What can be done from the screwdriver with your own hands

The screwdriver is widely used in various fields of activity for working with various types of fasteners: screws, screws, bolts with nuts, furniture confirmatories, screws and others. Also, with the help of this power tool, the holes in various materials, for example, in various metals, in sawn timber, in concrete, will be rolled up. At the same time, the functional capabilities of the model being operated are determined by the magnitude of its power and torque, the presence of the impact function.

From a screwdriver, you can make at home a variety of appliances and tools for domestic use. In addition to the power tool itself, in many cases additional parts and materials will be required. But home-made devices will still be cheaper than factory-made counterparts, allowing you to automate and make manual labor more efficient.

Content

- 1 Ideas homemade equipment from a screwdriver

- 2 Assembling a manual camp electric generator and a self-made wind generator

- 3 Alteration of the screwdriver in the Bulgarian

- 4 Conversion of the screwdriver into a trimmer or lawn mower

- 5 Assembly engraver

- 6 Making a garden shredder

- 7 Screwdrivers

- 8 Other non-standard ways to use the tool

Ideas homemade equipment from a screwdriver

The entire range of screwdrivers is divided into network and battery models. Both types of products operate at the expense of electrical energy, which causes the motor to rotate. Only the electric motor itself in network devices is designed for alternating voltage of 220 V, and in battery technology for a constant different size, for example, 12 V, 14.4 V. These design features, together with the technical characteristics, largely determine which homemade tools from the screwdriver will be able to assemble .

Electricity is one of the main types of energy used by mankind. Electricity operates household appliances, industrial equipment, machine tools, power tools.The work is performed while the electric motors of different designs and power, which are powered by alternating or direct types of current. For this reason, the following technical devices can be assembled on the basis of a screwdriver or from its individual parts:

- garden shredder of grass and twigs;

- trimmer (electrocosm);

- marching hand generator;

- engraver (mini-drill, dremel, bormashinka);

- wind generator;

- lawn mower;

- Bulgarian;

- mini-machines: drilling, grinding, reysmusovy, turning, sawing, grinding;

- rebar tying tool;

- gate opening drive;

- vehicles for children: quad bike, scooter;

- small ice screw, yamobur, construction or kitchen mixer.

A powerful percussion model can also be converted into a tamper for concrete with a special nozzle.

The implementation of each option takes a different time and requires additional (minor) costs, or it costs them without them at all.

Assembling a manual camp electric generator and a self-made wind generator

It will not be difficult to make a home-made generator out of accumulator models of the instrument, which will produce electricity when the hand is attached by turning the handle. Such a device is useful in field conditions.To make a dynamo machine, it is not necessary to radically modify the product. Everything you need to create a marching generator in the design of the device already exists, only minor improvements will be needed.

With the help of the created equipment it will be possible to charge 6 or 12 V batteries.

Power tool for rework with an operating voltage of 18V and above. The modification is carried out in the following way:

- disassemble the electric screwdriver;

- gently solder the electronic board;

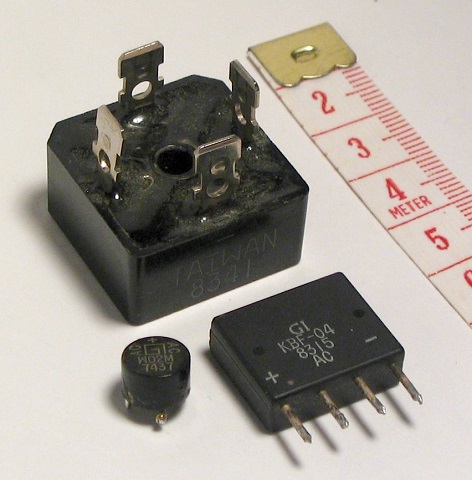

- instead of batteries, a diode bridge suitable for parameters (dimensions, technical characteristics) is installed inside the battery case;

- make a comfortable handle with a handle;

- the end without the handle is fixed in the cartridge.

The final construction after the done manipulations will look like in the photo below.

The diode bridge is necessary so that the handle of the electric generator can be turned in any direction. Instead of the handle, you can insert the nozzle with blades. Then get a simple wind turbine.

