How to choose an abrasive for sandblasting equipment

The task of quick and high-quality cleaning of the surface of an arbitrary material is of great importance in various fields of activity. For example, it is extremely necessary in auto repair shops engaged in painting cars: after preliminary body preparation, paint adheres better, it lasts longer. It is also impossible not to mention the need to clean metal workpieces from traces of corrosion in industry, removal of scale and slags from welds and much more. In order to carry out works with high productivity and at the same time achieve acceptable economic efficiency, it is necessary to choose the right abrasive for sandblasting.

Content

What is sandblasting

The sandblasting technique was patented in 1870 by the American inventor Benjamin Tilman. If you describe the technology in simple terms, you can imagine the process of surface treatment as follows:

- selects an abrasive powder, specially created or suitable for solving one or another task;

- a pneumatic compressor acts as an energy source;

- sand, flying out at a tremendous speed from a nozzle of a special design together with air, with a force hits the treated surface.

As a result of such exposure from metal, wood, plastic any pollution and coverings are removed.

Simple and common materials offer the highest economic efficiency of use and achieved results of processing. In particular, it can be successfully used to sandblast the usual sifted river sand. In this case, it is possible to choose, so to speak, the characteristics of the working fluid (for example, particle size) in order to obtain the desired speed of operation and the final surface parameters.

However, if you take sand for sandblasting machine, you should understand that this material has both advantages and disadvantages. The latter are so weighty that processing with such an abrasive is prohibited in some countries at the legislative level.

Features of the use of quartz sand

Sand for sandblasting equipment in industrial surface treatment or work in a small workshop can be of different types. Apply to:

- river, sedimentary type with high fractional uniformity;

- river, alluvial type with a fairly high variation in the size of sand grains;

- quarry mining;

- quartz natural origin;

- quartz industrial manufacturing.

Types of sand in the list can be considered as a listing in terms of abrasive functionality. River alluvial - the weakest. With its help, carry out the final work or fine cleaning of surfaces.Quartz industrial origin has in its composition up to 90% of solid mineral compounds. This abrasive is expensive because it is obtained by the method of filtration, sifting with the separation of only certain fractions of natural sand.

Complete hardness table completely artificial material. Quartz sand, obtained by crushing crystals, is distinguished by high hardness, enhanced cleaning ability due to the pronounced shape of particles with many sharp corners.

Important! The use of any sand leads to the destruction of individual elements of the abrasive mixture. Roughly speaking, extremely fine dust is formed. It enters the respiratory system and causes silicosis, disrupts the work of a variety of equipment.

Therefore, sand treatment must necessarily be carried out under controlled conditions. For example:

- with obligatory equipping of personnel with respiratory protection equipment, working away from complex equipment;

- processing in closed chambers;

- with the selection of air from the zone of emission of the abrasive jet with its subsequent filtration.

Advantages of abrasive

Despite the difficulties of working with sand, this material is one of the most applicable for sandblaster. It has the following advantages:

- inexpensive and very affordable;

- It has low strength properties, performs fairly fine processing, which reduces the risk of irreversible damage to the surface;

- causes little damage and prolongs the life of the sandblaster;

- can be used for surface treatment of non-ferrous metals and soft alloys.

To some extent, the advantage of sand can be considered possibility of secondary use. After sandblasting abrasive residue can be sold or used independently in construction. For example, for the preparation of cement-sand mixture. Some types of raw materials are amenable to screening and can be used again for sandblasting for the cleaning process.

Sand flaws

There are tangible flaws in the sand:

- the formation of a huge amount of dust related to the hazardous factor of production, which requires special remuneration of labor from the employer;

- abrasive consumption for processing one square meter of surface is huge;

- during operation, due to the large amount of dust, visibility is reduced, and as a result, the operator’s ability to precisely perform fine processing;

- additional costs are required for filtering, collecting and disposing of huge volumes.

Despite the listed shortcomings, this abrasive is widely used. Mainly for reasons of availability, low cost and long life nozzles. However, for processing with complex requirements for sandblasting, industrial and artificial sand or other abrasive materials are needed.

