Rules for working with a concrete mixer and do it yourself repair

A concrete mixer is an equipment intended for the preparation of various mortars and the mixing of dry mixes. Its application provides high performance work. At the same time, in comparison with the manual method, a higher quality finished material is obtained at the exit. But in order to achieve this, it is necessary to correctly knead the concrete or another composition, observing the proportional ratios between its components and the sequence of their addition. On the market there are concrete mixers of a different principle of action. This affects the maximum size of the filler fractions, which will be mixed when preparing the solution.

Content

Device and principle of operation of the concrete mixer

Effective work with a concrete mixer requires knowledge of its design. This is necessary in order to be able, if necessary, to repair the independently used model of equipment and properly perform its maintenance.

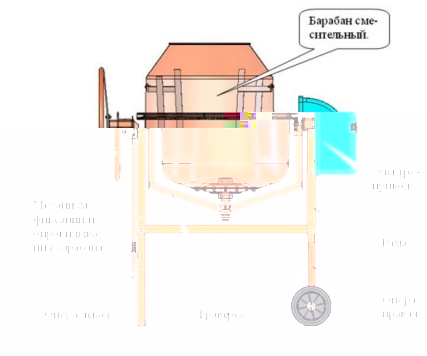

The device of any concrete mixer provides for the presence of the following common structural parts:

- containers (drum) for mixing the solution;

- frames, which is a steel supporting structure on which all other elements of the concrete mixer are fixed;

- bladesdesigned to mix concrete or other mixtures and prevent them from sticking to the container walls;

- the drive with a transmission mechanism and control system.

These structural elements are presented in the photo below.

The metal drum may be of different shapes, for example, cylindrical, pear-shaped, barrel-shaped.

The concrete mixer can work by muscular strength, either due to the presence of an electric motor or an internal combustion engine. In the first case, the drum drives the worker, turning the special handle. But mechanical versions of the equipment are quite rare. The most widespread units with electric motors. They are equipped with a pushbutton post, through which the operation of the mechanisms is controlled. The power of the installed drive determines the purpose of the equipment for domestic or professional use.

According to the installation method, concrete mixers are divided into stationary and mobile models. The latter are supplied with wheels for easy transportation.

According to the method of mixing mortar mixers are of two types:

- gravitational;

- forced.

The principle of operation of a gravitational type concrete mixer is based on raising the stirred mixture with a rotating drum and its subsequent fall under the influence of gravity.. In this case the fixed blades placed inside the tank additionally separate the composition, contributing to the more rapid formation of a homogeneous mass.The material is unloaded through the loading opening by means of a tilting drum mechanism set in motion by a wheel or lever.

Rotation from the motor to the capacitance of gravity models is transmitted through a reducer or a crown.

Forced Concrete Mixer works as a mixer: inside a stationary drum, the shaft with blades mixes the solution. Unloading of the finished composition occurs through a sliding gate, which is located on the bottom of the tank. The shaft can be positioned horizontally or vertically (shown in the photo above). Forced action models are equipped with more powerful electric motors than gravitational ones, and also cost more.

Performance Mixer

The performance of a concrete mixer, both gravity and force, is determined by the following factors:

- mixing time of the solution until ready;

- drum volume;

- electric motor power;

- unloading time of the material;

- the number of batches that can be prepared within an hour.

Mixing time is specified by the manufacturer of the equipment in the operating instructions for it.A batch that occurs in about 2-3 minutes is considered fast.

Power magnitude determines the number of hours during which the concrete mixer can be operated without overloading the motor. To calculate how much concrete can be kneaded by a concrete mixer per day, you need to perform these simple mathematical operations:

- add up the duration of loading, mixing and unloading;

- determine the number of batches per hour by dividing 60 minutes by the figure obtained in the paragraph above;

- find the volume of the finished material for 1 hour by multiplying the drum capacity by the calculated number of batches;

- multiply the hourly productivity by the allowable number of working hours per day.

The productivity of gravity aggregates is comparable with compulsory counterparts with similar technical characteristics, in which the shaft is located vertically. For models with a horizontal shaft, the performance is lower. This is due to the fact that their shipping process takes more time.

Proper preparation of concrete mix

Filling the foundation, screed floor, laying floor slabs, bricks, cinder block and many more construction and repair work associated with the need to prepare a concrete solution in large quantities.At the same time, it is necessary to properly mix concrete in the concrete mixer so that it turns out to be of good quality. In this case, after pouring and ramming, you get a solid monolith.

Proper preparation of concrete is as follows:

- in the use of high-quality components (for example, not hardened cement of the required grade, clean sand with rubble);

- in good mixing the final mixture;

- in keeping the proportions between the components.

Before you prepare a solution, you need to purchase all the necessary materials, having previously calculated their required amount. It will also require water.

The proportions of concrete for the foundation and other monolithic structures are determined by the brand of cement used: the higher it is, the less this component is added to the mix. At observance of the correct ratios, the monolith strength remains at the proper level. When preparing concrete, you should also take into account the moisture content of sand and rubble: if they are wet, then you need to add less water.

Before kneading the solution, place the concrete mixer in a stable position on a flattened, solid surface.It is necessary to locate the equipment closer to the place of its use, so that then you don’t have to carry it far in buckets. Fix the wheels of the unit in a stationary position using the brakes. To unload the finished material An old bath or a large trough will work well - it is convenient to get a solution from them. Each time putting a bucket in and overturning the mixer is an extra job.

