How to fix the main problems with a chainsaw do it yourself

Despite the simplicity of the design of the chainsaw, with interruptions in its work, and sometimes with the complete failure of the unit is quite difficult to find the cause of the problem. Of course, an experienced master will immediately be able to determine what led to this or that failure. But to the average user, in order to find malfunctioning chainsaws and repair themselves, it will be necessary to study the symptoms that are inherent in one or another failure.

Content

Malfunction of chainsaw engine

The engine is the main node of the chainsaw, and most of the failures occurring in it are associated with the petrol drive.Correct diagnostics is able to determine the causes and methods of troubleshooting even to an unprepared user.

The main problems with starting the engine can be the following:

- engine does not start;

- works unstable;

- a start occurs, after which the unit stalls immediately;

- stalls under load.

Ignition system malfunctions

First of all, the reason that the chainsaw does not start should be sought in the ignition system of the unit. Need to start with checking candles, because there is a possibility that the spark is gone.

According to the condition of the twisted candle you can determine how the fuel system works. The candle is twisted with a special key.

The following figure shows 3 options for the state of the spark plug.

Splattered candle talks about its excess in the cylinder. If the candle fills, then the carburetor is most likely incorrectly adjusted, or the engine start rules have been violated. Candle must be well wiped and dried. You should also drain the combustion chamber:

- cut off the fuel supply;

- when the candle is unscrewed, pull the starter several times so that all gasoline is removed from the cylinder:

- set the candle in place and adjust the carburetor according to the instructions.

A large amount of soot on the candle caused by the wrong ratio between oil and gasoline during the preparation of the fuel mixture, as well as problems in the fuel supply system. If the mixture is prepared correctly, using high-quality oil, then the carburetor should be adjusted. Candle with soot should be cleaned by washing in gasoline. After that, it is necessary to wipe it dry, with a needle to remove the remains of burning and clean the electrodes with fine emery paper.

You should also check the candle for proper clearance between the electrodes. Normally, the spark gap should be between 0.5 and 0.65 mm.

If a the candle is dry, it is required to check the presence of a spark on its electrodes in order to exclude a malfunction of the ignition system.

- Put a cap with a high-voltage cable on the candle.

- Holding the cap, attach the candle threads to the cylinder.

- Pull the starter handle a few times and see if a spark slips between the electrodes. Normally, the spark should be bright. A weak spark indicates a possible malfunction in the ignition coil or in the spark plug itself.

If there is a spark, then the problem must be sought in the fuel system. No spark - the reason may lie in the candle itself (needs to be replaced) or the ignition system. The absence of a spark can cause a damaged cable, which should be checked by “ringing” the tester. With a good wire, you need to move on - check the ignition module. A malfunction of the ignition coil or an incorrect gap between it and the magnet can also be caused by the fact that a spark has disappeared.

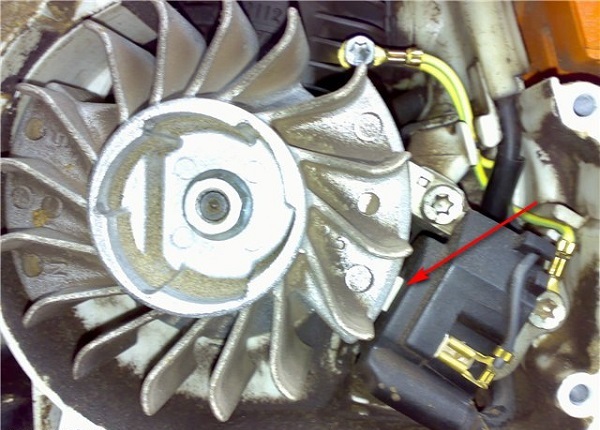

The ignition on the chainsaw is simple: a permanent magnet is attached to the motor shaft. A coil is fixed near it under a certain gap. When the magnet rotates in the coil, an electric current is generated, which is supplied to the electrodes of the candle. In the next photo, the arrow shows where correct gap between the coil and the magnet.

The gap between these parts should be 0.2-0.4 mm. The walls of an ordinary plastic bottle have such a thickness, and a template (probe) can be made from it by cutting off a small strip.

The clearance is set as follows:

- unscrew the screws holding the coil;

- lay a template between the magnet and the coil;

- lightly press the coil against the magnet;

- tighten the spool mounting screws and remove the template.

Malfunctions of the fuel system

If the chainsaw does not start well, and the ignition system is OK, then you need to check the entire fuel system of the unit. First of all, it is required adjust the fuel supply into the cylinder of the engine through the carburetor, properly setting it up.

Next, you need to watch how the chainsaw behaves.

- The device stalls after launch. If you prepare the fuel mixture incorrectly, adding more oil than it should be, then the unit will immediately stall or work only on the suction.