Other abrasives for sandblasting equipment

When sandblasting can occur a variety of specific requirements. For example:

- thick removable layer;

- low stiffness, viscosity applied to the surface being cleaned;

- high strength unnecessary on the material layer;

- deep penetration of particles of impurities into the structure of the material being processed.

This list is far from complete. However, it gives a distant picture of the cases that may arise in the work of the master sandblasting. For each of them, qualified personnel can choose one or another special abrasive.

Nickelslag

This material is a product of recycling of metallurgy waste in the production of nickel and slags.Abrasive is different:

- high hardness;

- complex particle shape;

- quartz content less than 1%;

- increased particle mass compared to any quartz sand.

Nicke-slag is a reasonable choice if you need a fairly mild treatment while reducing the hazardous factors of professional activity. During operations with this material is formed little dust. In addition, nickel slag can be sieved and reused. It looks even more profitable if we take into account the small percentage of the destruction of the particles of the abrasive and, consequently, minor losses.

Important! It is possible to sift and reapply nickel slag up to 3 times.

Kupershlak

This abrasive is very similar in properties to nickel slag. This is a product of the processing of slag metallurgy, formed in the production of copper. Differences from nickel slag in the following:

- the mass of particles of Kuperlak is high, the effect on the surface is more intense;

- recovery (reuse) is lower, kuperslak particles are less durable and badly damaged.

Plastic granules

Plastic abrasive is done based on resins. It is melamine (forms the decorative surface of chipboard furniture boards) and amino-aldehyde resins. Both compositions have low strength, therefore with their help extremely fine cleaning is carried out. In this process, the main surface of the material being treated is not harmed.

With the help of plastic granules cleaned wood, plastic, thin metal products. Mainly restoration workswhere it is impossible to apply chemically active substances, solvents. Industrial use of plastic abrasives - cleaning of cultural monuments, antique and collectible items, rare items.

Glass granules

Glass bead processing widely used in industry. With her help:

- gentle cleaning of the surface;

- processing is achieved without changing the color of the material and its physical properties;

- allows to obtain a surface suitable for electroplating operations;

- controlled values of removal are obtained, which is of great importance in high-precision processes of mechanical engineering, optical and other instrumentation, watchmaking.

Glass shot, combining the properties of high stiffness and smoothness of particles, extremely little is destroyed.. In addition, abrasive characteristics make it easy to remove impurities from it after use. Thanks to this, the glass pellets and pellets for sandblasting can re-apply up to 35 times.

Other types of granules and fractions

In order not to dwell on each abrasive in detail, it is worth mentioning only the key properties and features of the use of different types of shot in sandblasting.

- Ceramic Granules and Fractions In general, they are used in the same areas as glass. Show the smallest indicators of destruction, so the abrasive can be reused up to 500 times.

- Chipped iron and steel shot used for intensive exposure to the surface. Used to increase adhesion or local processing, for example, profiling, applying notches.

- Cast steel and cast iron shot they are used not only to clean surfaces, but also to strengthen them with a blow (work hardening), they are used for treatment before electroplating.

- Stainless Steel Fraction Used to clean special alloys, non-ferrous metals. This abrasive has a side effect: treated surfaces, due to the transfer of the smallest particles, acquire corrosion protection or increase their own parameters.

Each type of fraction has recommendations for use. In some cases, extremely high cost-effective sandblasting is achieved. In particular, despite its tangible value, ceramic shot is very economical, since it is used up to 500 times.

Natural Stone Abrasive

Individual countries with sources of extraction of natural stone with high rates of rigidity and fragility offer on the market garnet. This is sand from crushed pomegranate. When sandblasted it does not form a lot of dust. In addition, it is characterized by a complex shape of particles with a multitude of sharp edges, which guarantees an intense, but rather soft impact on the target surface.

According to the abrasive characteristics, the garnet bypasses quartz sand, nickel slag, and kupper slag. Therefore, it is used quite widely.

Electrocorundum

Electrocorundum deliberately placed at the end of the list. This abrasive has record hardness In terms of its properties, it is on the 2nd place in the evaluation table, second only to diamond. The use of electrocorundum shows extremely high economic efficiency.

