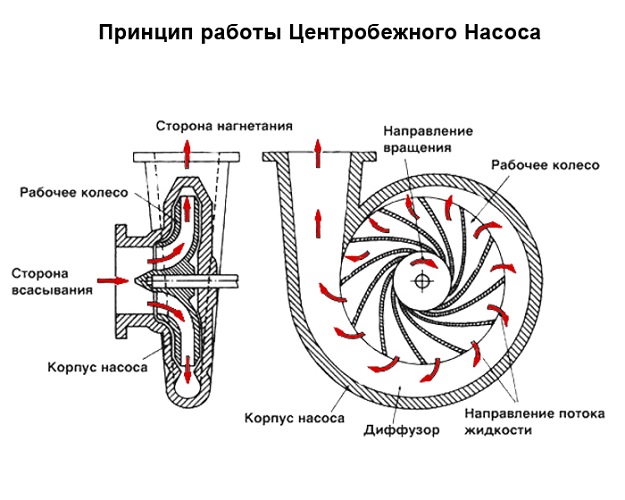

The principle of operation of a centrifugal pump is the intake of water as a result of a decrease in pressure in the inlet nozzle and the release of liquid with a pressure from the outlet nozzle. This is due to the physical phenomenon of centrifugal force. To understand how everything works, you need to step by step illustrate the principle of the installation and the ongoing processes.

- When starting the drive starts rotation of the working body - turbine wheels with inclined blades.

- The inlet pipe supplies water to the zone of the turbine axis.

- Grabbing the blades, the liquid begins a circular motion with them.

- Thanks slope of the blades fast water is drained to the edge of the circular area of the work area. This occurs both under the action of centrifugal force of rotation, and due to force mechanics, due to the angle of inclination of the blade.

- When fluid moves from the sampling point, pressure dropthat causes the natural abstraction of water from the inlet pipe.

- Finishing its movement on the edge of the circular zone of the turbine wheel, the water moves with great speed, creates considerable pressure and is naturally ejected through the outlet nozzle.

This process physics allows us to explain why a centrifugal pump can not only pump water from the surface, but also lift it out of the wells. At certain ratios of wheel dimensions, its revolutions, drive power, such high rates of suction force are achieved that the liquid easily rises from a depth of several meters.

Additional design elements

If the above functional diagram contains a small number of significant nodes, the actual device of the centrifugal pump includes additional structural elements:

- transmission pipeline, through which the liquid flows to the point of collection;

- coarse filters, solving the problem of preventing the presence of mechanical suspensions in the turbine chamber;

- valve systemsblocking abnormal reverse fluid flow;

- pressure metercontrolling the performance inside the working chamber;

- pressure gauge to control the output stream entering the water supply system.

The equipment of any domestic and especially industrial centrifugal pump includes valves. It can be manual or automatic. The task of the nodes of this class, without which more than one drawing of the fluid supply system cannot do - not only protect the pump from abnormal and emergency situations, but also, if necessary, control the input and output flows of the pumped body. It is easy to illustrate the importance of the operation of valves in the case of metering devices. Centrifugal pumps of this type operate as follows:

- the signal from the control device initiates the start;

- mounted on the outlet nozzle sensor considers the pumped volume;

- when a certain threshold is reached, the counter signal goes to electronically controlled discharge valvewhich blocks the flow;

- the growth of the outlet pressure is monitored by the sensor, which stops the engine when it reaches a certain value of the parameter.

The gate of ProFactor is locking and adjusting

Classification of centrifugal pumps

Before considering the accepted classifications according to which devices are segmented on the market for the end user, it is necessary to decide on terminology. Centrifugal systems are dynamic machines, one of the subclasses of pumps. They affect the transported body as a primary mechanical force, and the resulting secondary physical processes. By this, centrifugal systems differ from membrane, vibration, and other types of installations.

Pumps on the market today come in several categories and subspecies. This is done both in order to improve and indicate the level of functional suitability of the device, and its compliance with certain operating conditions.

According to the design of nodes

According to this criterion, the pumps are divided into:

- single-stage and multistage by the number of impellers;

- by the number of output streams;

- one-sided arrangement of the inlet and two-sided, with the design can implement both the principle of ease of connection, and to ensure the intake of increased volumes of water without increasing the diameter of the supply hoses;

- with a spiral, directional, annular flow outlet, which form the impellers;

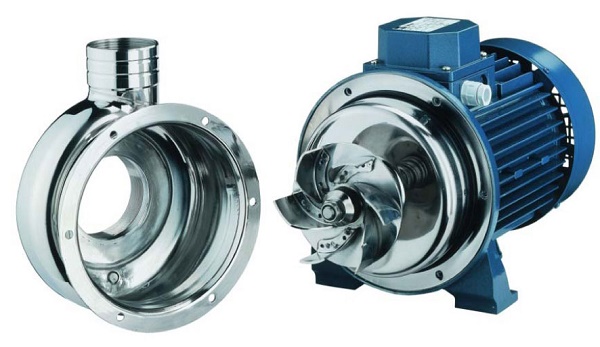

- with open and closed turbine wheel.

