We collect the dehydrator with your own hands

The dehydrator is a device that is a dryer for food (greens, fish, meat, mushrooms, nuts, vegetables and fruits). Also, this device can be used to cook more healthy (dried, without any other processing) food, for example, various desserts, sprouts of sprouted grains, cookies, chips and more. Fans of needlework create with the help of the apparatus dry flower bouquets, papier-mâché objects, herbarium and other decorative crafts. Dehydration of products in the device occurs due to the action of warm air, infrared or sunlight.

Store appliances are quite expensive. They allow you to maintain a constant set temperature inside the drying chamber. Making a dehydrator with your own hands is an opportunity for everyone to save on the device and get a device that allows you to quickly dry the products in the required quantity.

Content

Homemade dryer from the old refrigerator

A homemade dryer can be made from an old refrigerator. This will make a good dehydrator for fruits and vegetables.

Manufacturing algorithm

The process of manufacturing the drying unit from the refrigerator is as follows.

- Carefully dismantle the compressor, radiator and freezer, so as not to damage the tubes and avoid leakage of the working substance (refrigerant).

- Remove the inner lining and insulation, leaving the sealing gum on the door.

- In the place where the compressor was installed, mount the fan.

- Above (on the roof) of the refrigerator they make a hole under the pipe (a two-meter piece is enough with a diameter of 100 mm) or an aluminum corrugation with a length of 3 m, which is fixed with glue.

- A hook is hooked to the door to fix it securely.

- Attach wooden slats to the side walls of the box from the refrigerator with screws or bolts after about 10–20 cm in order to put shelves on them.

- If any holes remain, then they are closed up.

- To speed up the process of drying on the pipe or corrugation put the hood.

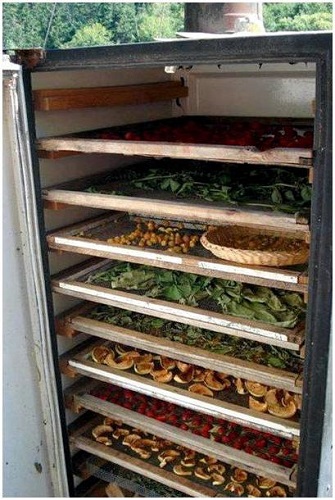

The final construction is shown in the photo below.

Nuances of creating a structure

The inner lining and insulation are removed, because the plastic and the foam decompose when heated with the release of harmful substances.

Dismantle the insulation should be in gloves and a respirator to protect against glass wool (if it served as insulation).

Since the remaining tin cabinet is not particularly rigid, its degree may need to be increased by installing struts or internal galvanized casing.

For blowing products allowed to use the usual exhaust fan 18 W, 125 mm in diameter, only installed to force air inwards. Installing a fan heater will significantly speed up the whole process, increasing the productivity of the installation.Instead, one or two can be attached to the back wall. electric heaters total power up to two kW - then the device will work as an electric dryer. At the same time in the upper part of the box should install a second exhaust fan.

The created unit can be used all year round. But if a conventional fan is installed, then painting the case in black and installing the device in the sun during the warm season increases the temperature inside, which speeds up the whole process of drying products.

In order for the created dryer to work efficiently, it is necessary to ensure good airflow of the product laid on the sheets. This is achieved by leaving a gap of 2 cm between the box and the door on one side and the back wall of the box on the other.

When using a refrigerator with conventional fans without installing heating elements, it is enough to remove only the compressor with the freezer and the radiator. Thus, the slots for installing shelves on them remain, but if necessary, you need to add more. As shelves can be applied:

- grills designed for grilling, but with handles cut off;

- metal sheets with holes drilled into them;

- grids with different cell sizes;

- old mesh shelves from the fridge;

- made of wire or wooden slats lattice structures.

A variety of options for creating shelves for vegetables and other products is easy to come up with on their own and make of scrap materials.

If the compressor is in working condition and the coolant’s circulation system is not damaged, then these parts can be useful for creating freezer do-it-yourselfers.

It takes several hours to create a dryer from a refrigerator, if necessary parts and tools are available. The design can be improved in various ways, equipping, for example, temperature sensors and the simplest automation system, or experimenting with the location of the fans. To protect against the penetration of insects into the drying apparatus, ventilation openings should be closed. mosquito net or gauzestacked in 2 or 3 layers.

Dehydrator from a homemade cabinet

The dehydrator can be made from a home-made cabinet in a manner similar to the previous one.Only instead of the refrigerator there is a cabinet made of plywood. For this you need the following materials:

- plywood or chipboard, fiberboard;

- wooden slats;

- metal corners and screws;

- aluminium foil;

- electric heater;

- 2 fans;

It is better to use a fan heater instead of a separate heating element. Another fan will be normal, while working on the hood.

The cabinet should be designed to provide unimpeded air circulation. It is collected in this sequence.

- Make a frame of the bars of the desired size.

- The box is sheathed from the sides, top, bottom and back of the plywood, fiberboard or particleboard.

