Proper use of the screwdriver

The screwdriver successfully replaced not only various types of screwdrivers, but also wrenches, hex keys. Also this tool is used instead of a drill. For builders with furniture makers, an electric screwdriver has become an indispensable assistant. For him, and at home is always the application. The range on the market is represented by a large variety of models. Despite the prevalence of screwdrivers in various fields of activity, not all users, especially beginners, know how to operate it. Proper use, maintenance and storage of power tools will extend to the maximum its service life.

Content

The device and the principle of operation of the screwdriver

According to the power supply method, screwdrivers are divided into two types:

- network, connected to the network voltage of 220 V;

- rechargeable, using the energy of the accumulated charge.

Recently, there are also tools with a combined method of power. They combine all the benefits of both varieties.

External and internal device network and battery models are almost the same. In general, a power tool consists of the following structural elements:

- enclosures;

- cartridge;

- power button;

- switch of the direction of rotation of the electric motor (reverse);

- speed controller (number of revolutions);

- power on lock buttons;

- Tightening force regulator (torque value switch).

The photo below shows the construction of a cordless type screwdriver.

A number of models in addition equipped with backlightwhich is constructively implemented in different ways. Not every product has a speed controller and a power lock button.Network electric screwdrivers have a power cord, and battery packs have a charge drive installed instead.

Power tool housing most often made of plastic, much less often - from alloys of different metals. For convenience, it usually consists of 2 halves. Inside the case are these main parts:

- electric motor (direct or alternating current);

- pay;

- capacitor;

- gearbox;

- coupling

The wiring diagram depends on the model.

Electric screwdriver can be equipped with cartridges of different types. The most widespread keyless three-jaw version of this part. The cartridge also consists of individual parts, which are presented in the following photo.

It should be taken into account that if the purpose of the screwdriver is highly specialized, this may introduce some design changes.

Pprinciple of work both network and cordless screwdrivers are the same. It lies in the fact that electrical energy causes the motor to rotate. Through the gearbox and the shaft, the force and speed is transmitted from the motor to the attachment fixed in the cartridge.She already drills a hole or twists or twists fasteners. The peculiarity of the process is that the electric model of the network models operates at an alternating voltage of 220 V, and at the battery ones - at a constant voltage, the value of which can be in the range from 3.5 V to 36 V.

Perform nozzle change

Change the nozzle on the screwdriver is not difficult. The tool can be equipped with a quick-release chuck or turnkey chuck. Replace tooling in both cases in a similar way. To pull the drill out of the screwdriver with keyless chuck and insert a new or other type of snap-in as follows:

- first, a bit is selected for the size of the cap and the type of slot on it (cross, straight or other) or a drill of the required diameter corresponding to the material in which the hole is to be created;

- spins the cartridge against the hour direction;

- in the center, between divorced cams, establish the chosen type of equipment;

- rotating the cartridge case in the direction of the watch, clamp the nozzle.

Pull the drill out of the screwdriver (or another nozzle) by holding the moving part of the chuck with one hand and pressing the trigger button with the other. Only pre-switch the direction of rotation to unwinding.

When the drill driver is equipped with a chuck Full construction, then, to change the snap do:

- inserting the key into the recess for it, spin up the cartridge;

- I install the nozzle;

- clamp it, rotating the key in the clockwise direction.

There are models in which you can remove a cartridge of the same type, for example, quick-release, and replace it with a turnkey analog. When choosing an option, you need to focus not only on convenience when working, but you should also consider the pros and cons of each of them. So, the turnkey chuck firmly clamps the snap-in, which is important when drilling, and the quick-clamping one allows for quicker replacement, even with one hand (with the other holding the handle while pressing the start button as necessary).

Screwdriver application

To use a screwdriver correctly is to perform with it only those operations that are indicated in operating instructions manufacturer of this product. The main (by appointment) for this tool is such types of work:

- screwing or unscrewing fasteners of various kinds, including tightening and unwinding of bolts with nuts;

- drilling holes in different hardness materials.

Using a screwdriver for its intended purpose is the most common way to use this device, both at home and in construction, furniture manufacturing, wiring, during assembly and repair of cars. The scope of the product is not limited to these areas: the drill-screwdriver is useful wherever you need to work with fasteners (assemble to disassemble different designs, equipment, machines) and drill holes of relatively small size.

The scope of a specific model is determined by which category it belongs to: household or professional. A tool designed for home use, is relatively cheap, has a small power and torque. Household models have low productivity as well as limited functionality.

Drill-screwdriver from professional category has advanced functionality and high technical performance. Such a tool is designed for long-term, effective use for its intended purpose.It also has much broader opportunities for unconventional exploitation.

Unconventional Uses

In addition to the direct appointment of an electric screwdriver is used to perform various unconventional operations. These include the following types of work:

- polishing cars and its headlights;

- mixing small amounts of various building mixtures and paints;

- drilling holes in the ice (for this tool is equipped with a special nozzle - the drill);

- mating reinforcement;

- thread cutting;

- grass mowing (for this purpose, the device is reworked into a trimmer or lawn mower, or simply inserted into the cartridge nozzle with blades);

- grinding soft grass or thin branches (for this, a garden shredder is created on the basis of a drill / screwdriver);

- surface grinding;

- cutting materials;

- twisted wires.

This is far from an exhaustive list of unconventional work performed using battery-powered or network-based electric screwdrivers. Inventive thought does not stand still. Practically every specialist has options that are not typical for this power tool.