Concrete batch It is recommended to perform in the following sequence:

- pour water;

- pour cement;

- add the required fillers (sand with rubble);

- add the necessary additives if necessary (for example, a plasticizer);

- start the mixer for the time specified in the operating instructions for the model used.

The temperature of the concrete mix at the outlet of the concrete mixer should be approximately from +5 to +30 degrees (for different types of cement there may be slight deviations). In this case, the finished material will meet the technological standards.

The preparation of the solution takes some time. The exact duration of stirring depends on the additives added and the consistency of the mixture.Therefore, it is recommended to visually monitor the quality of the material at the outlet, in the presence of lumps increasing the time of its mixing.

Cleaning Concrete Mixers After Work

After operation, an adherent solution remains on the walls of the drum, both outside and inside, from which they need to be cleaned. Work material accumulates also between the blades, contaminates the frame. If you allow the mortar to harden, you will need to beat it up with a hammer or other suitable tools. This removal method leads to the following negative consequences:

- the appearance of dents;

- paint churning, after which the metal begins to rust and corrode at a faster rate;

- the impossibility of complete cleaning (the dried solution remains in hard-to-reach places, for example, in the place where the blades dock with the body).

Also, shock removal has a bad effect on the support bearing, accelerating its failure.

In order to prevent such consequences, it is necessary to clean the concrete mixer from the frozen cement immediately after completion of the work. Timely rinsing is especially important when the mixed composition contains plasticizing agents with improved adhesion: after curing, it is very difficult to remove them.

Washing is recommended not only at the end of the work shift, but also in its process after carrying out a maximum of 2 batches. The cleaning process is best done by pouring water on the pressure of the running concrete mixer. If this is not possible, then you need to pour water into the drum in the required amount and turn it. You can also wipe the walls outside and inside with a rag or brush.

Remaining after washing the dirty water inside the tank can be used for the next batch. It is impossible to leave it inside, because the plasticizer and cement that has settled in the liquid will clutch. After cleaning, turn over the container to let the water glass.

You can reduce the destructive effect of cement mortar and impair its ability to stick to the walls of the concrete mixer drum. For these purposes, before starting work, the inner and outer surfaces of the container should be processed. water-repellent and anti-corrosion compounds. As such materials, suitable silicone or automotive anti-corrosion agent. One-time processing lasts for about 3 months of regular operation of the equipment.After the expiration of this period, it is possible to coat the drum again with a suitable composition.

The main malfunctions of the mixer and their elimination

During operation, various breakdowns occur. In some cases, repair of concrete mixers can easily be made by hand, without recourse to the specialists of the service center. Most often, the failure of concrete mixers associated with the following components and parts.

Gearbox

The breakdown of the gearbox belongs to the category of complex and quite expensive. Often, replacing one gear is not enough. I have to install a new node.

Thrust bearings

To put a new bearing, you first need to remove the drum and gear. After you need to knock the shaft. Then you need to pull off the bearing with a puller. Instead of a worn or broken one, the whole should be placed and the unit assembled in reverse order.

Gear crown or gear that is included with it

Crown may be sectoral or solid form. Replace without disassembling the concrete mixer will only get the item of the first type. To remove the worn drive gear, unscrew the bolt fixing it. Then dismantle this part, replacing it with a new one.

Electric drive

If the electric motor is heated from a hand-held concrete mixer, this may be caused by its overloading or burning of the windings or wedging of the rotor. To determine the health of the electrical part of the engine will help the multimeter. With its help determine the integrity of the windings of the disconnected motor. If a break is detected, you will need to purchase a new motor. In general, the list of problems associated with the electric motor is quite wide. Often, their removal requires special knowledge.

Belt transmission (with pulley or belt)

It is convenient to carry out a belt tension or its change together. The features of the process are determined by the design of the operated concrete mixer. To change the erased plastic pulley, you will need to unwind its fasteners, after removing the container.

Concrete mixer motor start button

Set the health of the start button also helps multimeter. To do this, the button must first be removed and disconnected suitable wiring. After you need to disassemble the button. If the starter coil is intact, then there is a problem in the contamination of the contacts.It is enough to clean them with fine sandpaper to restore button functionality. The burnt coil will need to be replaced with a new one.

Over time, as a result of wear holes are formed in the drum. They are closed with pieces of sheet metal of suitable size by welding or bolting. Infrequently, but the frame (bed) happens to burst. Eliminate breakage using a welding machine. Also rarely have to change wheels.

To repair the equipment with your own hands, you will need to use a variety of tools, devices and accessories. Their approximate list includes:

- multimeter;

- Bulgarian;

- electric drill;

- welding machine;

- hammer;

- pliers and round pliers;

- spanners;

- screwdrivers;

- caliper, ruler or tape measure.

Replacing a bearing that has worn out requires the use of a special puller.

Constant loads, improper maintenance and care, wear of parts over time lead to various kinds of problems with the concrete mixer. At the same time, repair of the concrete mixer can be entrusted to specialists or performed independently.In the latter case, if the unit is not under warranty, then you will save a substantial amount. In order for the operated equipment to serve for a long time without breakdowns, it cannot be overloaded. It is also necessary to pay attention to the first signs of problems and eliminate them in time. Equipment should always be well cleaned of residual adhered solution.

/rating_off.png)