Wind power generator, also made in another way, in the form of a weather vane.In this case, with the battery device do the following:

- disassemble the screwdriver;

- take out the electric motor by disconnecting its contacts;

- remove the cartridge with gear (rotor part);

- insert the motor shaft into the cartridge, clamping it;

- a round metal plate about 1 mm thick is attached to the gear of the reducer with bolts, which will serve as a basis for fixing the blades made, for example, from plastic pipes;

- clamp with clamp put on the shaft between the chuck and gear;

- cut out of plywood or thin metal rectangular base;

- by means of a clamp with a collar, an engine with a cartridge is attached to it, drilling holes in the right places for fastening;

- make a casing to protect the wind generator (from precipitation, dust and other unforeseen impacts), for example, from under the coffee can;

- insert the base with the engine and the cartridge inside, fastening the elements with glue, and the cover - sealant;

- make the blades, attaching them to the round plate of the unit;

- make a weather vane;

- an assembled generator is mounted on one of its ends;

- connect the wiring to the outlets of the motor;

- check the output voltage with a multimeter by rotating the blades by hand.

Wind turbine options are many. Even the whole screwdriver is attached to the support, providing it with a nozzle with blades.

Alteration of the screwdriver in the Bulgarian

If the angle grinder is broken or it is completely absent, then it can temporarily be replaced with a battery or network electric screwdriver. However, there are various options for redoing. The easiest way is to use ready-made or homemade nozzles or adapters. An example of the adapter is shown in the photo below. Its one end is fixed in the cartridge, and the disk clings to the other.

Another option that allows you to convert a drill-screwdriver into a grinder is to use a special type of nozzle, equipped with gear. When implementing the method, the power tool is disassembled, its gearbox is dismantled, and the nozzle is installed instead. After the transformation, you get a tool that looks similar to an angle grinder.

It should be taken into account that such a special nozzle is expensive, and the work on modification requires a lot of time.

Self-made nozzles are made from studs of suitable diameter, nuts and washers.They are even used with rechargeable electric screwdrivers.

The performance of homemade products is much lower than that of the factory Bulgarians. This is due to the large difference in the speeds of rotation of the nozzles: about 3000 rpm for a screwdriver versus about 11000 rpm for an angle grinder. A small amount of power, together with a small speed, significantly limits the functionality of the device.

Made devices should be used only in emergency situations. because of reverse options on the tool to be reworked, it is necessary to monitor the direction of rotation of the disc in order not to be injured.

Conversion of the screwdriver into a trimmer or lawn mower

To do an electrocosm yourself, you need the following parts and materials:

- a piece of plastic pipe about 2 m long;

- soldering iron with a set for soldering;

- fasteners: screws, bolts with nuts;

- 45 degrees plastic corner;

- pipe plug;

- 12 V motor from electric screwdriver and rechargeable battery from it;

- the wire;

- adapter from 40 to 50 mm for plastic pipes;

- power button;

- plastic bucket;

- contact clips (crocodiles) - 2 pcs;

- office knife blades.

In work the pipe and a corner to it with a diameter of 40 mm are used.

The alteration process is carried out as follows:

- having disassembled the electric screwdriver, get a motor;

- attach it to the cap, noting previously and drilling in it the mounting holes;

- attach 2 screws to the electric motor;

- solder output to the motor;

- install an electric motor, pushing his wiring in the pipe;

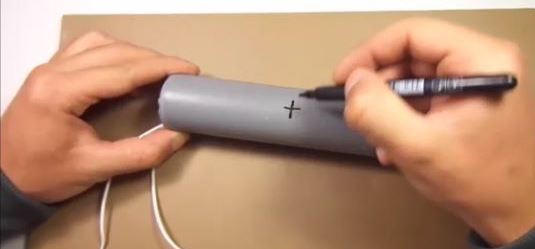

- mark the location of the future switch with a marker on the tube;

- drill a hole;

- connect to the switch wiring, mount it;

- connect the terminals to the outgoing wires to allow quick connection to the battery;

- from the adapter make the battery holder;

- connect the drive, connect the adapter with the tube;

- make knives from blades;

- using a common terminal clamp, the nozzle is connected to the motor shaft;

- a protective casing is made of a plastic bucket;

- glue the part to the pipe;

- check the performance of the structure.