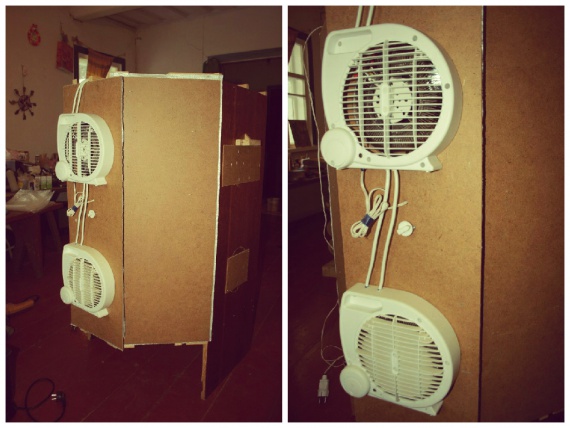

- Hinge the front door of similar materials with many holes, approximately as shown in the photo below.

- The interior of the cabinet is covered with foil.

- Install shelf holders and the pans themselves.

- Mounted in the lower back of the fan heater, and in the upper - an ordinary fan.

Fans can be connected in parallel and turn on the switch. Also, the design can be additionally equipped with lights showing the operation of the installation. The fan heater is equipped built-in thermostat. It will automatically turn on heating of the heating element. If necessary, you can disable one helix to reduce the capacity of the installation.

Simple solar dryer for fruits and vegetables

Solar dryer can be made in various ways. Wherein no electricity costs: vegetables or fruits are dried by the energy of the sun's rays. Summer residents fit the simplest design, which can be done with a hammer, saw, stapler and scissors. The creation of the installation is performed in the following sequence.

- Collect the frame of the desired size, based on the required volume of the workpiece, for example, from wooden bars 50 to 50 mm.

- Sheathe it from the sides and rear plywood or boards.

- The back wall is sheathed from the inside with a metal sheet.

- Paint the inside of black, so that the air gets hotter.

- At an angle that provides the best exposure to sunlight, install shelves made of nets, wire, plywood, tin, plastic and other materials.

- In the upper and lower parts of the design make ventilation holes, the size of which must correspond to the dimensions of the installation.

- Cover them with gauze or mosquito net to prevent insects from entering the drying cabinet.

- The front part of the box is made in the form of a frame fixed on the sheds.

- It is closed with glass, transparent plastic, polycarbonate or plastic wrap (fixed with a stapler).

- Make a stand for a box of bars or metal pipes.

Also, the created structure can be simply rely on something. Possible appearance is presented in the photo below.

In such a cabinet by heating the metal sheet is achieved temperature 40-50 degrees. Ventilation ensures the removal of moisture released from the fruit.

Solar dehydrator with collector

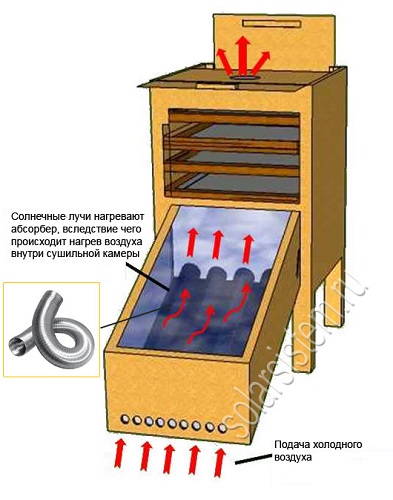

A more complex version of the solar dryer (shown in the photo below) consists of two sections:

- air heating zone, consisting of a collector;

- drying zones where products are located.

The front parts of both zones are covered with a transparent material, for example, glass, polycarbonate.

Collector is a box, the bottom of which is covered with a thin sheet of metal painted black. A heat insulator (mineral wool or sawdust) is placed under it to minimize heat loss.Air penetrates through the ventilation holes into the heating zone. Then he goes up through the shelves with food and goes outside.

By installing black tubes as an absorbent, for example, painted aluminum corrugation, it is possible to increase the temperature of heating the air by the collector.

For the device to work efficiently, it must always be kept directed towards the sun.. If to install collectors from three parties, then need for rotation disappears, such drying unit will work all the day. All slots are sealed with sealant.

Solar dryer with fan and thermostat

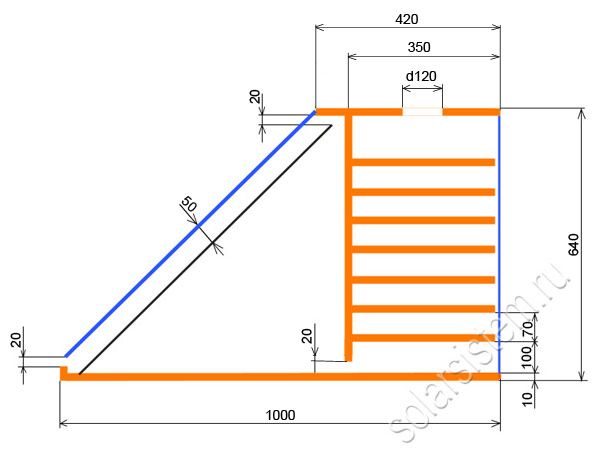

To create a working automated model with a length of 1 m, a height of 0.6 m and a width of 0.53 m, the following materials will be needed:

- glass;

- wooden bars and slats;

- plywood;

- metal corners;

- aluminum sheet;

- fan with a diameter of 120 mm voltage at 12 V;

- mosquito net;

- thermostat (for example, W1209), consisting of a temperature controller and a thermostat;

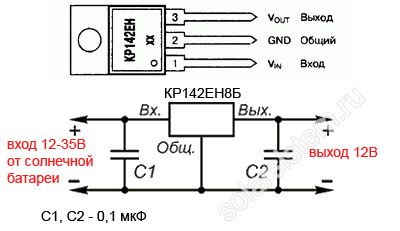

- voltage regulator with microcircuit KR142EN8B;

- a solar cell that outputs a voltage of 12 V;

- metal grid for pallets.

It is recommended to use temperature controllers equipped with two temperature sensors to monitor the temperature at the top and bottom of the box.

The scheme of the device is presented in the photo below.

The algorithm for the construction of the following.

- According to the scheme above, a frame of bars and plywood is assembled, connecting the individual elements with self-tapping screws, metal corners.

- Seal the made body.

- The wheels are attached to the bottom (with a diameter of 40-100 mm) so that it is convenient to rotate the structure according to the sun.

- Make the rear door of glass, so that you can lay products, as well as to observe the process of drying.

- Install through 7 cm seven shelves.

- Do shelves of mosquito or steel mesh and rails.

- An aluminum sheet is laid on the collector panel, having painted it with black heat-resistant paint.

- Mounted on top of the fan.

- Assemble an electrical circuit, interconnecting a stabilizer, a solar battery, a thermostat and a fan, as shown in the diagram below.

- Adjust the controller to the desired operating temperature.

The door must be sealed so that insects do not penetrate.

The stabilizer is needed to maintain a constant voltage on the fan contacts of 12 V. Further improvement of the design is possible by fan speed adjustment. It is recommended to rotate the device so that the collector and the battery are constantly illuminated by sunlight.

Build infrared dryer

An infrared dryer is suitable for mushrooms, vegetables, nuts and fruits. It is enough to make it yourself. This will require the following materials:

- iron wire with a diameter of 5 to 8 mm;

- carton made of cardboard, for example, from a vacuum cleaner;

- aluminium foil;

- metal mesh;

- cartridge under the bulb;

- awl;

- screwdriver;

- self-tapping screws;

- cartridge under the usual light bulb with mounts;

- thermometer;

- infrared light;

- aluminum tape or glue.

Installation create in the following sequence.

- The inside of the box is glued with aluminum foil using adhesive tape or glue.

- From a grid by the size of a box do shelves.

- On any wall near the bottom, make a hole for the power wire and fix the cartridge with self-tapping screws.

- Screw the infrared light bulb.

- A thermometer is attached to any sidewall.

- Cut the wire into pieces that are approximately 5 mm longer than the width of the box.

- Pierce the holes in the side walls under the rods for the racks.

- Insert the wire into them and stick it outside with protruding ends with tape.

- Stacked shelving.

In the end, after all the manipulations you get an installation similar to that shown in the photo below.

The temperature recommended for drying fruits and vegetables is 40-45 degrees. It is regulated by turning the light on or off, or by opening the top.

The lid can be the side parts of the box, or it is made separately from the same cardboard. If you want to automate the design, you should use temperature sensor. Under his control the light will turn on automatically.

You can also use an incandescent lamp (its sufficient power is 60 W) or heating tapeused to create warm floors. In the latter case, at home, a piece of 50 by 100 cm with a power of 110 watts is sufficient. In general, the length of the fragment is selected by the used box.

When using the film will need more:

- insulation, for example, bitumen, used in the creation of warm floors;

- a set consisting of 2 clips, two grommets and as many terminal-rings, which is designed to connect the power to the film.

PVC tape is laid on top of bitumen insulation. To connect the film, you need to solder the wires and contacts.

This dryer allows you to achieve temperatures of almost 60 degrees. It can be rolled up and laid on the bottom of the box, made earlier in this way.

Dehydrator for meat and fish do it yourself

Dryer for meat and fish is easy to make from a plastic container. For this you will need:

- fan;

- plastic container with lid;

- steel rods with a cross section of 5 mm or studs with thread washers and nuts;

- a piece of pipe or coupling.

The whole process of making a dehydrator for drying fish, meat and drying other products from a plastic container is shown in the video:

The dehydrator for fish, meat, vegetables, fruits and other products is very easy to assemble from scrap materials: plywood, boxes, refrigerator. For blowing fit various working old fans. In each case, it will be necessary, of course, to think of a way to fix them, but economic costs will be reduced. In small-sized installations, you can use a fan from a computer, after providing the necessary supply voltage. If you automate the dryer, then according to its functionality, it will be able to compete with factory analogues. When drying meat and fish, it is imperative to prevent the possibility of flies entering the interior of the installation, so that they do not spoil the products.

/rating_off.png)