Centrifugal pump with open impeller

By location method

Types of centrifugal pumps are divided by the design. Surface able to lift water from a deep well or open source, are performed in buildings without sealing. In the same time submersible can not boast of suction power, however, create a significant output pressure to supply fluid to the height, performed in a sealed enclosure.

Surface Centrifugal Pump Elpumps JPP1300F

By type of pumped media

There is a classification according to the type of pumped liquid. Here are centrifugal water familiar to the average user.pumps with minimal protection measures, as well as installations for the transport of flammable liquids, oils, colloids, environments with mechanical impurities. All types of devices for this classification have differences in the design of the turbine, sealing systems, isolation from the external environment, spark protection and much more.

Other varieties

Horizontal and vertical pump show varying degrees of suitability for solutions with critical performance requirements. This is due to the nature of the fluid intake and other features of the installations. In particular, vertical centrifugal units are less effective as hydraulic machines, however, they can be more convenient in terms of installation inside various structures.

Vertical centrifugal pump

Other divisions of pumps on the market describe some features of the applied engineering solutions.

- Cantilever pump it is assembled on a solid metal frame, which allows to avoid the mutual displacement of the functional units, to reduce or neutralize the axial loads of the engine and the turbine.

The pump 2K-6, 2 K-6 console centrifugal for water

- Monoblock option The installation implements the principle of reducing the number of moving parts and friction losses by directly connecting the axes of the engine and the impeller.

Pump monoblock centrifugal SPERONI CXM 60 / 0,37

There are also other classification divisions, interesting first of all to experts, who are faced with the goal to choose the best variant of the device for solving the problem with a rigid, precise framework of conditions, requirements and restrictions.

Recommendations for the installation of centrifugal pumps

Correct installation of a centrifugal pump is a prerequisite for its stable operation, durability, and compliance with service periods declared by the manufacturer. But attentiveness and adherence to norms not only provides. Installed in accordance with the recommendations of the manufacturer and the requirements of industry standards, the unit will eliminate such undesirable phenomena as excessive noise, vibrations and the associated deterioration of connection parameters, wear, and also eliminate the occurrence of various abnormal and emergency modes of operation.

Centrifugal pumps are installed in accordance with their parameters according to the following rules.

- The axis of the engine and turbine unit must placed horizontallyif the opposite is not stated by the manufacturer and is not caused by the design features of the pump.

- For installations with direct connection to the pipeline rupture, with a capacity of up to 1 kW, installation with mounting on the wall, floor surface or other supporting structure is allowed.

- Pumps up to 10kW Mandatory mounted on a metal support frame, fixed on the surface of the ground, floor, power structure. It is allowed to install damping rubber gaskets between the points of support and the corresponding construction sites of the centrifugal unit.

- Devices with power over 10kW Must be installed on the frame, attached to the concrete cushion-foundation. The dimensions of the latter should exceed the size of the body or console of the pump by 100 mm in all directions.

- When installing the pump from the extreme point of the motor unit to the nearest wall or element of the fence should be at least half a meter.

- Thermal insulation of the drive unit, the engine, is not allowed if this is not declared by the manufacturer’s instructions for specific operating conditions.

Important! Before you connect the pump to the piping system, you must manually verify the operation of the device by disconnecting it from the power supply: turn the shaft and the turbine without a protective casing. Also, all underwater and discharge hoses and pipes should be flushed.

Installation and connection of the pipeline network must also obey certain rules.

- The inlet and outlet connections must be suitable for the respective connection points freely, so that at the end of the installation there is no effort on the pump structure.

- When the ends of the pipeline flanges must be parallel, for their placement it is not permissible to put considerable efforts, when connecting between the surfaces of the contact elements, gaskets are installed (their character depends on the type of working fluid).

- The installation of a centrifugal supercharger should be carried out so that the desired direction of fluid transfer corresponded to the arrow on the device.

- At the outlet of the pump must be mounted pressure gauge.

- Mechanical filter inlet installationif its installation does not contradict the nature of use of the pump, it is obligatory.

- Inlet and outlet connections are equipped with shutoff valves.

- To ensure the possibility of draining the system, after the outlet, at the lowest point of the pipeline network, stop valves are installed with a drain for drainage.