The created device will allow mowing only grass cover with soft stems. There are a lot of different variants of lawn mowers on the basis of network models of drills-screwdrivers.The photos below show two homemade items.

First, a base is created from metal, plywood or other materials, to which wheels are attached, as well as a control stick. Clamps or to the rack fix electric. Insert the cutting nozzle into the cartridge. To protect the feet from scattering grass, a cover is attached to the back of the base. Power is done through a button or directly from the network.

To collect a fairly functional lawn mower, you need to take a drill-screwdriver from 0.5 kW power.

Assembly engraver

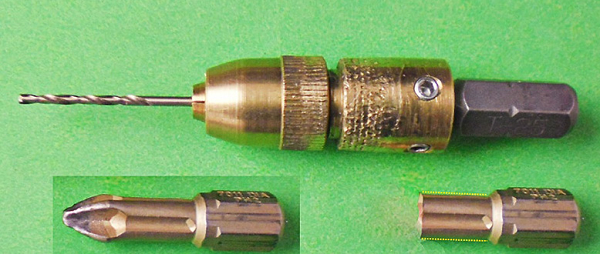

A cordless or network model of an electric screwdriver can be turned into an engraver, which is otherwise called a Dremel, a drill, a mini-drill, a straight grinder. To do this, simply buy a nozzle in the store and grind any bat under it.

Self-made cartridge will allow you to use a variety of tooling designed for Dremel.

The process of creating an engraver with a flexible shaft shows the following video.

Making a garden shredder

A garden shredder for grass and thin branches (less than 1 cm thick) can be made on the basis of a power drill / screwdriver.

It is recommended to use models with a capacity of more than 0.5 kW.

Create an aggregate like this:

- choose a suitable container, for example, zinc evaporation;

- a hole is drilled through the center of the bottom for a shaft on which a knife or several blades will be fixed;

- make a wooden or metal frame to install the container or put it on the edge of the table;

- to the frame or bottom of the welding attach a drill-screwdriver, which is equipped with knives;

- mount on / off button;

- make a side cut in the tank - cut a rectangle in front of the bottom 10 by 20 cm;

- a sleeve is made of tin for the release of crushed plants;

- attach it to the container;

- check the performance of the unit.

Knives the easiest to make of hacksaw blades. Install them to be sharpened down. In this case, you can make several versions of the blades for different herbs. If you make to the drill-screwdriver nozzle in the form of knives, the grass can be simply chopped in a bucket or other suitable container.

Screwdrivers

The craftsmen made many different machines for the purpose of the screwdriver. They quite cope with everyday tasks.

If you need to work professionally, you can not do without more serious equipment.

One of the options for how to alter the drill-screwdriver in the drilling machinedemonstrated on the video below.

The way to create the simplest lathe shown in the video below.

Also on the basis of the drill-screwdriver it is possible to assemble the simplest milling and grinding machines, which is shown in the following videos.

Other non-standard ways to use the tool

Non-standard use of the screwdriver is not limited to the options considered. The video below shows how to use this power tool as drive for quad and for opening doors (gates), for drilling ice, as a mixer. Also video contains other unconventional options.

Using the case with the battery, you can make a good flashlight. Whole build process led downlight shows the video below.

How to adjust the screwdriver to make electric bike shown in the videos below.

Another option for a bike with a motor contains a roller further.

Using the hook inserted into the screwdriver cartridge, you can knit reinforcement in the construction of various objects. How this is done shows the following video.

Having connected the tool to the screw of the manual meat grinder, it is possible to automate the process of twisting vegetables and meat.

Keep in mind that homemade products of this kind are often very limited in load. But if they do not turn out to be of practical use, then entertainment is guaranteed.

This unconventional use of the screwdriver is not limited. Folk craftsmen are constantly putting forward new ideas, at the same time their practical implementation takes place. Other specialists adapt home-made devices for their own needs, while receiving various modifications of home-made equipment. You can also come up with something yourself, showing technical knowledge and imagination, giving free rein to imagination and creativity. The main thing to remember: when starting to manufacture various devices, it is imperative to take into account that the mechanisms created are safe.

/rating_off.png)