- Engine stalls at idle. This is a sign of a silenced muffler (carbon removal is required), a clogged air filter (wash), incorrect carburetor settings.

- The unit stalls at maximum speed. Contaminated fuel or air filter, which must be well cleaned. Often, this behavior of the engine can cause a clogged gas tank breather. It is cleaned with an ordinary needle. In addition, the failure of the diaphragm, acting as a fuel pump, may also prevent the engine from gaining maximum speed.You will need to disassemble the carburetor and replace the membrane if it has lost elasticity.

- Chainsaw stops working under load. This is a sign of improper carburetor adjustment, improperly prepared mixture, or a dirty air filter.

- Fuel injection does not work. If the primer does not pump gasoline, and it happens, most often, after a long interruption in the operation of the unit, then you need to check the carburetor. It looks like, and where is the primer on the Husqvarna chainsaw, shown in the following photo.

Inside the carburetor there is a spray valve that can stick when the fuel is around for a long time. To eliminate the malfunction, it is necessary to thoroughly wash the carburetor with gasoline or flushing fluid, and then blow all the holes through with compressed air. - The chainsaw won't start up hot. If you, having drowned out the chainsaw, unsuccessfully trying to start it after a short period of time, in most cases this is caused by a loss of compression in the piston group.

Compression is checked with a compressometer, which is screwed into the cylinder instead of the spark plug. Next, you need to pull the starter and watch the instrument readings.Normally, a new chainsaw shows compression ranging from 8 to 12 atmospheres. If the indicator is below 8 atmospheres, the engine will not work.

Compression may disappear due to scratches on the inside of the cylinder and the side surface of the piston. In this case, you have to change the entire piston group.

Chainsaw Chain Problems

In addition to problems with the engine, the chainsaw may experience problems in operation due to malfunction of the cutting (sawing) unit consisting of the oil pump, tire and saw chain.

There is no oil on the tire.

Usually, if there is no oil flowing onto the chainsaw chain, it is required to check the channels through which the oil is supplied to the tire and clean them from contamination. If the previous steps did not reveal the cause of the malfunction, you will have to check the oil pump. For this you need:

- remove part of the chain cover;

- remove the clutch;

- unscrewing the 3 screws, remove the cover hiding the pump;

- Get to the worm gear, which rotates the pump shaft.

If the thread on it is worn, the shaft does not rotate, the pump does not work, the chain is not lubricated. Worn gear must be replaced. You can also pull out the oil pump itself and manually try to pump oil through it. If it is not pumped, the pump should be replaced.

Chainsaw oil filter

Remember to remove the oil filter from the reservoir and clean it if necessary.

Also lack of lubrication can be the reason for its leakage. It is necessary to check how tightly the pipes coming from the oil pump are connected. If the tightness is broken, the tubes are replaced with new ones.

Chain breaks

If the chain broke during operation of the chainsaw, then this could have happened if it hit a hard object, for example, a nail. If the chain is constantly broken, then the reasons may be as follows.

- Low quality metalfrom which the saw chain is made. It is necessary to buy saws for gas cutters from famous brands.

- Overheating circuit due to bad lubrication. As a result, the saw overheats, the properties of the metal change, and it breaks under load. Requires checking the entire lubrication system of the chainsaw (discussed above).

Also about the causes of frequent chain breaks can be found out from this. video.

The chain does not spin

This trouble often haunts inexperienced chainsaws owners. They forget after starting the engine remove the brake. As a result, the chain does not spin, the brake system overheats, and the clutch mechanism fails.The problem is solved by removing the saw from the brake. If the clutch does not “burn out”, you will notice the rotation of the chain. Otherwise, the clutch mechanism will need to be replaced.

The chain quickly dies

Basically, the reason that the chain is quickly blunt is poor quality saw. Trying to save on the purchase of branded chains, the chainsaws owners buy saws of unknown manufacturers, or, due to inexperience, acquire counterfeits for well-known brands. It is best to buy a cutting element for gasoline cutters in retail stores. The Stihl saw chains are very popular among the owners of this technology.

The chain does not stop

If, when operating with a chainsaw, you notice that the saw chain does not stop at the right moment, then this failure can have 2 options.

- Dirty brake tape. During the work of a saw under a tape dirt, sawdust, dust, etc. can get. As a result, the brake is blocked and the circuit does not stop when the gas is released. The problem is solved by cleaning this node.

- Worn brake tape. It is necessary to replace this element of the brake system.

The chain cleaves

This happens when drive or driven sprocket wears out. The chain usually starts to wedge under load. But without a load, the saw can rotate. The photo below shows a worn driving chain saw star.

