Grinding wheels for grinding and polishing

It is no secret that the Bulgarian is successfully used in the construction industry as a tool for cutting various materials, grinding surfaces, as well as polishing them. For grinders developed many nozzles that significantly speed up and facilitate the workflow when processing wood, metal, stone and concrete. In this article we will look at the grinding and polishing wheels for the angle grinder.

Content

Concrete grinding

When performing construction works, craftsmen often have to remove various irregularities, seams and sagging on concrete surfaces. To make the concrete wall or floor smooth and polished, a special nozzle is used - a diamond cup. They, in turn, have several varieties.Depending on the type of work that needs to be carried out on concrete, the type of nozzle is selected. The following lists the nozzles for treating concrete and other hard surfaces.

Double segment

This nozzle is widely used. for roughing “Wild” stone, brick and concrete walls. The cutting part of the nozzle allows you to eliminate various defects on the above-listed surfaces, as well as cut off non-uniform, thick layers on concrete screeds.

Dolphin

It is considered a more benign tool than sharpened nozzle “Double Segment”. With its help, you can more gently polish the surface. The tool has a small weight, good performance and wear resistance.

Square

It is heavy and targeted. for rough and at the same time high-performance works on concrete. During the operation of the tool, not only the surface is polished, but also the material is chipped off. Due to this, the productivity is increased by several times and the wear of the cutting elements of the nozzle is reduced.

Most often, the grinding wheel "Square" is used to prepare the surface for applying to it various kinds of polymer coatings. This fact is explained by the fact that this nozzle has no pronounced grinding effect. The surface after processing with the “Square” tool remains rough, which increases the adhesion to polymeric compositions.

Boomerang

It is used to perform finishing work and is most popular nozzlebecause it is lightweight and versatile. In performance, the “Boomerang” is not inferior to double-row diamond cutters, but it works more “gently” and steadily. Also using this cup is much easier to align the plane.

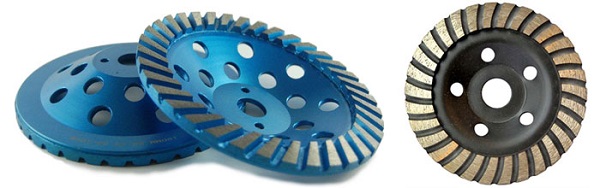

Turbo

The nozzle is distinguished by its high performance, wear resistance. It is mainly used for processing hard surfaces: high hardness, reinforced concrete and dense concrete, marble and granite. Also with the help of the tool “Turbo” you can cut chamfers and edges on marble slabs. In addition, the nozzle for grinding allows professional stone masons to do curly cuts when creating monuments of stone.

Typhoon

It is used for high-speed, coarse and semi-finishing grinding granite, stone, marble and solid concrete.The diamond grinding cup differs in high efficiency and durability. Often used for removing old coatings from concrete surfaces.

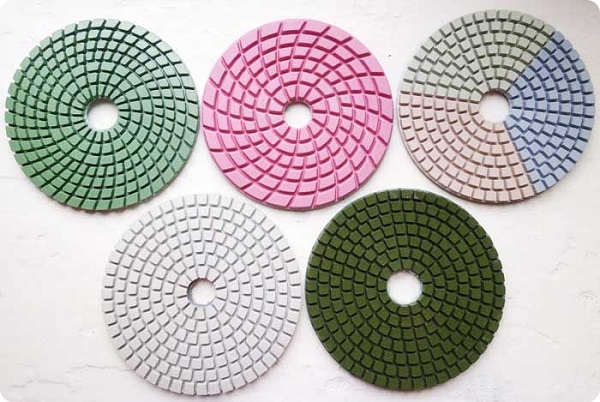

Turtle

Nozzle "Turtle" is applied for polishing granite and marble and giving the surface a specular gloss. Such an abrasive nozzle can have a different grain size, both the largest (for coarse grinding) and very small (for finishing).

Also used for polishing marble circles of felt or felt. All these consumables are attached to the base with velcro.

Metal grinding

To grind or polish a metal surface, special abrasive and polishing wheels are developed for the grinder.

Abrasive grinding wheels are designed for:

- stripping parts;

- sanding surfaces;

- roughing of blanks;

- remove rust.

Abrasive wheels can be petal type or in the form of consumables for special attachments. The petal circle is made in the form of a disk with pieces of emery paper pasted on it. Grit is selected to meet the requirements for the treated surface.

Emery flap wheel is also used for peeling paint from various surfaces and for sanding wood.

Replaceable emery wheels are fixed with Velcro to the base, which is installed on the grinder.

Also for grinding metal often used nozzles made of nylon threads with a special coating, and they are called Clean and Strip. These grinding nozzles are flexible, not clogged, and allow processing in hard-to-reach places.

Polishing tips are designed for:

- giving a metallic surface a mirror finish;

- giving polishing coatings gloss.

Polishing and grinding wheels are also attached with Velcro to a special nozzle for grinders.

Initially, metal grinding is performed emery wheel required grain. Further, if this is necessary, the surface can be polished. To do this, use a polishing wheel (non-abrasive), which can be fabric, felt or foam. Circles are used with polishing pastesthat are applied to their surface. Abrasive wheels are usually used for polishing a car.

If any kind of polishing agent is used for processing the car body, then before applying it it is recommended to glue all the gaps around the headlights with masking tape.

Pipe grinding

For grinding pipes you need to purchase or make the most special roller nozzle on the Bulgarian. The following photo shows how this fixture looks.

With this nozzle for the grinder, you can quickly clean the pipes of rust and paint, align the welds. As consumables for this device use tape sandpaper. In addition, the device can be used as a nozzle for polishing stainless steel pipes. If you wear it felt tapethen the pipe is polished to a mirror finish.

/rating_off.png)