Abrasive can be collected and reused with almost no loss. At the same time, the intensity of the impact on the surface being treated does not decrease. The particles of electrocorundum have a complex shape with many sharp edges, the edges of which have the ability to self-sharpening.

Important! The market offers both primary, smelted electrocorundum, and recovered. The latter is made from fragments of abrasive wheels and other materials. It is slightly inferior to the primary, may contain impurities, however, is characterized by a lower price and therefore attractive to perform many tasks sandblasting.

Thanks to its unique hardness properties, this abrasive can used to impact virtually all materials. They can matte or engrave stone, glass, slash metal, process ceramics.

Factors affecting the choice of abrasive

Skilled sandblasting masters carefully analyze the capabilities of their instrumental equipment, as well as the characteristics of the target surface for choosing an abrasive. This makes it possible to achieve not only excellent results, but also improve economic performance, increase the service life of the nozzle and other wear components of the installation. The following parameters are being studied.

- Layer removable coating or nature of pollution. The level of strength is being studied. A mistake in choosing, for example, a soft abrasive for a viscous or hard surface will either result in waste of time and materials, or in a bad result.

- The hardness of the target material. The surface of the product should not be severely damaged. Therefore, the selected abrasive should be combined in properties with a cleaned base.

- Target surface finish. If they are not regulated - you can use any hard abrasive. If the surface should be smooth, without dents-chips, it is recommended to choose a working body of the corresponding class.

- Work performance. Abrasives of complex shape (electrocorundum, crushed quartz sand, nickel slag) guarantee the intensity of impact and the rate of removal of coatings.

The last thing that necessarily takes into account and, if possible, provides a careful owner - collection and recovery of waste abrasive material. This allows not only to dramatically improve the economic efficiency of activities, but also to protect personnel and tools from hazards.

Scopes of abrasive materials

Sandblasting today is used very widely. For different types of activity, certain types of abrasives show optimal results.

- At cleaning buildings from decorative colorful coatings, rust of metal parts is great sand. Before using the abrasive, it can be sifted to obtain the desired fraction and good final productivity.

- Copper and aluminum products perfectly cleaned, even in a small workshop, with quartz sand with granules up to 0.3 mm in size.

- Varnishes and paints from metal products can be removed with sand fractions up to 0.6 mm.

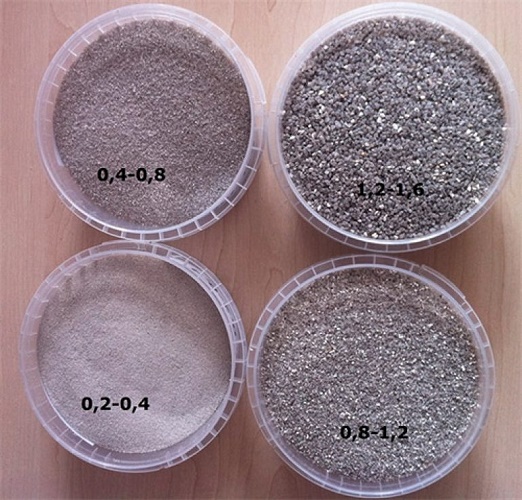

- Scrub rust and scale from billets it is rational to use quartz sand of industrial production or natural material of a large fraction of up to 1.6 mm. Using even more impressive particles (including another abrasive), you can remove bitumen, welding slag, and other thick coatings of low strength.

- Car body It is recommended to process steel, cast iron, cast or cast improved.

- Works on stainless steel surfaces carried out with glass granules or stainless cascade.

Modern works (quite popular and fashionable) for applying patterns and matting areas on glass are carried out with special abrasive mixtures based on quartz sand. The particle size is extremely small. Separate process - tempered glass processing. Its surface of high strength is treated only with electrocorundum.

As a conclusion

The above description of the sandblasting process is rather relative. In practice, there are dozens of varieties of operations. Along with air, liquids are applied. In certain conditions, the sandblasting machine can be used to cut various materials, to trim the edges in the cut zone, for other tasks.Even such a brief description of the possibilities shows how important it is to choose the type of abrasive and carefully analyze all the parameters of the upcoming processing operation.

/rating_off.png)