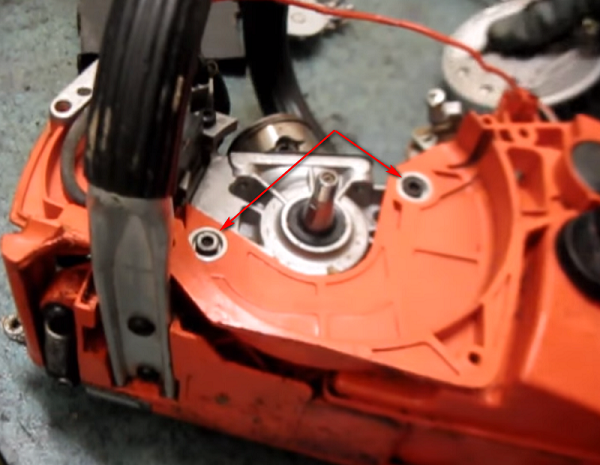

The next photo shows that the reason why the chain is wedged must be found in the location of the driven sprocket.

But what to do if the chainsaw is completely jammed and all attempts to pull the starter to no avail? Such a malfunction is sometimes found on Chinese-made chainsaws. It is called unscrewed from the vibration of the bolts, which screw the engine to the plastic casing of the unit. These bolts are located right under the flywheel (magneto). In the photo below, the arrows indicate the location of the problem bolts.

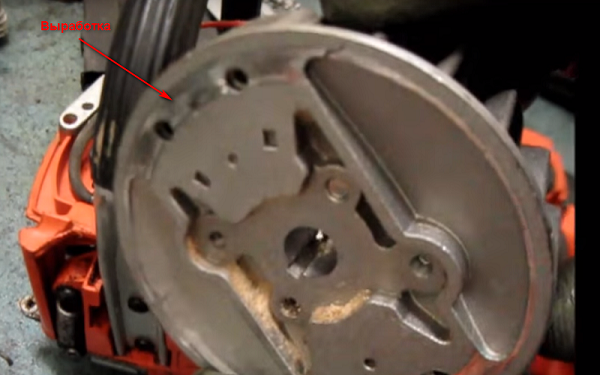

Getting out, they begin to rub on the flywheel and can completely jam the chainsaw. The following photo shows a flywheel with existing scuffs from bolts.

To eliminate the problem, you need to remove the flywheel from the motor shaft and tighten the bolts.

Chainsaw crooked saws

This problem may occur if the circuit is blunt or incorrectly sharpened. This, to a greater extent, applies to new chainsaws. But if worn tirethen even after replacing the chain, you will notice that the saw leads away.Tire wear can be easily determined by placing it on a flat table and placing a square on it, as shown in the following photo.

In this case, you can see that there is a gap of about 2 mm between the tire and the corner. It is because of such one-sided wear of the tire chainsaw saws crooked. The problem is solved only by replacing the tire with a new one.

Important: in order to extend the service life of a chainsaw tire, it needs to be removed and turned over from time to time. Due to this, the tire will wear more evenly and will not cause chain skewing.

Why chainsaw is heated

The new chainsaw heats up, because all parts of the piston group have not yet gotten used. Therefore, the unit must be run-in, during which it is impossible to prevent overheating of the engine. If the unit is already run in, overheating of the engine may cause late ignition, of course, provided that the combustible mixture was prepared without disturbing the proportions. To fix the problem, you need to adjust the ignition system of the device.

Why is oil flowing

Many chainsaw owners are faced with such a problem as oil leakage from under the unit. Most often, oil flows due to damage to the oil hose connected to the oil pump. The photo below shows exactly the case when the end of the hose broke and does not fit tightly on the pump nozzle.

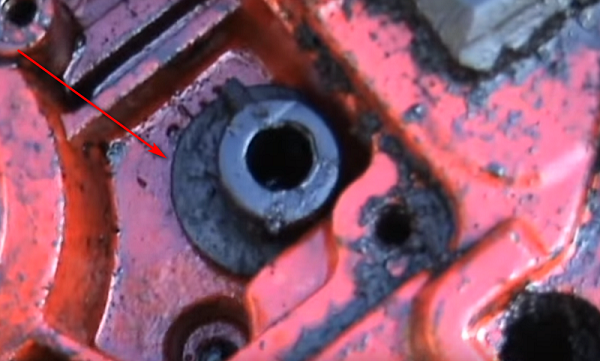

But to get to this place, you need to remove the clutch mechanism from the shaft. In some models of chainsaws, oil may leak out at the junction of the oil pump with the hose of the oil tank (indicated by the arrow in the photo).

To eliminate the leakage of grease, you will need to pull the hose from the landing site. To do this, you can use pliers, pulling on the outer part of it. At the end of the hose you will see rubber stopperwhich is the cause of the leakage of oil. This cork must be wiped well to remove the remaining oil, after which its seat must be sealed with something. You can use automotive sealant or fum tape, as shown in the following photo.

Next, insert the hose into the hole, put the plug back in place and seal it using a flat screwdriver. At this operation to eliminate oil leakage can be considered completed.

/rating_off.png)