With the help of a screwdriver, you can return the car its original color and shine. To polish the machine, apply these types of nozzles:

- leather or fabric circles, with their help perform the initial cleaning of surfaces;

- felt - they are used for initial processing and finishing polishing (suitable nozzles made of sheepskin);

- foam rubber.

Along with the equipment, polishing pastes and polishes are also used. They are of the following types:

- silicone;

- abrasive;

- non-abrasive.

Using similar tools is carried out and polished headlights.

The quality of the achieved result is determined by the correct combination of nozzles with polishing agents, as well as the accuracy and skill of the job.

Knitting rebar With the help of steel wire is very common in the construction industry in the construction of reinforced concrete (monolithic) structures, for example, foundations, houses. Even if you have to perform a small amount of work, then working with a hand hook or pliers is not quite productive. Much more quickly will help to knit the battery armature or network electric screwdriver, equipped with a nozzle in the form of a hook. At the same time, the power indicator of the tool is not particularly important.

Twisting the cut ends of the wiresFor example, in distribution boxes, this is also a fairly routine job. You can speed up the process with a screwdriver with a special nozzle. How to twist, shown in the video below:

Features of drilling by the screw gun of concrete, metal, brick

Using electric screwdrivers, drill wood, metal, concrete and other materials. At the same time, the functionality of the model used depends on its technical indicators: power, size, torque, availability of impact mode, speed. The instruction manual contains precise instructions on whether it is possible to drill with a screwdriver this or that material. It also provides the maximum diameter of holes created, and in some cases the depth limit.

Brick or concrete wall able to drill only powerful enough drill-screwdriver. In most cases, such devices can operate in shock mode. But to drill a concrete wall with a screwdriver, even of a hammer type, is quite problematic. This tool is suitable for single operations only.This time-consuming work is best done using a punch.

In soft woods even rechargeable products from the household category are capable of creating openings with a cross section of up to 20 mm. With the help of budget models from the ranking of the best electric screwdrivers of 2017, various metals are drilled, including steel. At the same time, holes in diameter can reach 10 mm.

For drilling each material used a certain type of drill. Nozzles differ not only in the material from which they are made, but also in their design and sharpening.

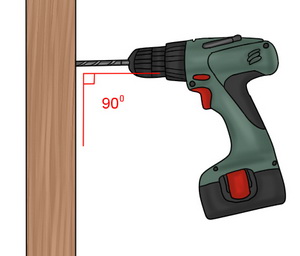

When working with the tool, the rotating drill should enter the material surface perpendicular to it - this allows you to evenly distribute the load on the tooling, to create more accurate holes.

When drilling metal It is recommended to make a small recess in the center of the future hole using a core. This will prevent the drill from sliding on a smooth metal surface. If you need to make a hole of a sufficiently large diameter, then you should pre-drill a smaller one. Also during work with metal, the nozzle is recommended to be regularly lubricated with a special compound.

Using a drill-screwdriver, it should be borne in mind that it is impossible to exert strong pressure on it, because this not only does not accelerate the performance of work, but can also damage the drill and the power tool itself. Effort must be maintained constantly at the same level. To avoid jamming or breakage of the nozzle, you need to get it out of the drilled hole only during rotation. If, however, the drill is stuck, then you can get it by performing a reverse.

Drilling small parts It is recommended to carry out, having previously fixed them in a vice. If you have to make a through hole in a thin sheet of metal or in a thin wooden blank, then you need to fit even pieces of plywood or boards under them.

Recommendations for proper care tool

Both rechargeable and network models require periodic maintenance and constant maintenance. Together with the proper storage and lack of operational overloads, these factors can extend the life of the screwdriver.

Quality care is as follows:

- Water must not fall on the instrument. Therefore, you should store the product in a designated, dry place.

- It is forbidden to throw an electric screwdriver.

- Do not overload the power tool: you can at the same time be guided in part by heating the case. It is necessary to use only sharp drills.

- Must be run periodically cartridge lubrication: the regularity of the event is indicated in the operating instructions.

- At hit of dirt, dust, sticking of shavings and other pollutants - they should be removed with a dry cloth (especially carefully combustible-lubricating materials). You also need to wipe the device used at the end of the day. Snap-in must also always be in a clean state.

- Batteries should be stored so that a short circuit does not occur between their terminals. Do not allow deformations of the drives, as well as leave them under direct exposure to sunlight.

- Lithium-ion type batteries are recommended to be stored half-charged from the maximum capacity, nickel-metal hydride batteries are fully charged, and nickel-cadmium batteries are partially discharged (but only slightly).

- Nickel-cadmium accumulators after storage (or new ones) should be subjected to 3 full charge / discharge cycles before use, so that they retain their capacity, and nickel metal hydride - 4-5.

- Manufacturers recommend storing and operating electric screwdrivers at temperatures from -5 to +30 degrees.

- Charger from battery models after charging the batteries must be disconnected to avoid overheating.

- Before and after work, it is recommended to check the integrity of the product being operated, especially its moving part.

- When drilling is recommended periodically cool the nozzle different ways.

Compliance with the above care recommendations does not take much time, but it contributes to a significant extension of the period of use of the product.

Before you start using a new screwdriver, it is recommended that you first familiarize yourself with the operating instructions for it from the manufacturer. It already indicates the design features of the model, its technical characteristics, suitable scope, frequency of service, recommendations for transportation and storage. Also be sure to include safety rules that should be followed.

If during the work of a tool there is a smell of meltable plastic or insulation, smoke, unusual noise, excessive vibration,then you should stop exploiting it immediately.

When the product is under warranty, it is better to take it to the service. Otherwise, you can try to repair it yourself.

/rating_off.png)