What to do if the blender broke

What to do if the hostess has broken her favorite assistant - a blender, but at this time the workshop is not working, and the service center is far away? Despite the warnings, many are hesitant to do the repairs themselves. Consider how you can return the device to life at home.

Knife replacement

If suddenly stationary blender stopped cutting products, you need to carefully inspect the knife. In the event of a breakdown, it will have to be changed. If he is blunt, enough sharpen, but sharpening is usually done on special equipment. In any case, this repair will have to start with the removal of the knife (for this you need to know how does blender work).

To remove a failed knife, you must:

- disassemble the bowl if necessary;

- unscrew the nuts securing the knife:

- if there are no nuts, immediately unscrew the knife.

When removing the knife, it is necessary to wrap it with a dense clean cloth so as not to cut the fingers. When disassembling, carefully inspect the bowl. There are models with non-separable bowls. In this case, you will have to change the last one with the knife. Do not forget with the knife to change the gland.

Nuts of fastening of a knife, as well as a knife, have the left carving. It is necessary to unscrew them clockwise, and tighten the opposite - counterclockwise.

Speed switch malfunction

To check and repair the gearshift on stationary or submersible blender, you need a little understanding of radio engineering and be able to use a soldering iron. At home, a complete check of this node cannot be performed. And this must be done. For repair, it is necessary to drop the board and “ring out” it. If, when switching, the contacts are alternately closed (clicked), the switch is in working condition. If this does not happen, you will have to repair it in a workshop or service center.

Do not forget about blocking from switching on without a bowl. Otherwise, you can throw out a fully functional part.

Engine failure

Sometimes it happens that the blender does not want to work at all.There are several reasons. First, blocking the absence of a bowl can fail. In this case, it is enough to listen to the included blender. If you hear a quiet buzz, and the knife is still in place, it is possible that the locking mechanism worked. It is necessary to remove the bowl, and press the lock button with a long object (for example, a pencil). If the blender did not work after that, then most likely the problem is engine. Most likely that the winding burned. In this case, the only way out is to change the engine.

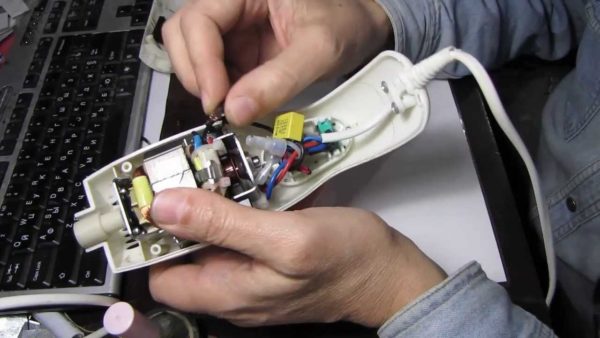

If lucky, and the engine was in good condition, go to the next stage of the test. First, make sure that the outlet voltage still there. To do this, we include in it another electrical appliance. If it works, then everything is fine with the outlet. The next stage is verification. power cord blender. The work is simple, but you will have to disassemble the case (here may be useful tips on disassembling Bosch submersible blenders ). By the way, before you do this, you must make sure that fuse. If it burned out - we change it to the same. Often after performing these simple operations, the blender starts working.

The fuse must always be rated. Installing homemade fuses ("bugs") leads to a fire.

If this operation has not restored the operation of the unit, continue to check power cord. Turning on the plug to the outlet, it is necessary to measure the voltage suitable to the fuse or to the power connector with a voltmeter (tester). If the voltage is - then the power cord is working. If not, then you just need to replace it with a new one.

There are power connectors, completely filled with plastic, without access to the contacts. In this case, you can carefully insert needles with wires soldered to them through the insulation of wires and connect them to a voltmeter.

Sometimes this situation happens: when you turn on the plug in the socket, the fuse immediately burns. This means that a short circuit has occurred inside the instrument. It can be in the engine or in the block of the electronic system. Repair in this case is simple: having determined the location of the circuit or the open circuit, you need to replace the faulty unit. If the problem is engine - we change it, if in electronics - we change fee. Determine the failure of the electronic board is also not difficult. We need to carefully examine it.If during the inspection revealed swellings of capacitors, carbon deposits on the resistors or breaks and peeling of the conductive paths of the printed circuit board, then we can safely assume that the fault lies precisely here.

Before repairing the device must be disconnected from the network.

Dribble in bowl

Rarely, but sometimes there is such a picture - the blender works fine, but puddles appear around. Such a malfunction usually occurs during the flow of the gland. Repair is to replace it with a new one. However, before replacing, make sure that there are no cracks in the bowl.

Never load the bowl completely. In this case, flow from under the cover is inevitable.

The blender is pretty simple. As you can see, it is enough to repair one node, and the device’s operability will be restored. Along with the benefits, making repairs yourself is also fascinating.

/rating_off.png)