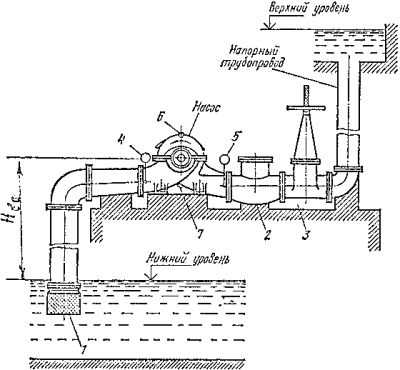

A separate set of rules applies to complex structures, piping systems with several pumps installed. The simplest of them relates to the installation of two blowers at one point, in parallel, to create an intense fluid flow. In this case, each of the pumps is equipped with a check valve at the outlet.

Installation diagram of a centrifugal pump

The average consumer who buys a centrifugal device for domestic use can be given a couple of tips. When installing you need exactly follow equipment manufacturer instructions. If it is recommended to install the pump on a flat horizontal surface, you should not think that it is only the position of the axles, and the unit can be fixed on the wall. This can disrupt the operation of safety devices, cause increased wear of components, and reduce the operating performance of the installation.

Main characteristics of centrifugal pumps

In order to choose the right pump for supplying water to a private house from a well or solving a different task, it is necessary to consider not only the figures given in the documentation for the device. However, for general acquaintance with the parameters that are useful for the correct formulation of the problem, it is reasonable to give the characteristics of devices for pumping fluid.

- Performance or feed. This figure describes the amount of fluid that the pump discharges from the outlet in the event that the engine develops its rated power.

- Head pressure - the difference in pressure between the inlet and outlet.

- Pressure characteristics centrifugal pump - this graph shows the relationship between pressure and plant capacity, allows you to empirically analyze the sufficiency of supply on individual floors.

- Suction lift indicates the depth at which the pump can take water.

- Nominal pressure - the rate at which the pump in the water supply network can operate continuously.

There are a number of parameters that are useful for professional analysis and design of a water supply network, for example, a private house. In practice, simplified techniques are often used. The approximate scheme of pump selection looks like this.

- The average is done consumption calculation. To do this, the existing devices for water extraction are analyzed, their indicators are summed up. In two or more storey houses, the total consumption figure is determined, and the amounts of water necessary to ensure the comfort of each floor are allocated.

- Determined by nature of the water intake zone. For the well, the depth is taken into account, the installation location of the pump is analyzed (height from the ground).

- Are fixed water supply network height parameters. This is done for two or more storey houses.

According to these parameters, with sufficient accuracy, you can select the appropriate pump. The nature of the fence location will tell you what kind of suction lift indicator the device should have. According to the number of floors (height of the rise of the fluid), the calculation and selection of the model is made according to the pressure characteristic.

The most important part of the analysis is the pressure-flow characteristic, it will show whether the pump is able to provide water supply in volumes of comfortable use to the floors above the first one. The procedure is as follows:

- for the floor is calculated pressure drop (rise footage);

- the graph is a point corresponding to the reduced indicator;

- determined by the amount of filing on schedule.

If the resulting figure is more than the required volume for a particular floor - the pump will cope with the task. Otherwise, you need a more productive or powerful device.

But even with careful consideration of all the features of the water take-off point and the distribution network, there are mistakes. Their reason - lack of accounting hydraulic resistance of the pipeline structure, dependences of indicators of selection and pressure, analysis of relevant characteristics of pumps. But this is a design level inaccessible to average users.

Common centrifugal pump failures and methods for eliminating them.

The centrifugal pump is quite simple equipment.Some of the faults will require the intervention of specialists who will carry out the necessary repairs. But a certain list of abnormal modes of operation or problems can be resolved on your own.

- At decrease in pressure check the inlet. If coarse filters are installed on it - carry out maintenance. It will not be superfluous to remove plaque on the walls of the pipeline of the incoming circuit.

- The reduction in pressure is eliminated on pumps equipped with engine speed regulator. The control pressure gauge determines the fluid pressure at the outlet, if it does not correspond to the nominal pressure, the rotational speed of the drive increases.

- Increased noise, shaft beating, vibration directly indicates the need to replace seals or maintenance of bearings. It may also indicate loosening of connections on the case. Before tightening, be sure to turn off the device and allow the engine to cool.

- The appearance of leaks, the flow of fluid from taps under high pressure indicates that the pump has exceeded system requirements. Reduction of supply is made by installing control valves at the inlet or accumulator with a sensor at the outlet.

- Water cut off most often associated with the ingress of air into the system. This may indicate both the absence of liquid at the inlet and the excess of the nominal height of cavitation. In this case, it is necessary to carefully check the condition of the water source.

- Excessive heat - A signal that it is time to carry out prevention. Inspect bearings, check gland tightening, replace grease, clean contact and terminal elements.

Immediately it should be noted: with careful, attentive installation of centrifugal pumps in accordance with the general rules and recommendations of the manufacturer, it is extremely rare to disturb the owners of such units.

However, no one is immune from surprises. Therefore, it is reasonable to conduct periodic inspections of equipment and prevention.

/rating_off.png)